Packing box set for double-glass solar assemblies

A technology for solar modules and packaging boxes, which is applied in packaging, internal accessories, transportation and packaging, etc., can solve the problems of cumbersome packaging, transportation or unboxing process of double-glass solar modules, difficult to operate, easy to dump safety, etc. The unpacking process is convenient and fast, easy to operate, and the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

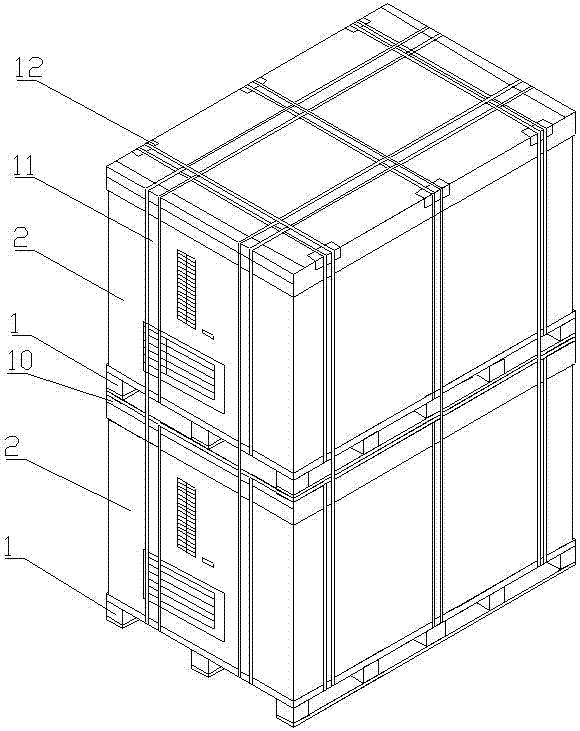

[0032] see figure 1 , the present invention relates to a packing group of double-glass solar modules, which includes two double-glass solar module packaging boxes stacked up and down, and a wooden board 10 is arranged between the two double-glass solar module packaging boxes, and the wooden board 10 ensures that two The double-glass solar module packaging box is evenly stressed to ensure the quality and safety of the stacked modules. The outer sides of the two double-glass solar module packaging boxes are bound by a plurality of packing straps 11 . A protective sheet 12 is also arranged on the edge of the packing belt 11 and the packaging box of the double-glass solar module.

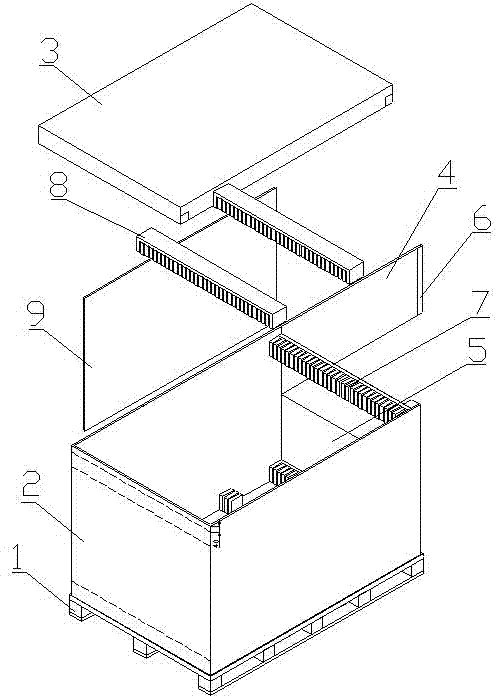

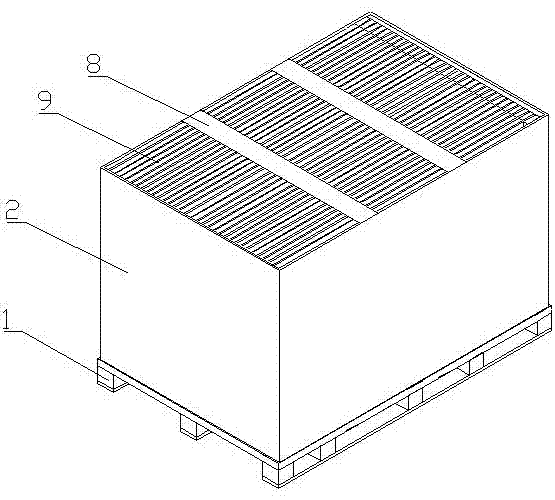

[0033] see figure 2 , the double-glass solar module packaging box includes a tray 1, the tray 1 is a wooden tray, and a corrugated packaging box is arranged on the tray 1. The corrugated packaging box includes a box body 2 and a box cover 3. The box body 2 The rear side panel comprises the movable p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com