A handling and loading mechanism for improving arm stroke and driving force

A technology of driving force and actuator, which is applied in the direction of mechanically driven excavators/dredgers, etc., can solve the problems of insufficient driving force and lifting force, insufficient handling force, short loading stroke, etc., and achieve simple and compact structure and easy coordination of work , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

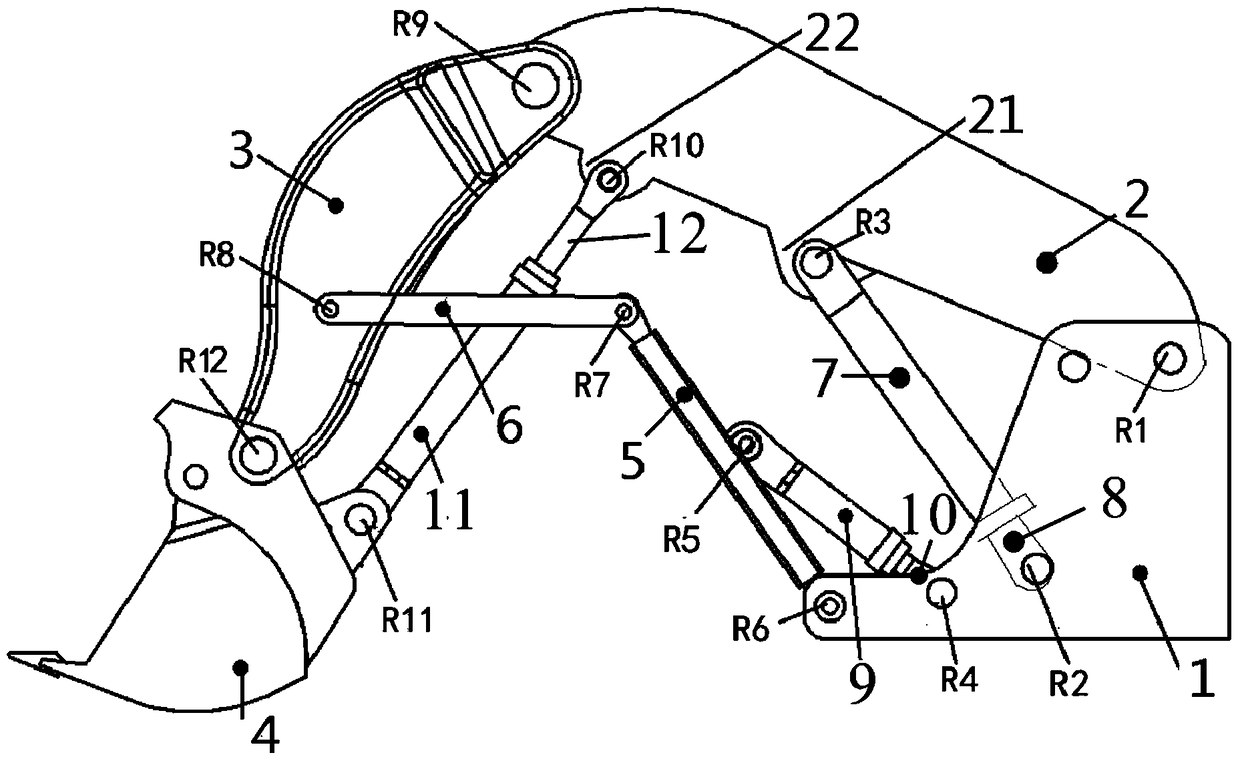

[0019] Embodiment 1: The present invention provides a transporting and loading mechanism for improving arm stroke and driving force, its structure is as follows figure 1 Shown is a schematic structural view of a preferred embodiment. The present invention comprises sequentially articulated frame 1, boom 2, stick 3, and terminal actuator 4; Hinged by hinge R9, the other end of the arm is hinged with the terminal actuator by hinge R12. The present invention is also provided with frame connecting rods 5 , arm connecting rods 6 , boom hydraulic cylinders 7 , arm hydraulic cylinders 9 and terminal actuator hydraulic cylinders 11 installed in pairs.

[0020] The boom 2 described in the present invention is symmetrically provided with a pair of upper hinged ears 22 and middle hinged ears 21 in the upper and middle parts of the side facing the terminal actuator respectively, and hinged holes are opened in the hinged ears.

[0021] The ends of the cylinder sleeves of the pair of boom...

Embodiment 2

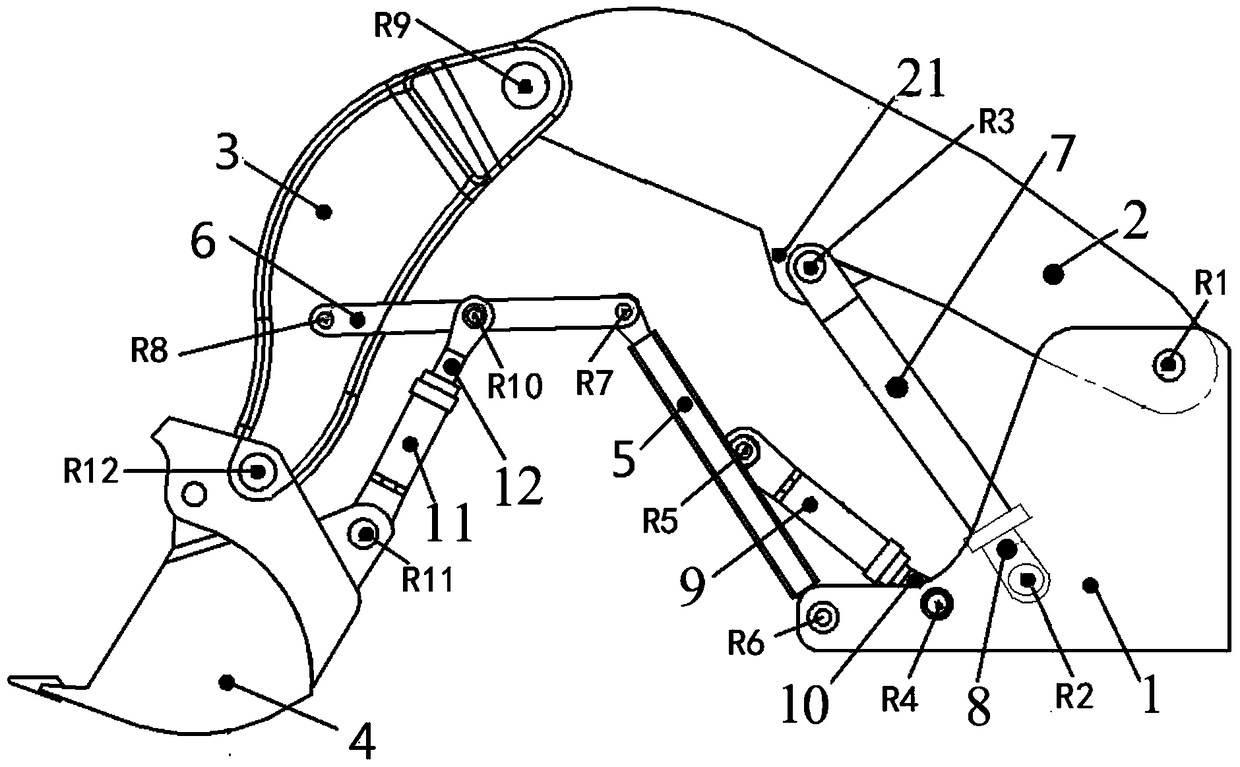

[0024] Embodiment 2: The present invention provides a transporting and loading mechanism for improving arm stroke and driving force, its structure is as follows figure 2 As shown, the transport loader of this embodiment is used as a mine-used front shovel hydraulic excavator, and its structure is basically the same as that of Embodiment 1. The difference is that the boom 2 is only symmetrically provided with a pair of middle articulation ears 21 in the middle. One end of the hydraulic cylinder barrel 11 of the terminal actuator is hinged with the terminal actuator 4 through the hinge R11, and the end of the piston rod 12 of the hydraulic cylinder of the terminal actuator is hinged at the middle part of the arm connecting rod 6 through the hinge R10, that is, the second A hinged way. In the handling loader of this embodiment, the end of the piston rod 12 of the hydraulic cylinder of the terminal actuator is hinged to the middle part of the arm connecting rod 6, and a forward r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com