Bag making machine edge-folding and pressing-down device and component thereof

A bag making machine and lamination plate technology, which is applied in container manufacturing machinery, packaging, transportation and packaging, etc., can solve the problems of single pressing down selectivity, easy to form scratches on the packaging film, inconvenient relative movement, etc., so as to avoid scratches. scar effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

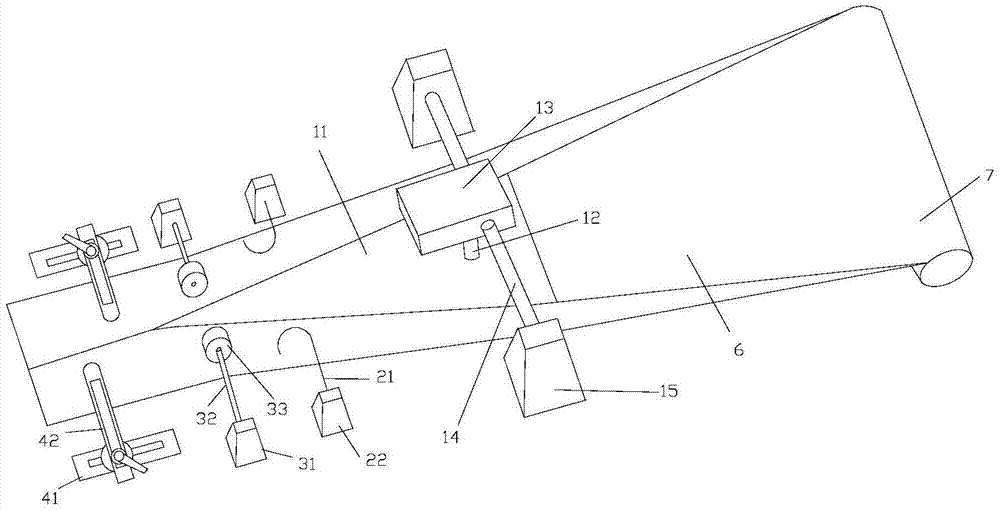

[0024] Such as figure 1 As shown, the embodiment of the present invention includes a pressing device, a pre-folding device, a folding device, and a crimping device in sequence from front to back according to the process flow.

[0025] The pressing device comprises a lower pressing plate 11 , a straight rod 12 , a fixed plate 13 , a cross bar 14 and a third support 15 . Two third supports 15 are symmetrically arranged on both sides of the packaging film 6, one end of the cross bar 14 is fixed on the upper end of one third support 15, and the other end of the cross bar 14 is fixed on the upper end of the other third support 15 . Fixed plate 13 is arranged on cross bar 14, and the top of straight bar 12 links to each other with fixed plate 13, and the bottom of straight bar 12 links to each other with the top of lower pressing plate 11, and the bottom of lower pressing plate 11 presses down on the middle part of packaging film 6.

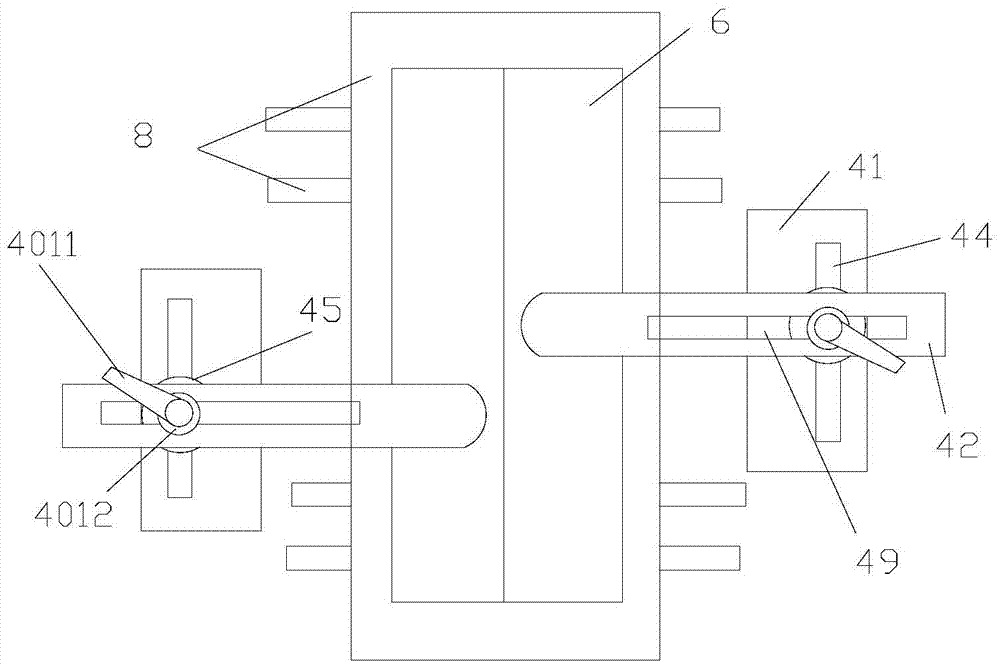

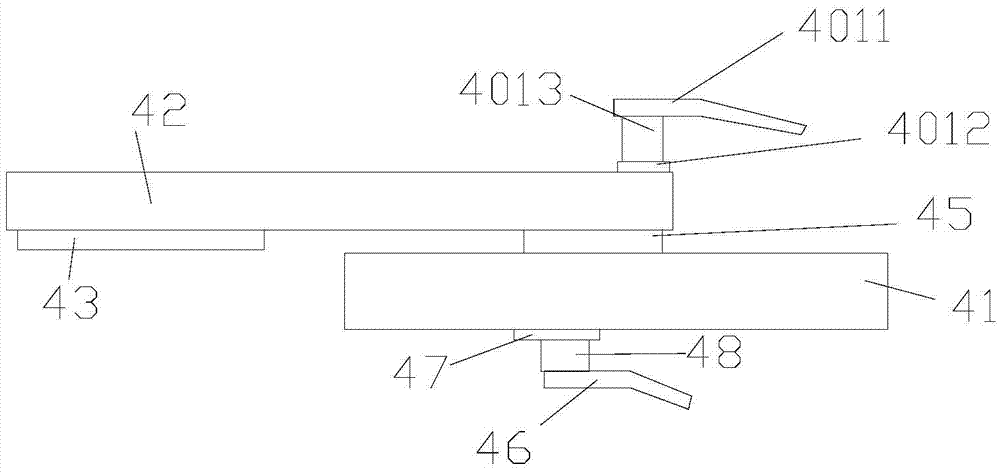

[0026] The pre-folding device is symmetrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com