Refueling auxiliary device

A technology for auxiliary equipment and fuel fillers, which is applied in the direction of funnels, packaging, liquid handling, etc., to achieve the effect of easy manufacture and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

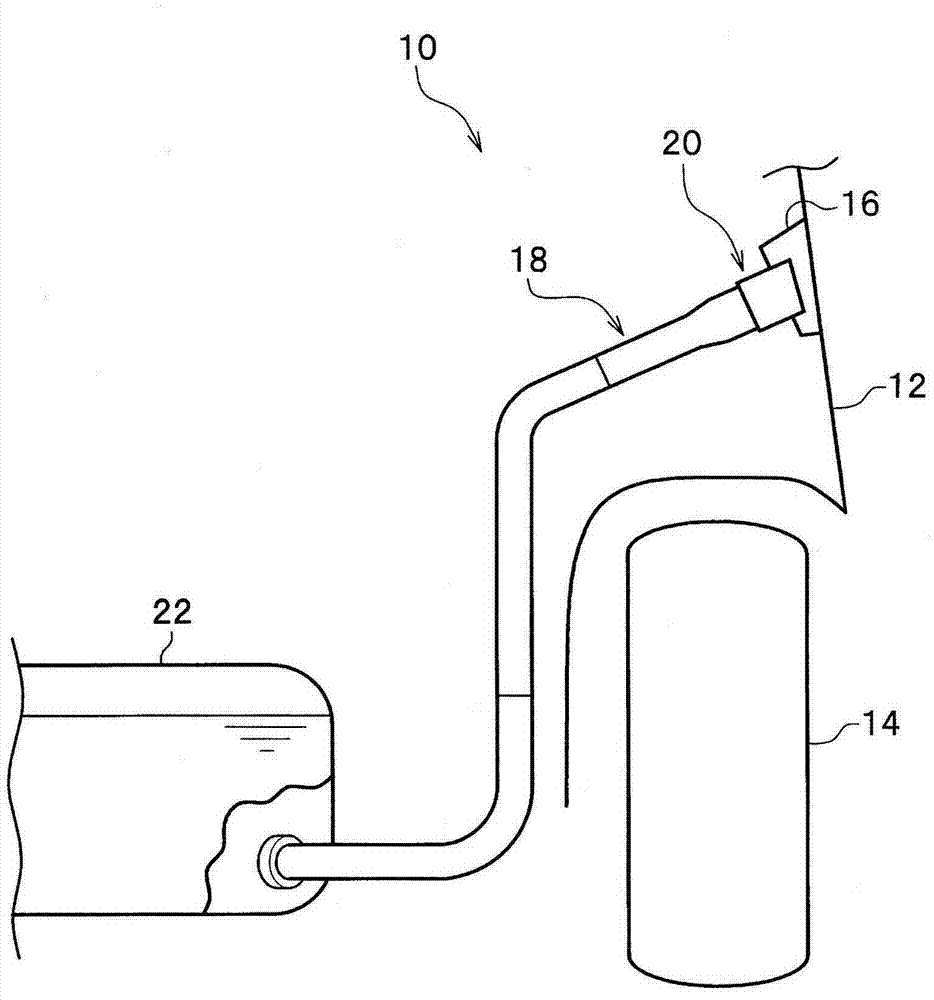

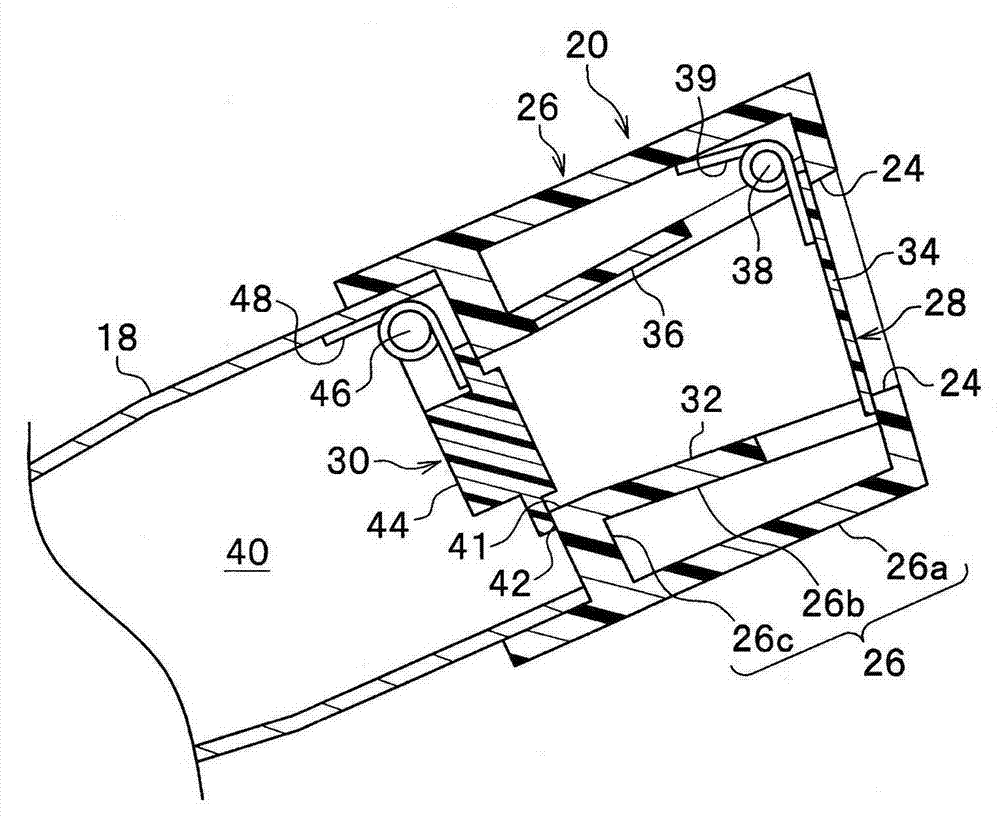

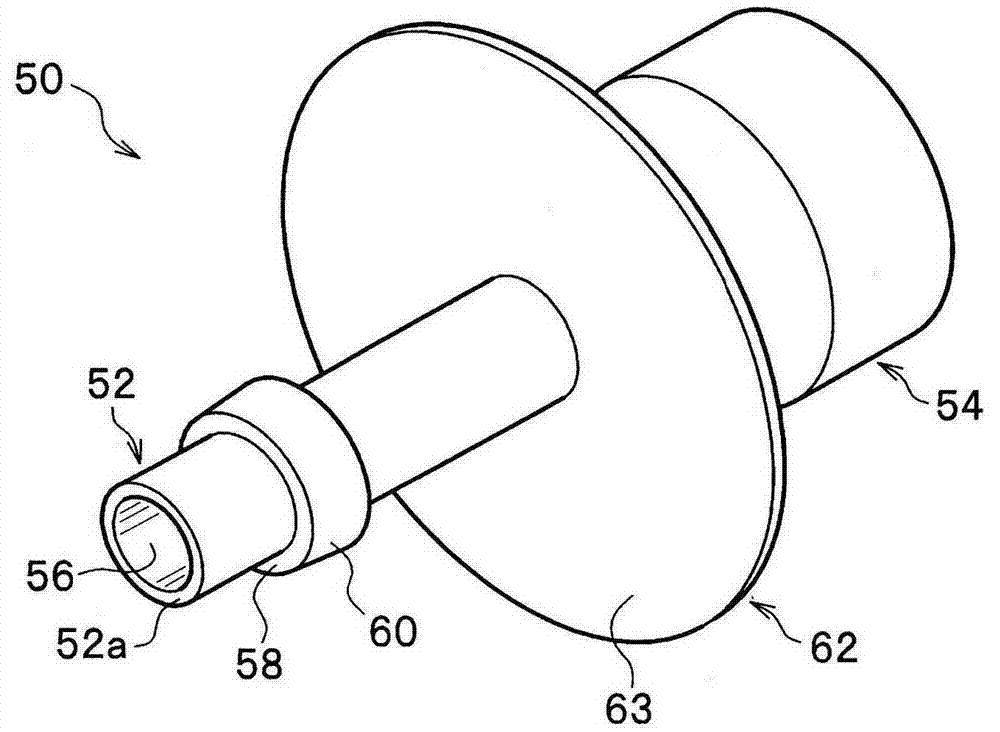

[0042] Next, embodiments of the present invention will be described in detail with reference to the drawings as appropriate. figure 1 It is a schematic block diagram of the refueling structure including the capless refueling mechanism into which the refueling auxiliary tool according to the embodiment of the present invention is inserted, viewed from the rear of the vehicle, figure 2 yes figure 1 An enlarged cross-sectional view of the capless refueling mechanism shown.

[0043] Such as figure 1 As shown, the refueling structure 10 is, for example, disposed on a rear fender 12 located at the rear of the vehicle body. An adapter 16 , which is positioned above the rear tire 14 and has an opening, is mounted on the inner side in the vehicle width direction of the rear fender 12 . On the side of the rear fender 12 facing the adapter 16 , a cover (not shown) is attached through a hinge so as to be openable and closable.

[0044] and, if figure 2 As shown, the refueling struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com