Continuous and accurate variable loading device

A loading device and load technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of unstable load changes and inability to accurately control the load, and achieve the effect of increasing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

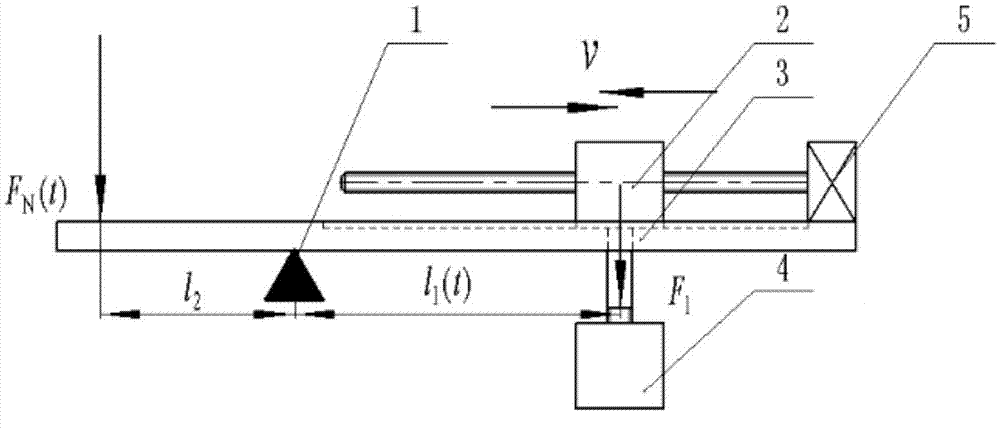

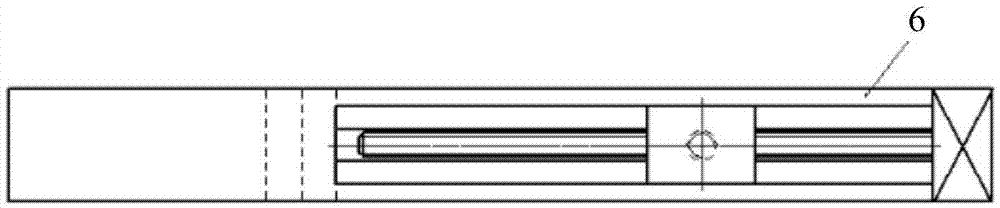

Method used

Image

Examples

Embodiment 2

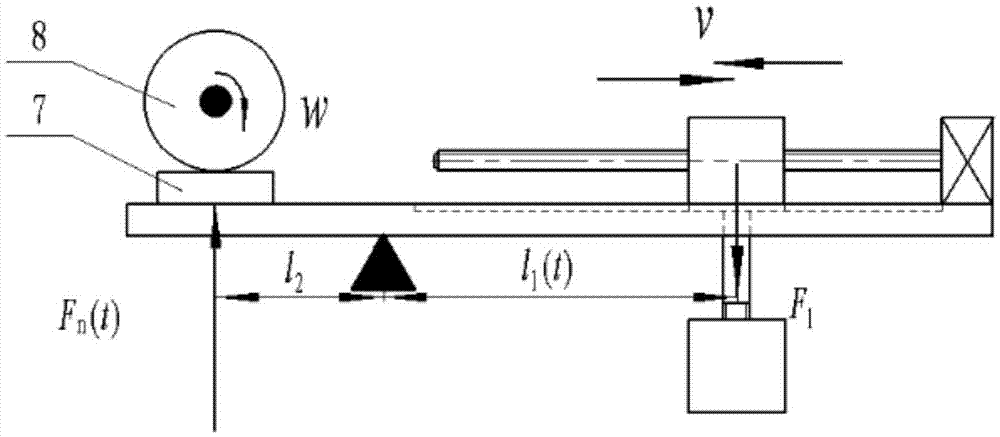

[0037] Case 2 as Figure 4 As shown, in this case, the device of the present invention is applied to the test of fatigue mechanical properties of bearings on high-speed railways, advanced automobiles or fighter jets, and the corresponding load spectrum can be easily drawn.

[0038] In this case, the bearing 10 is fixed on the bearing seat 11, and the slider 12 with the collar can move linearly on the shaft 9 through the collar. A linear motor is used to control the slider to move on the shaft, and further control the magnitude of the torque applied to the support point. Through this continuous and precise change of the torque, a continuous and precise change of the value of the loading force is achieved.

[0039] By continuously and accurately changing the loading force, the mechanical properties of the bearing under continuous loading force are tested, and the load spectrum is listed. Thereby, there is a more accurate understanding of the performance of the bearing, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com