Oil cooler chip wrapping mold

An oil cooler and chip technology, which is applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as the inability to ensure mutual closeness, and achieve the effects of preventing lack of welding, ensuring quality, and eliminating interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

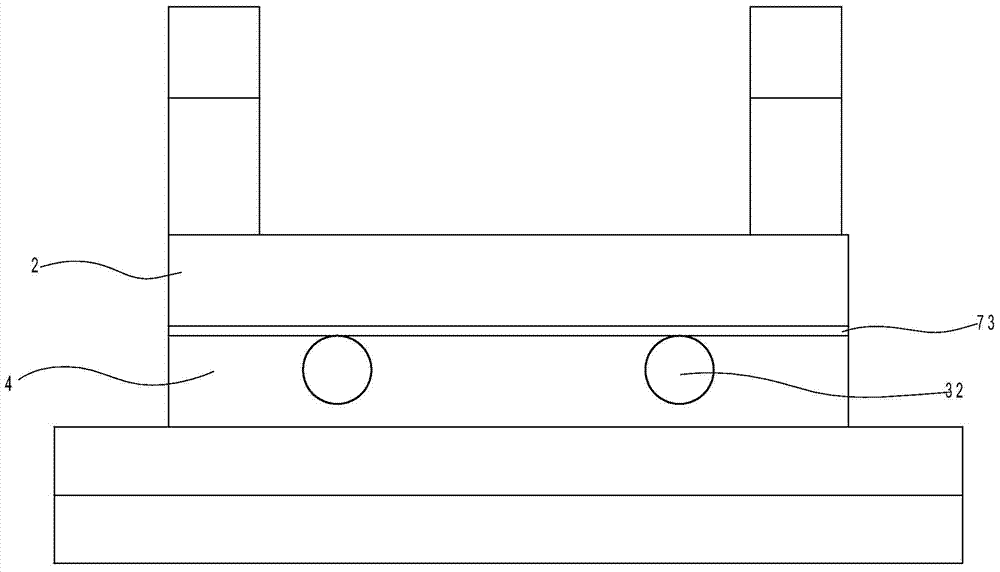

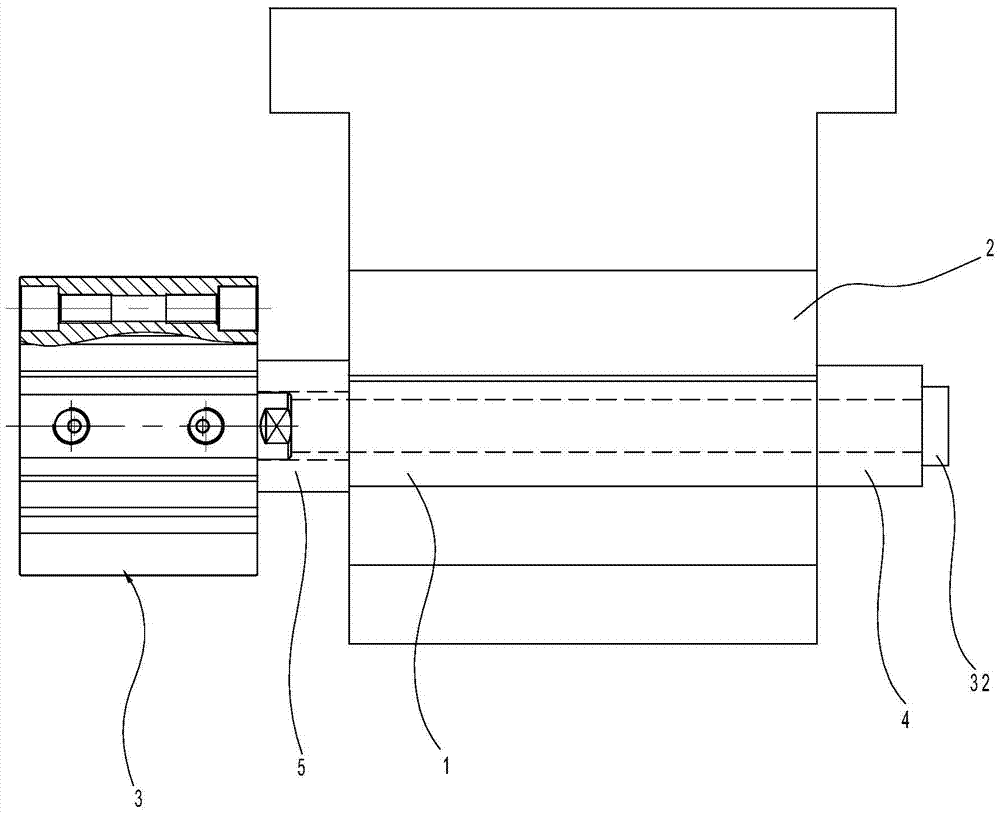

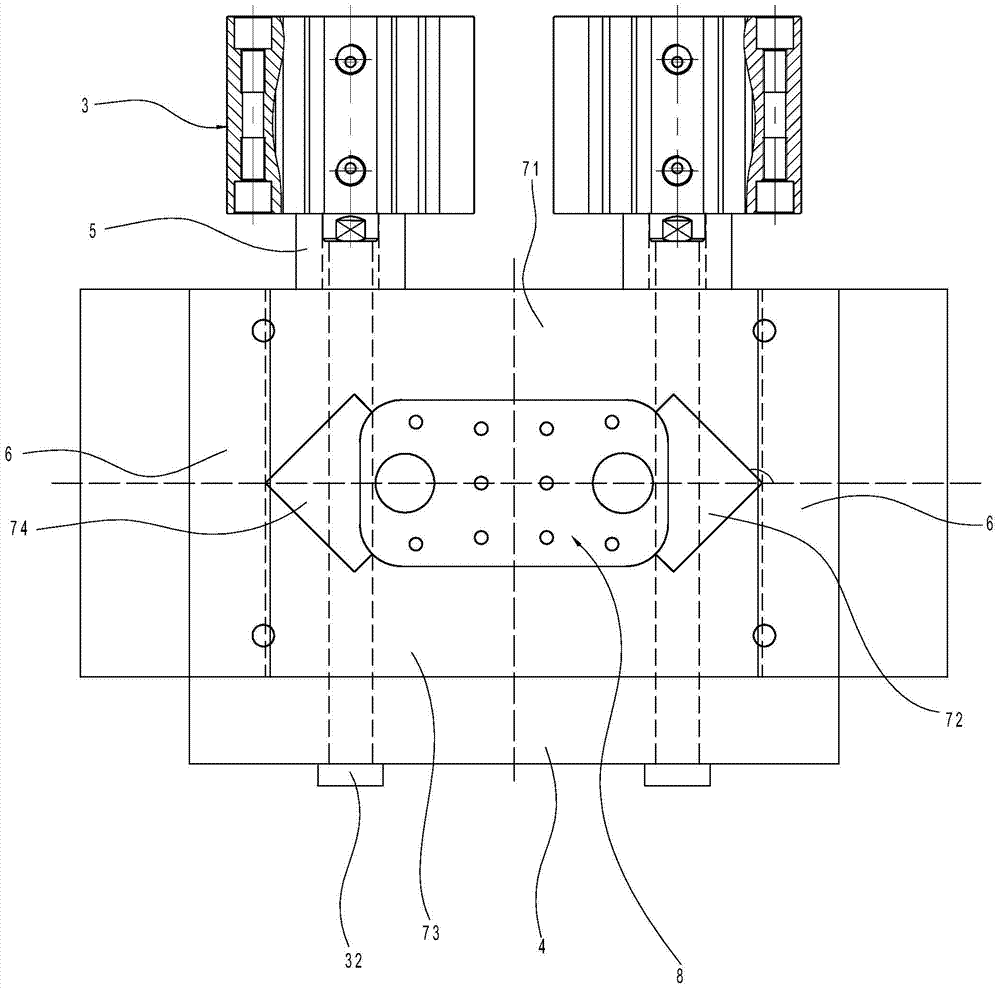

[0024] Such as Figures 1 to 7 As shown, the engine oil cooler chip wrapping mold in this implementation includes a fixed mold 1, a movable mold 2, a first sliding sheet body 71, a second sliding sheet body 72, a third sliding sheet body 73, and a fourth sliding sheet body 74. Locking element 3, spacer 5, cushion block 4, limit block 6.

[0025] Wherein, the oil cooler chip 8 that needs wrapping is placed on the fixed mold 1, and the first sliding sheet body 71, the second sliding sheet body 72, the third sliding sheet body 73 and the fourth sliding sheet body are arranged on the fixed mold 1. The sliding sheet body 74, in order to facilitate the processing and molding of the sliding sheet body, the first sliding sheet body 71 and the third sliding sheet body 73 have the same shape, the second sliding sheet body 72 and the fourth sliding shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com