Assembling method for airfoil total composite transonic flutter model

A technology of flutter model and assembly method, which is applied in the field of assembly of airfoil full-composite transonic flutter model, can solve problems such as difficulty in ensuring accuracy, high cost, and difficulty in ensuring surface quality, so as to shorten the manufacturing cycle and ensure design performance, simulated accurate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

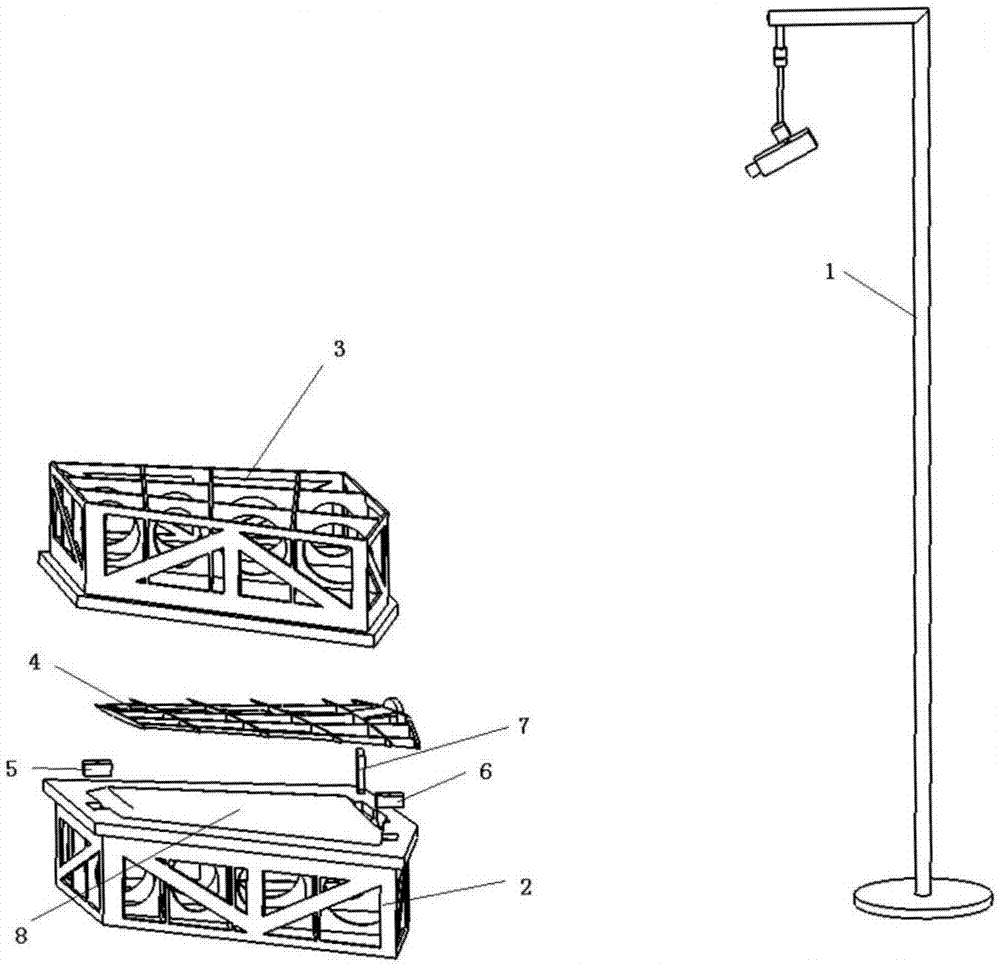

[0021] In the first step, each component of the model is pre-assembled after being solidified and molded individually according to the design requirements, and the components are placed on the metal skin mold (2) with a single-sided composite skin (8) using the laser-assisted positioning system (1). Projection to complete the precise positioning of the assembly position of each component;

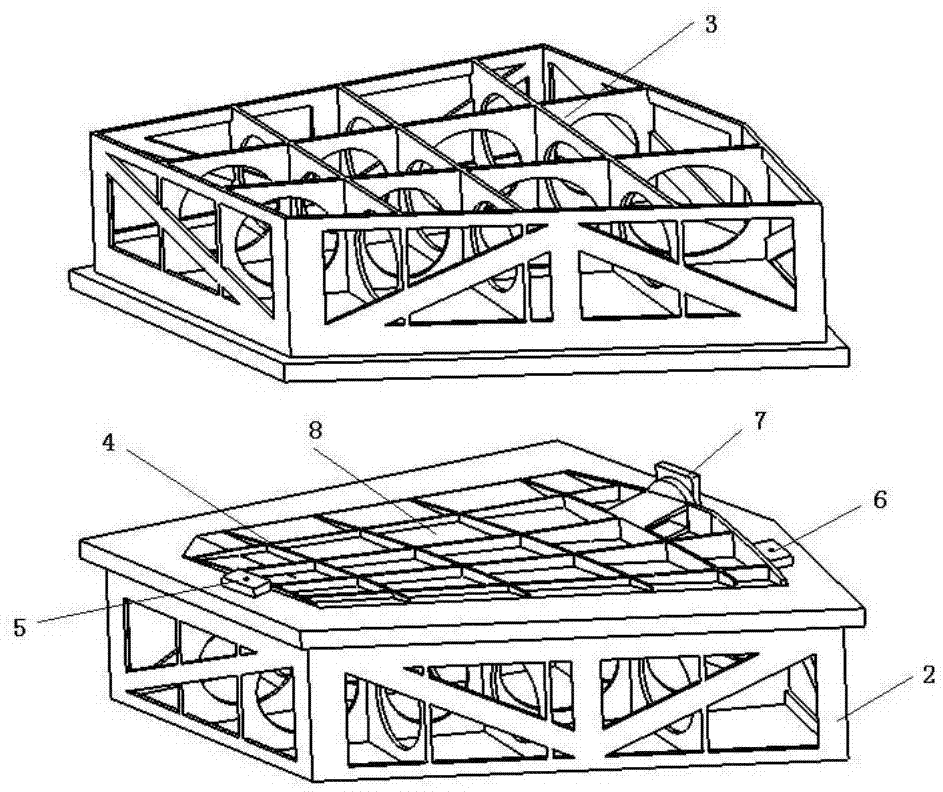

[0022] The second step, such as figure 2 As shown, after the positioning is completed, lay an adhesive film on the assembly surface of the composite component to be assembled, and then use aluminum alloy or composite connecting angle piece to fix the connection position of each component. During the whole pre-assembly process, the positioning position must be compared. After the pre-connection of each component is completed, the model skeleton (4) is formed, and the metal limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com