Torque wrench provided with locking device

A technology of locking device and torque wrench, which is applied in the field of torque wrench, can solve problems such as inconvenient use, deformation and damage, and achieve the best convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to illustrate the central idea of the present invention expressed in the column of the above-mentioned summary of the invention, it is expressed in specific embodiments. Various objects in the embodiments are drawn according to proportions, sizes, deformations or displacements suitable for illustration, rather than drawn according to the proportions of actual components, and are described first.

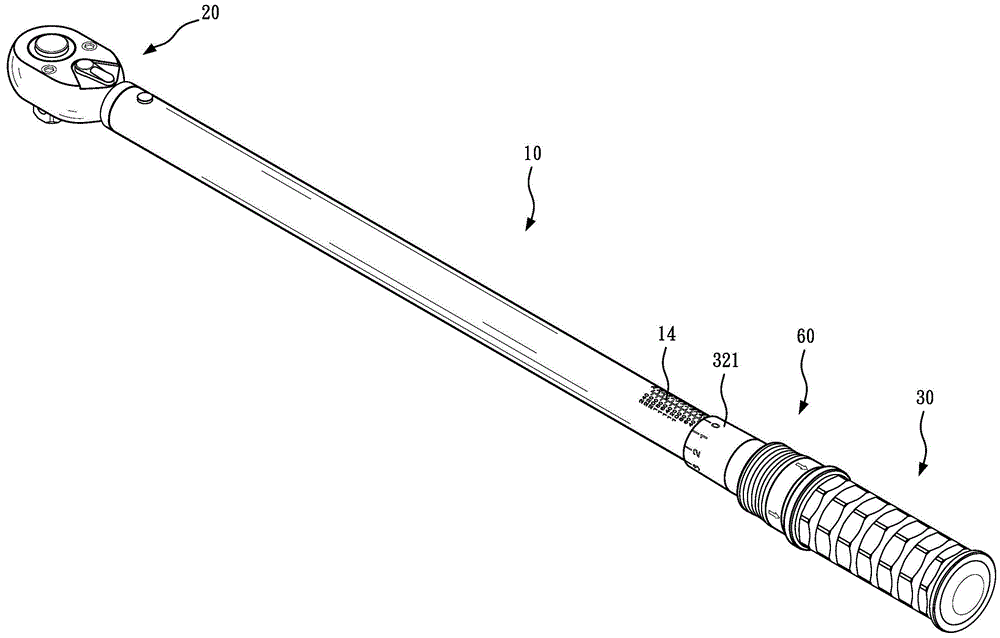

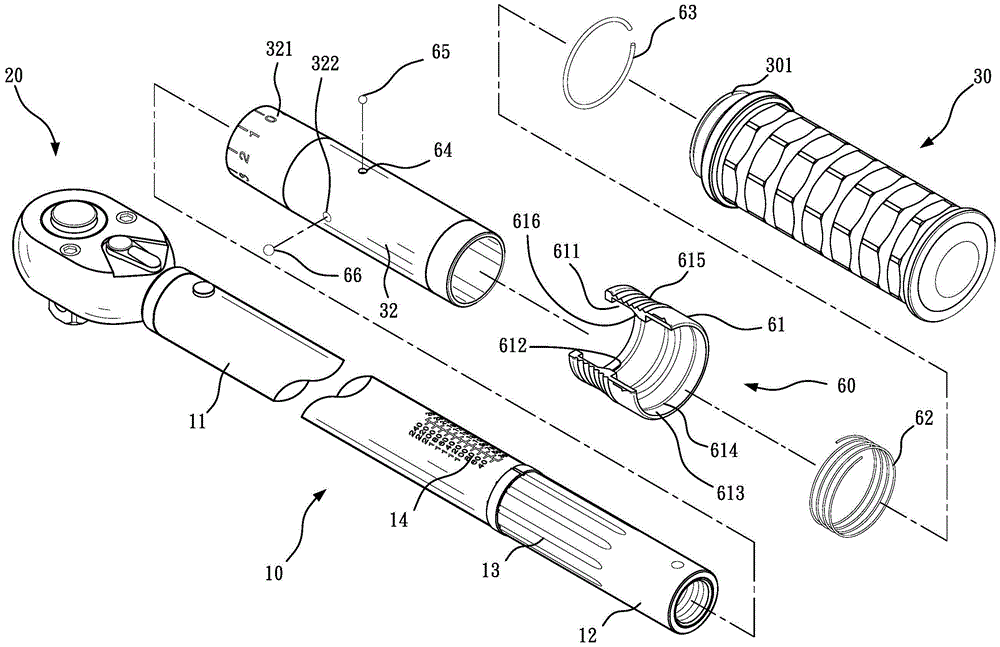

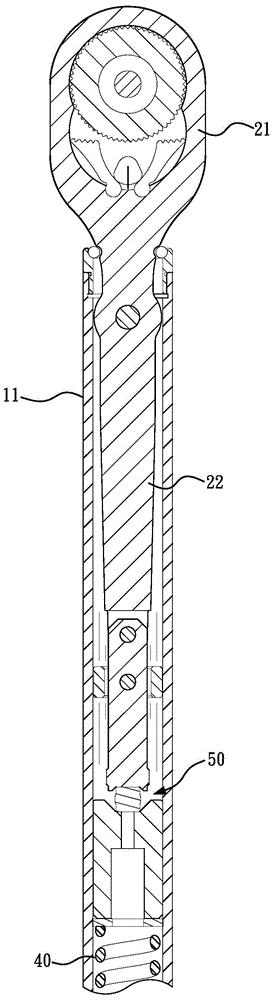

[0044] Such as Figure 1 to Figure 4 As shown, the present invention is a torque wrench with a locking device, comprising:

[0045] A hollow main rod body 10 includes a first end 11 and a second end 12 . Wherein, a plurality of positioning grooves 13 are recessed on the outer periphery of the second end 12 parallel to the axial direction, and a plurality of torque value display numbers 14 are further provided on the periphery of the main rod body 10 .

[0046] A tool piece 20 includes a head section 21 and a rod section 22 , the head section 21 can be a tool such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com