Load simulator based on series-parallel mechanism

A technology of load simulator and hybrid mechanism, which is applied in the testing of machine/structural components, testing of mechanical components, instruments, etc., to achieve the effects of strong versatility, reduced return error, and reduced redundant degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

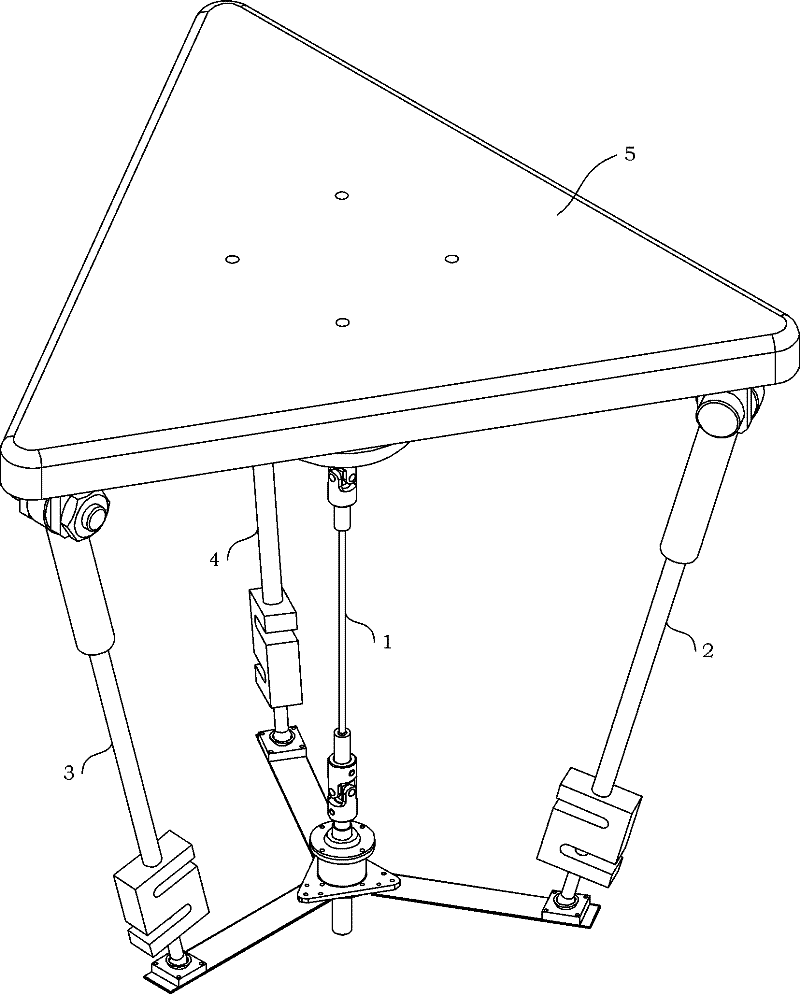

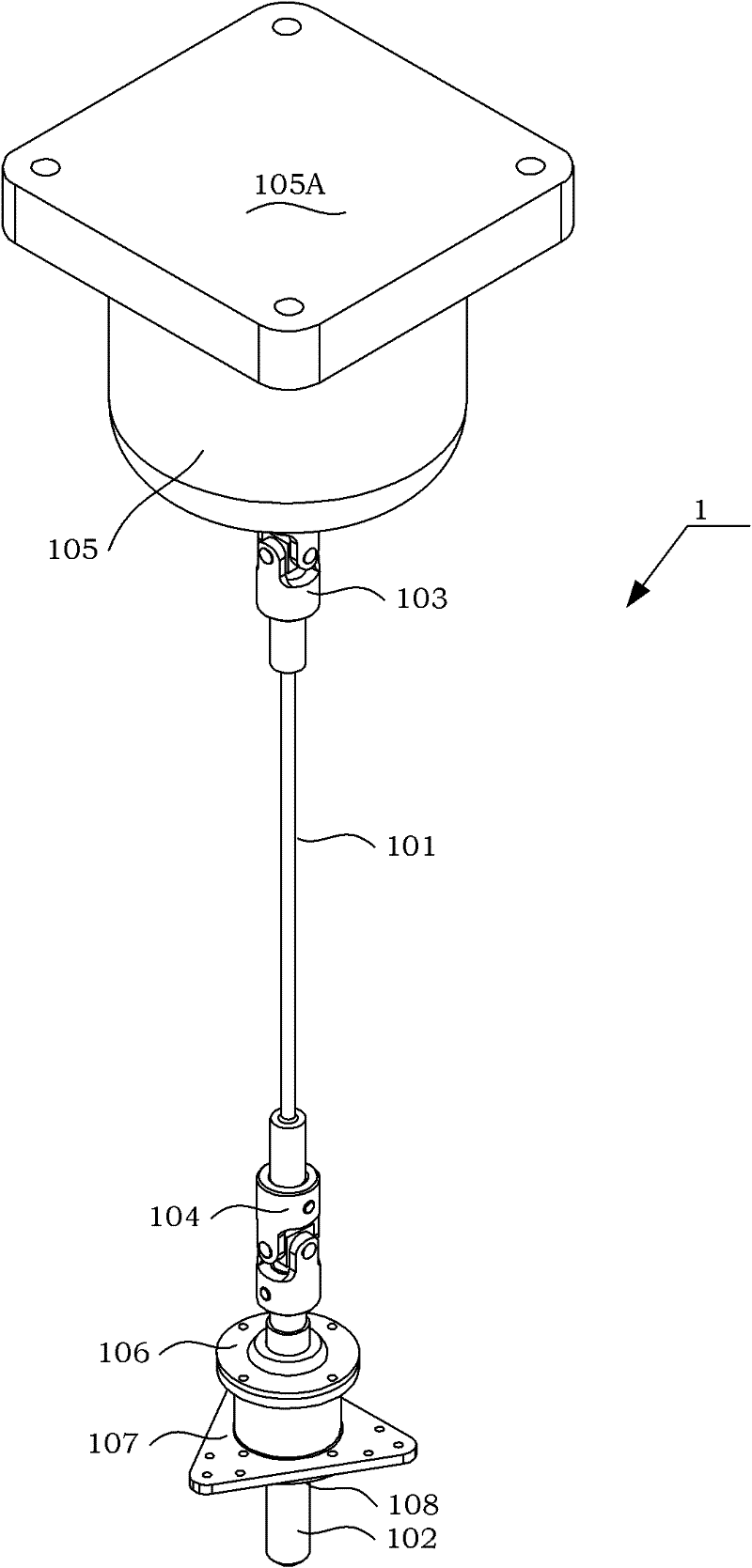

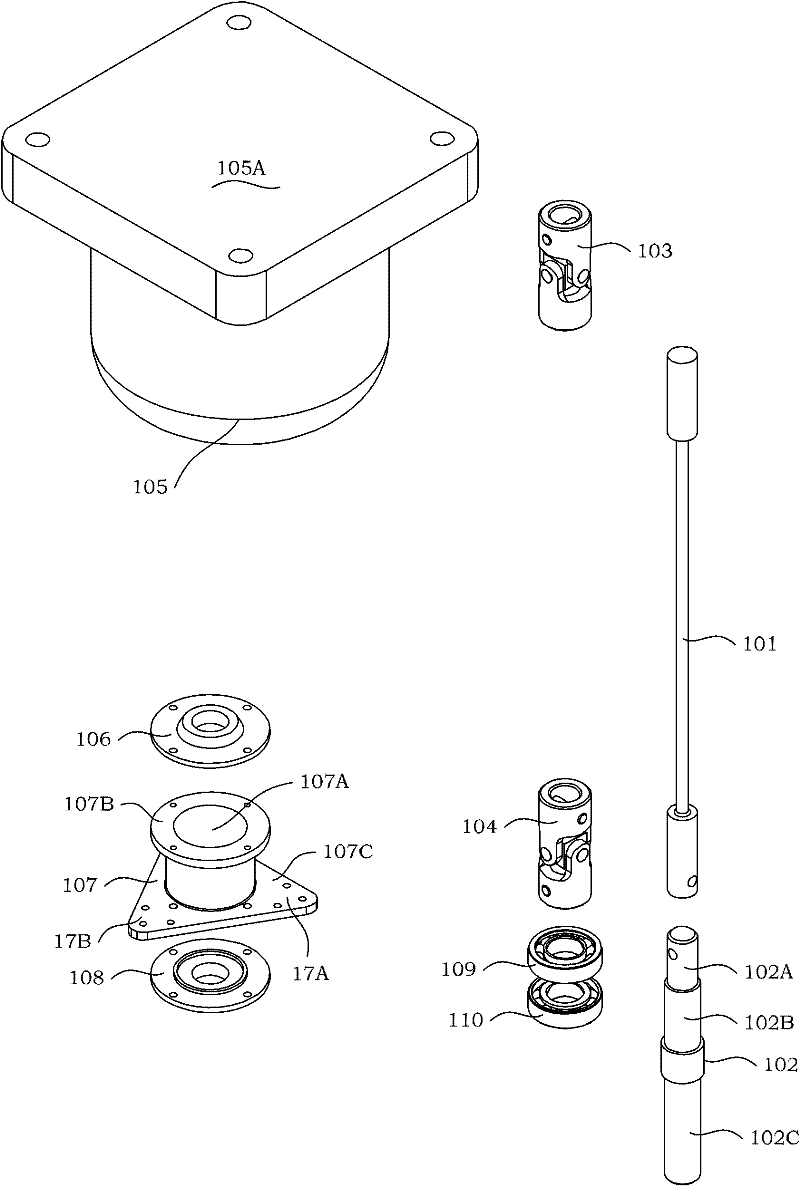

[0023] The basic idea of the load simulator based on the hybrid mechanism of the present invention is: 3-RPS (3-Revolute-Prismatic-Spherical, translated as 3-rotating pair-moving pair-ball pair) mechanism is a zero-torsion mechanism, and 3 - The RPS parallel mechanism has three degrees of freedom to rotate around two vertical axes in the upper platform and move along the vertical axis of the upper platform plane. In the case of fretting, the movement of the parallel mechanism can be used to apply axial pulling or pushing force to the shaft of the loaded part; and the rotation of the parallel mechanism can be used to apply a bending moment to the shaft of the loaded part. Axial force loading and bending moment loading can be decoupled from each other, and can be applied to the shaft of the loaded part individually or in combination. The 3-RPS mechanism and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com