Repair tracking control method for bad products

A tracking control and poor technology, applied in the direction of instruments, etc., can solve problems such as the inability of enterprise managers to improve and trace in time, reduce the yield rate of production lines, and affect the quality of the company, so as to reduce the scrap rate of products, ensure the launch point, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

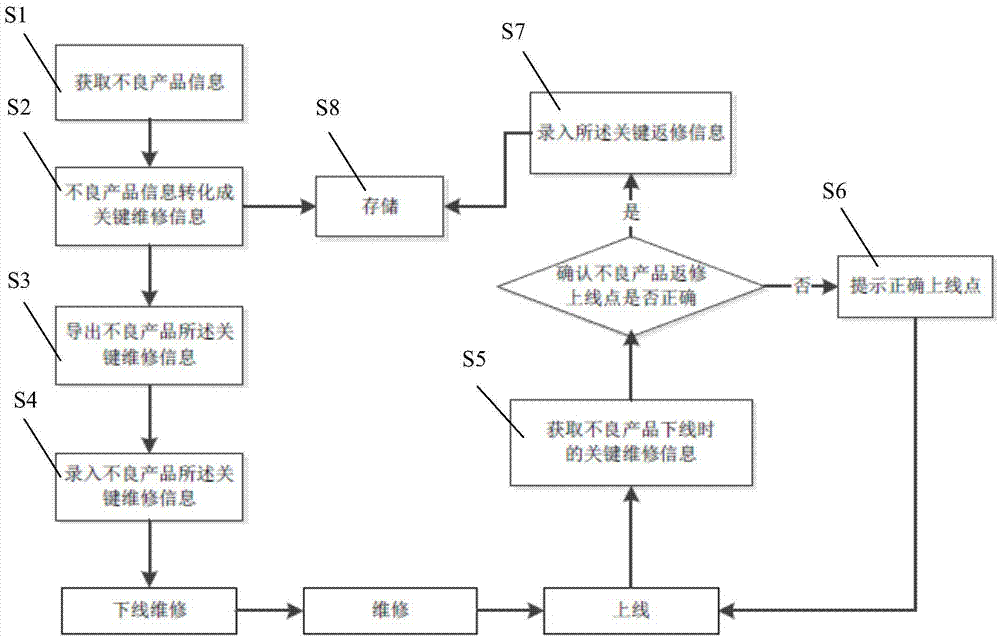

[0014] see figure 1 As shown, the figure discloses the implementation process of the defective product repair tracking control method provided by the embodiment of the present invention. For the convenience of description, only the part related to the embodiment of the present invention is disclosed, and the details are as follows:

[0015] In step S1, obtain bad product information;

[0016] Among them, in the production line, each station is equipped with an RFID (radio frequency identification, radio frequency identification) information acquisition function device. When the RFID information acquisition function device acquires the product, it finds that there is product failure (unqualified or defective) information, Then the bad product information is transmitted to C2IMS (Intelligent Manufacturing Information System), and the S2 step is executed. If no bad information is found, the product is qualified and flows into the next station for operation.

[0017] In step S2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com