Direct-heating waste heat recovery system of centrifugal type and oil-free screw type compressors

A waste heat recovery system and waste heat recovery technology, applied in lighting and heating equipment, heat exchanger types, indirect heat exchangers, etc., can solve the problem of shortened service life of heat exchangers, inability to perform complete heat exchange, and reduced heat exchange efficiency, etc. problem, to achieve the effect of prolonging the service life, not easy to scale, sufficient and uniform heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

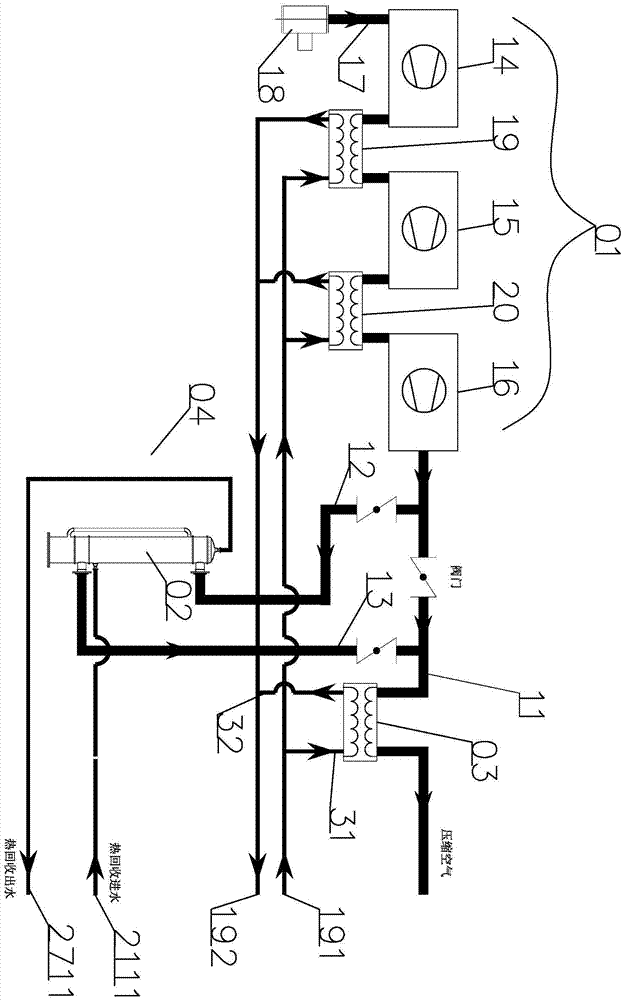

[0023] The direct heating type of embodiment 1 is that no secondary heat exchanger, internal circulation water pump and expansion tank are installed.

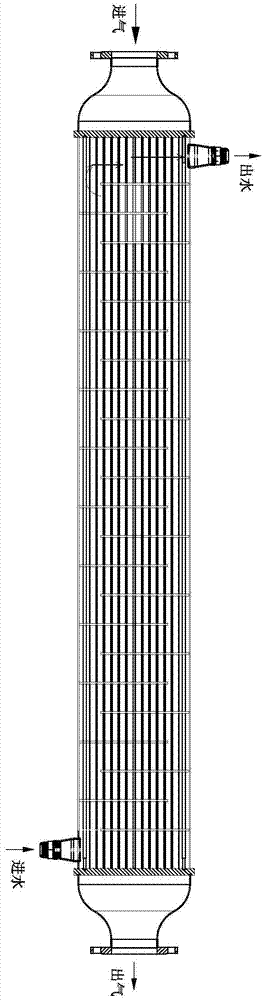

[0024] Such as figure 2As shown, the direct heat waste heat recovery system of centrifugal and oil-free screw air compressors includes air compressor 01, waste heat recovery device 02 connected to the pipe body of air compressor The stage cooler 03, and the heat recovery water pipe body 04 connected with the waste heat recovery device 02 pipe body. The waste heat recovery device 02 is a vertically installed waste heat recovery device 02 . The waste heat recovery device 02 includes a vertical tube shell main body 21, a plurality of equal-length inner heat transfer tubes 22 are arranged inside the vertical tube shell main body 21, and the inner heat transfer tubes 22 are jacketed with a length corresponding to the length of the inner heat transfer tubes 22. The outer heat transfer sleeve 23, the first tube plate 24 for fixing ...

Embodiment 2 2

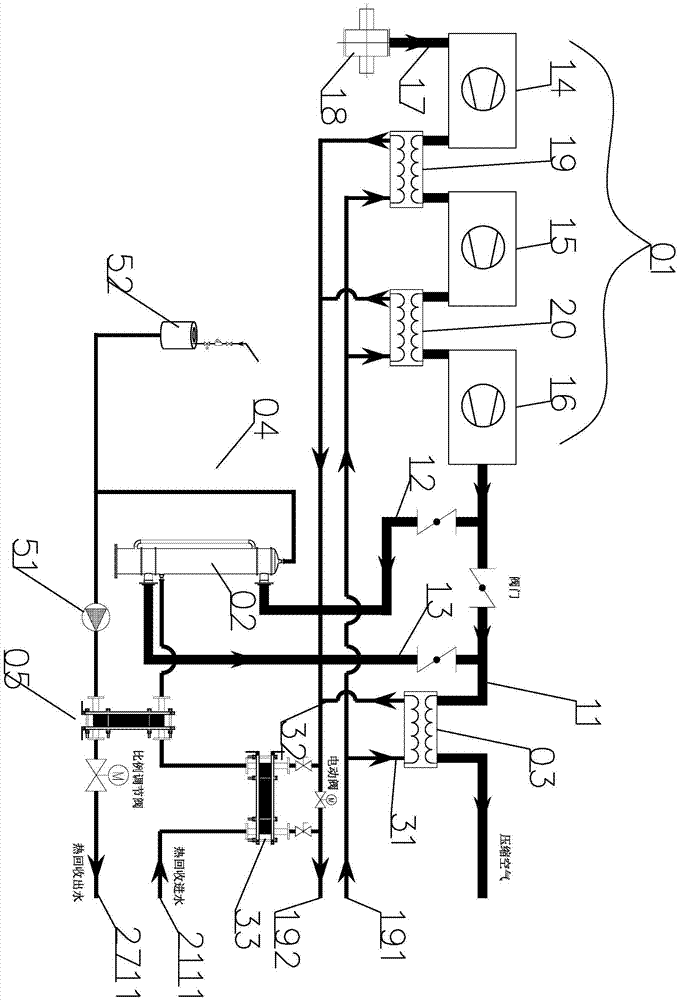

[0026] Embodiment 2 The secondary exchange type is that a secondary heat exchanger, an internal circulation water pump and an expansion tank are installed.

[0027] Such as image 3 As shown, the direct heat waste heat recovery system of centrifugal and oil-free screw air compressors includes air compressor 01, waste heat recovery device 02 connected to the pipe body of air compressor The stage cooler 03, and the heat recovery water pipe body 04 connected with the waste heat recovery device 02 pipe body. The waste heat recovery device 02 is a vertically installed waste heat recovery device 02 . The waste heat recovery device 02 includes a vertical tube shell main body 21, a plurality of equal-length inner heat transfer tubes 22 are arranged inside the vertical tube shell main body 21, and the inner heat transfer tubes 22 are jacketed with a length corresponding to the length of the inner heat transfer tubes 22. The outer heat transfer sleeve 23, the first tube plate 24 for f...

Embodiment 3

[0029] Embodiment 3 The embodiment of centrifugal air compressor:

[0030] According to the same principle, the waste heat of the high-temperature compressed gas generated at each stage of the compressor can be recovered. The high-temperature compressed gas enters the air storage chamber 25 from the inlet pipe port 251, and then the compressed air flows from the interlayer between the inner heat transfer tube 22 and the outer heat transfer sleeve 23 to the outlet air storage chamber 26 at the other end. The compressed air is discharged from the outlet pipe port 261 .

[0031]If the direct heating structure is adopted, after the water enters through the water inlet pipe 211, it directly exchanges heat with the waste heat recovery device 03 . In this way, the hot water enters the inside of the vertical shell main body 21 and exchanges heat with the outer surface of the outer heat transfer sleeve 23 . When the hot water rises to the external connecting pipe 272 on the main body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com