Tube conveying device for machining of electrical heated tube

A technology of transmission device and electric heating tube, which is applied in the attachment device of shearing machine, shearing device, metal processing equipment, etc., can solve problems such as being unable to meet modern industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

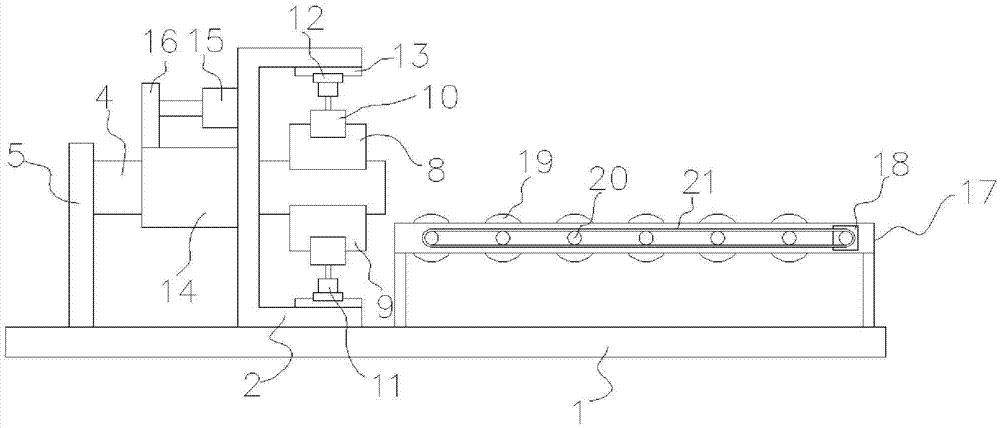

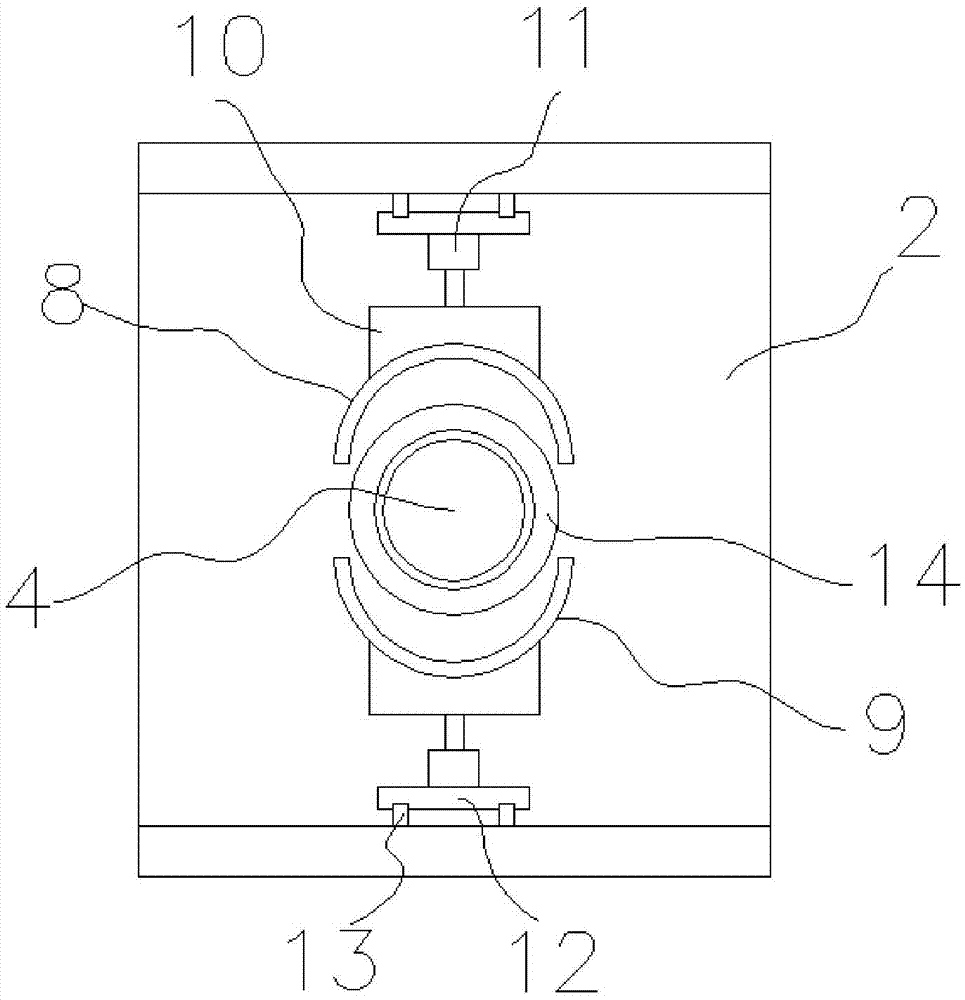

[0020] Such as figure 1 and figure 2 The shown pipe transmission device for electric heating tube processing includes a base 1, a U-shaped bracket 2, a pipe clamp, a support cylinder 4, an ejector sleeve 14, a transmission bracket 17 and a roller transmission device. The U-shaped The bracket 2 is connected to the base 1, and the pipe clamp is composed of an upper clamp 8 and a lower clamp 9, and the upper clamp 8 and the lower clamp 9 are respectively connected to the upper and lower side walls of the U-shaped bracket 2 through a clamping mechanism. Above, the support cylinder 4 is placed horizontally, one end of which passes through the U-shaped bracket 2 and extends between the upper clamp 8 and the lower clamp 9, and the other end is connected with the support plate 5, and the support plate 5 is vertical Connected to the base 1, the side of the ejection sleeve 14 is annular, the ejection sleeve 14 is set on the outside of the support sleeve 4, the inner wall of the ejecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com