Cabinet bearing mechanism used for communication cabinet

A technology of bearing mechanism and communication cabinet, applied in the direction of support structure installation, etc., can solve the problems of difficult processing, non-adjustable width, reduced versatility, etc., and achieve the effect of simple and convenient connection, high efficiency and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

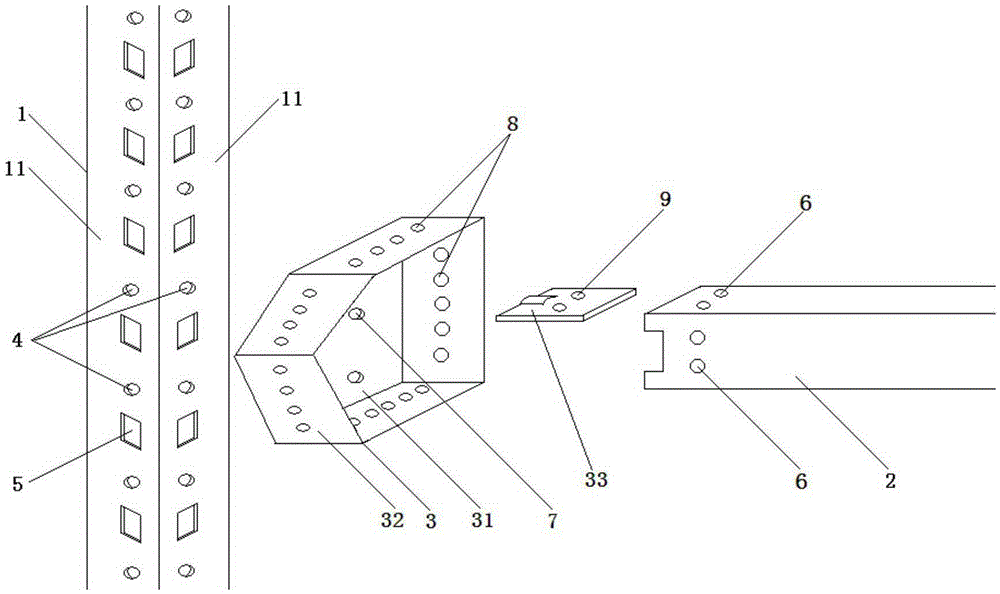

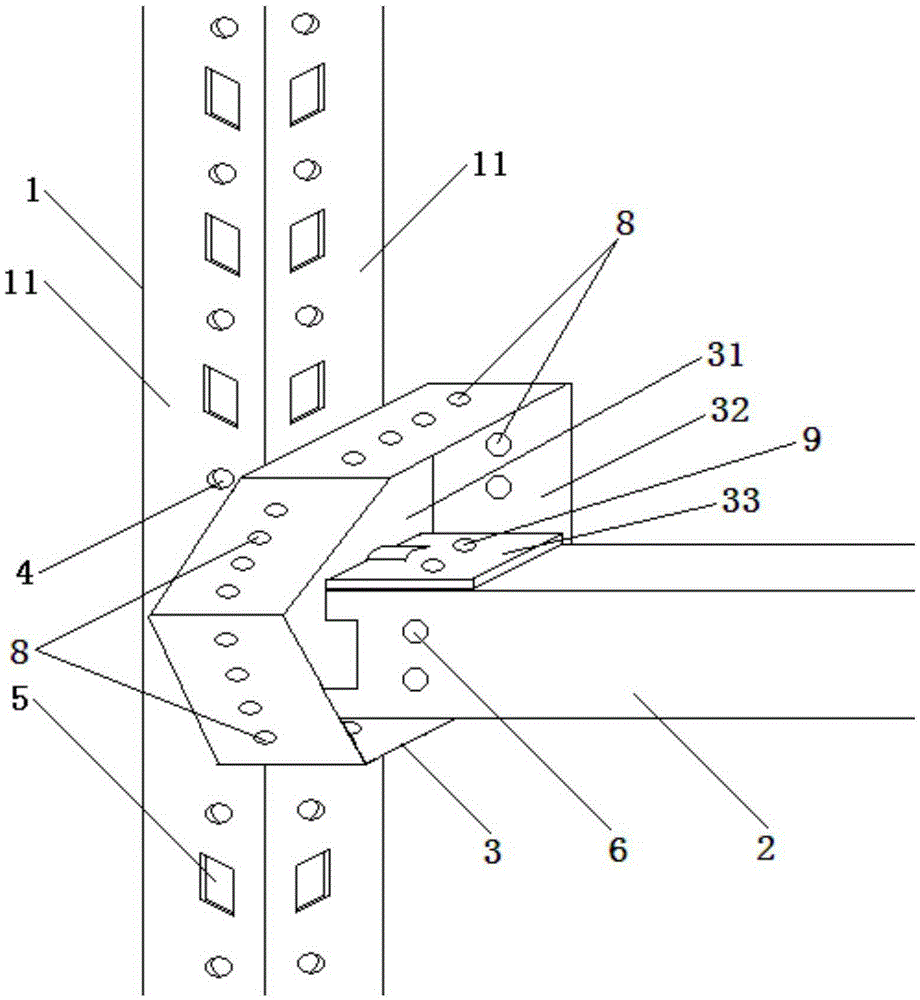

[0024] Below in conjunction with accompanying drawing of description, the present invention will be further described.

[0025] Such as figure 1 with figure 2 The shown load-carrying mechanism suitable for the communication cabinet includes a vertically distributed column 1 and a horizontally distributed installation bar 2, and the installation bar 2 is connected to the column 1 through an adapter plate 3; There is at least one row of equidistant through holes on the cylinder surface, the column 1 is a hollow square channel, and two rows of equally spaced circular bolt hole-shaped channels are opened on the column surface 11 along the axial length direction of the column 1. Hole 4, two rows of through holes 4 are respectively located on adjacent two cylindrical surfaces 11; the cylindrical surface 11 of the column 1 along the axial length direction is provided with square holes 5 that are coaxial and equidistantly distributed with the through holes 4, so that The square hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com