Sponge fitness site and construction method thereof

A site and sponge technology, applied in the directions of roads, pavements, roads, etc., can solve the problems of shrinkage, large expansion coefficient, poor water seepage and water storage capacity, not conforming to sponge city, etc., to reduce pressure, not easy to dust, and good elasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

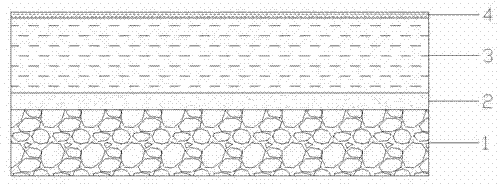

[0020] like figure 1 , the present invention relates to a kind of sponge gymnasium, and described sponge gymnasium is mainly made of hardened road surface 1, glue layer 2 and waste rubber particle layer 3 from bottom to top; The surface of described waste rubber particle layer 3 is formed by electric heating iron plate Hard ironing layer 4.

[0021] The total thickness of the glue layer, the waste rubber particle layer and the ironing layer is 8-10mm.

[0022] The average rubber particle diameter of the waste rubber particle layer is 1-2 mm.

[0023] The hardened road surface 1 is formed by compacting mountain yellow mud.

[0024] During construction, first tamp the roadbed of the gymnasium, and then apply glue on the surface, then lay waste rubber particles with an average particle size of 1-2mm on the glue and compact them. After curing, the surface of the waste rubber particle layer Iron it with an electric heating iron plate to form a hard ironing layer.

[0025] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com