Surface form error measurement method for shallow aspheric surface

A technology of surface error and measurement method, which is applied to measurement devices, instruments, optical devices, etc., can solve the problems of large error and high cost, and achieve the effect of small error, low cost and small return error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further explained with a specific embodiment below, but it is not intended to limit the protection scope of the present invention.

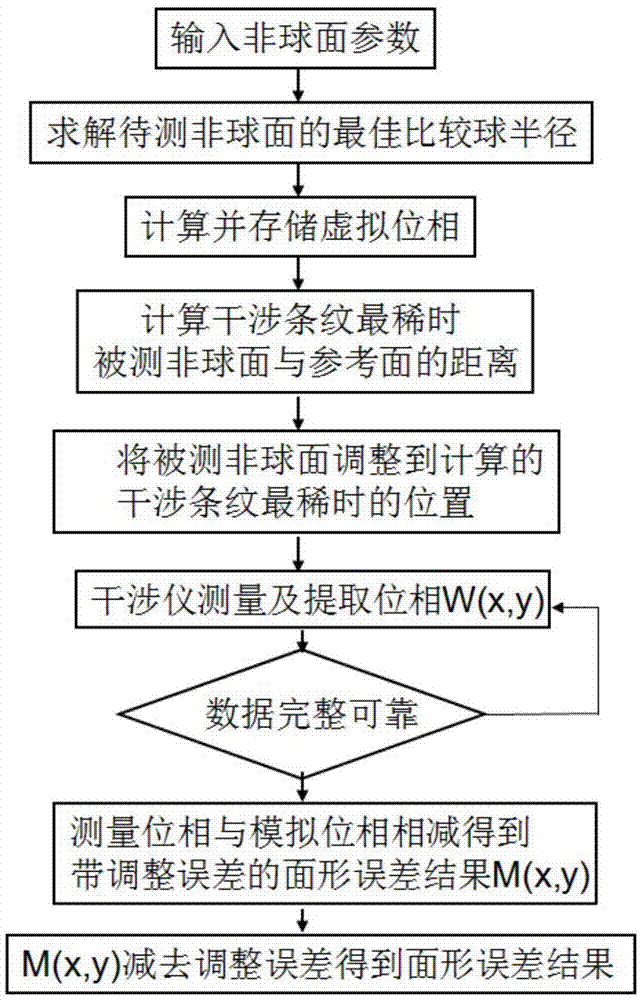

[0038] In order to solve the problems of large errors and high costs in the measurement of aspheric surfaces in the past, this embodiment provides a surface error measurement method for shallow aspheric surfaces.

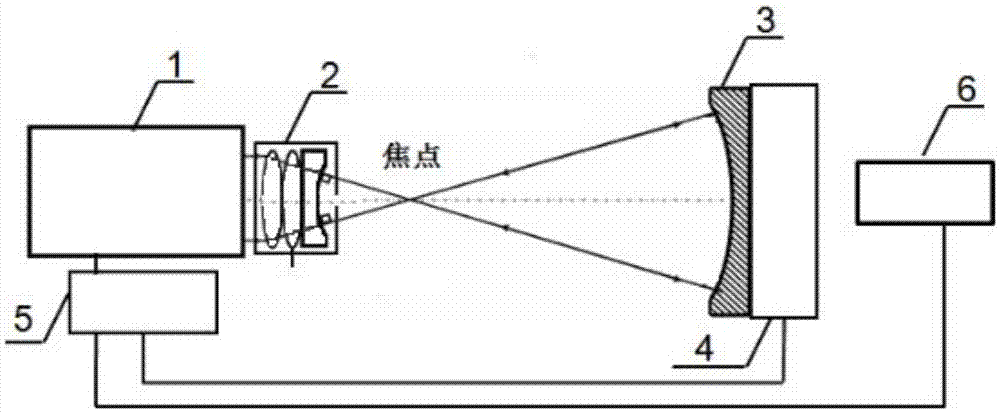

[0039] see figure 1 The measurement system used in the surface shape error measurement method for shallow aspheric surfaces is composed of an interferometer 1, a standard transmission spherical mirror 2, a measured aspheric surface 3, an adjustment mechanism 4, a computer 5 and a mirror positioner 6. The measured aspheric surface 3 is installed on the adjusting mechanism 4, and the adjusting mechanism 4 is used to adjust the inclination, eccentricity and defocus of the measured aspheric surface 3. The mirror locator 6 is used to detect the distance between the reference surface of the standard tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com