a soybean milk machine

A soymilk maker and motor base technology, which is applied to kitchen utensils, household utensils, beverage preparation devices, etc., can solve the problems of large particle residue and uneven particle, and achieve high-quality production, convenient operation, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

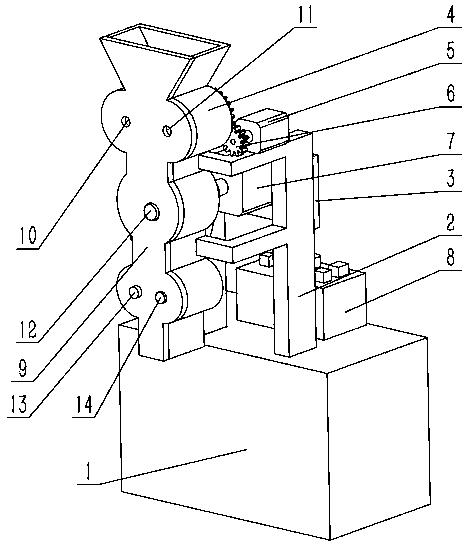

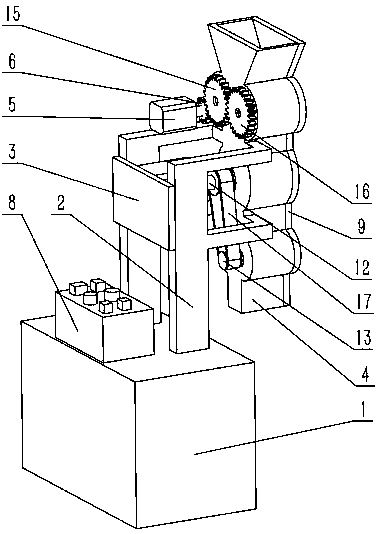

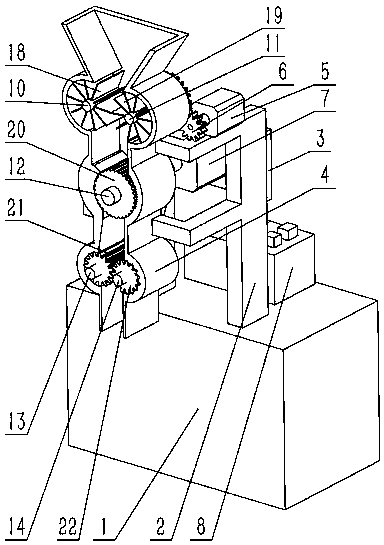

[0012] Such as figure 1 , figure 2 , image 3 As shown, a soymilk machine includes a base body 1, a bracket 2, a grinding motor 7, a jogging motor 5, a grinding motor seat 3, a jogging motor gear 6, a grinding cylinder 4, a grinding cylinder end cover 9, a jogging main gear 15 and a jogging motor gear 6. Send from gear 16, jog main gear shaft 10 and jog from gear shaft 11, primary grinding gear shaft 12, secondary grinding main gear shaft 13 and secondary grinding slave gear shaft 14, primary grinding gear 20, secondary grinding Main gear 21 and secondary grinding slave gear 22, belt 17, main tardy wheel 18 and slave tardy wheel 19, console 8. The support 2 is fixedly mounted on the upper part of the substrate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com