Panel joint structure

一种接合结构、面板的技术,应用在上部结构、上部结构分总成、上部结构分总成之间的连接等方向,能够解决接合部长度变短、接合强度变低等问题,达到提高可成形性、增强接合强度、增强放气效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

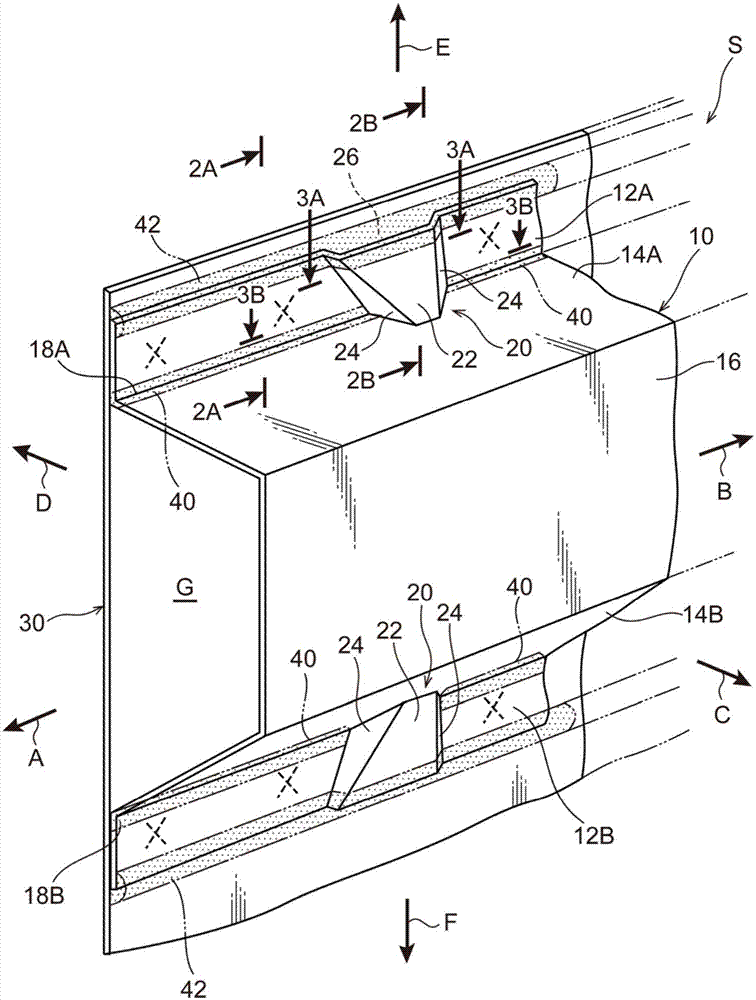

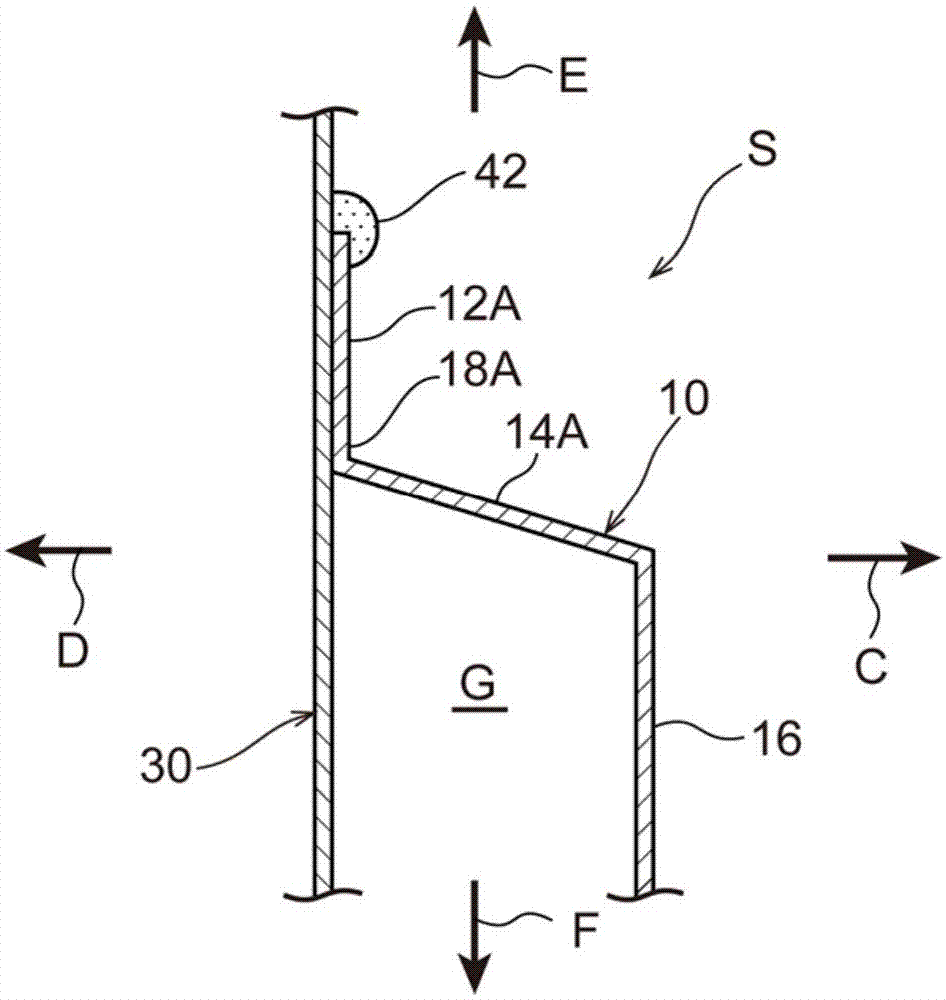

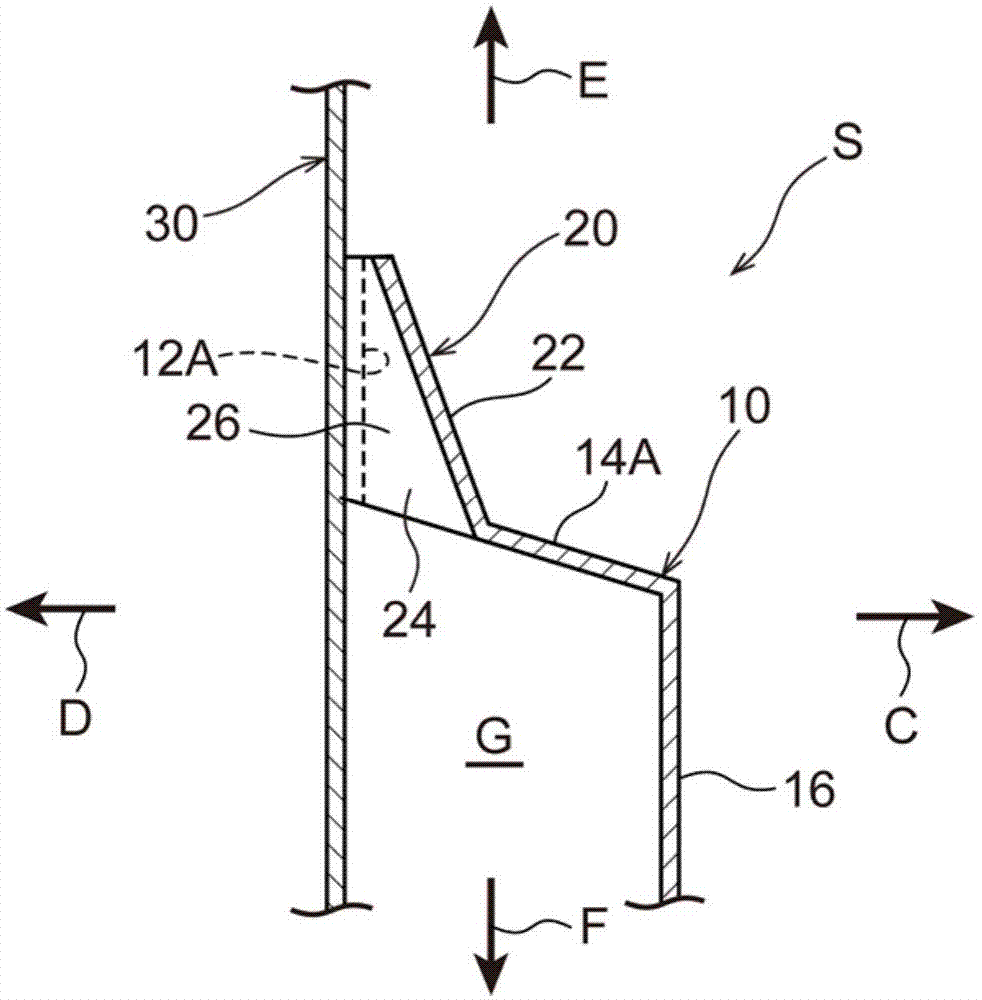

[0054] The panel joining structure S related to the embodiment of the present invention will be described below using the drawings. Such as figure 1 As shown in , the panel joint structure S is applied to the joint between the first panel 10 and the second panel 30 . In addition, the first panel 10 and the second panel 30 are members configuring the lower part of the vehicle (automobile). That is, for example, the first panel 10 is a skeleton member such as a cross member whose longitudinal direction coincides with the vehicle width direction of the vehicle, or a side member whose longitudinal direction coincides with the vehicle front-rear direction, and, for example, The second panel 30 is a floor panel configuring a floor of the vehicle. These will be specifically described below.

[0055] The first panel 10 is constructed of steel plate and along figure 1 The direction of the arrow A and the direction of the arrow B are formed in a substantially elongated shape. In ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com