Two-way pre-stress clamping device used for spine implant and installing method thereof

A clamping device, lateral prestressing technology, applied in spinal implants, joint implants, joint implants, etc., can solve the problems of vertebral tension, compression force, shear force and torque that cannot be effectively transmitted , to reduce the risk of slippage and improve the effect of effective transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with drawings and embodiments.

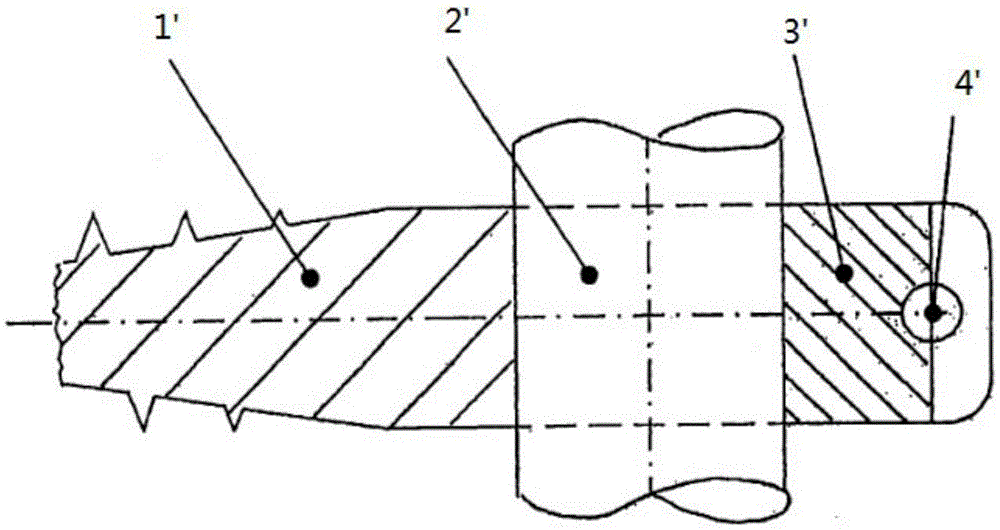

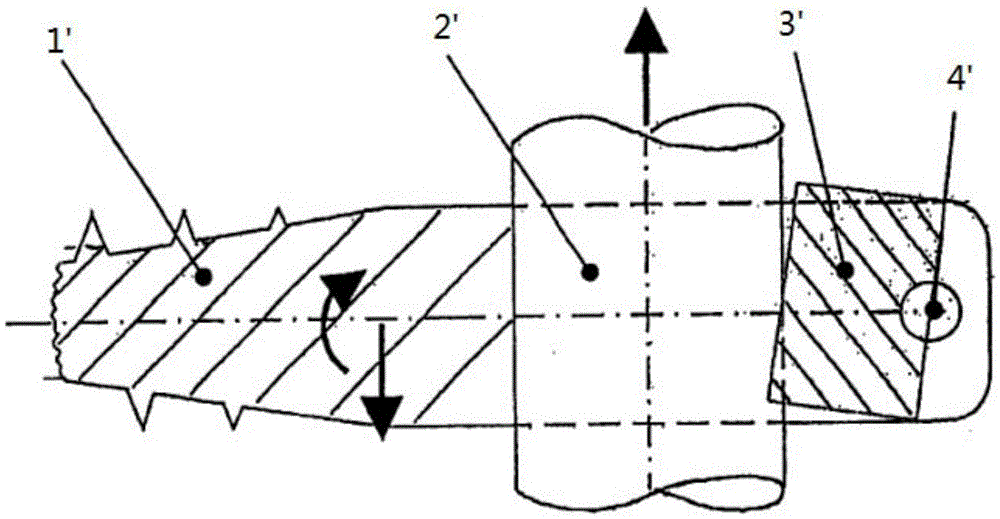

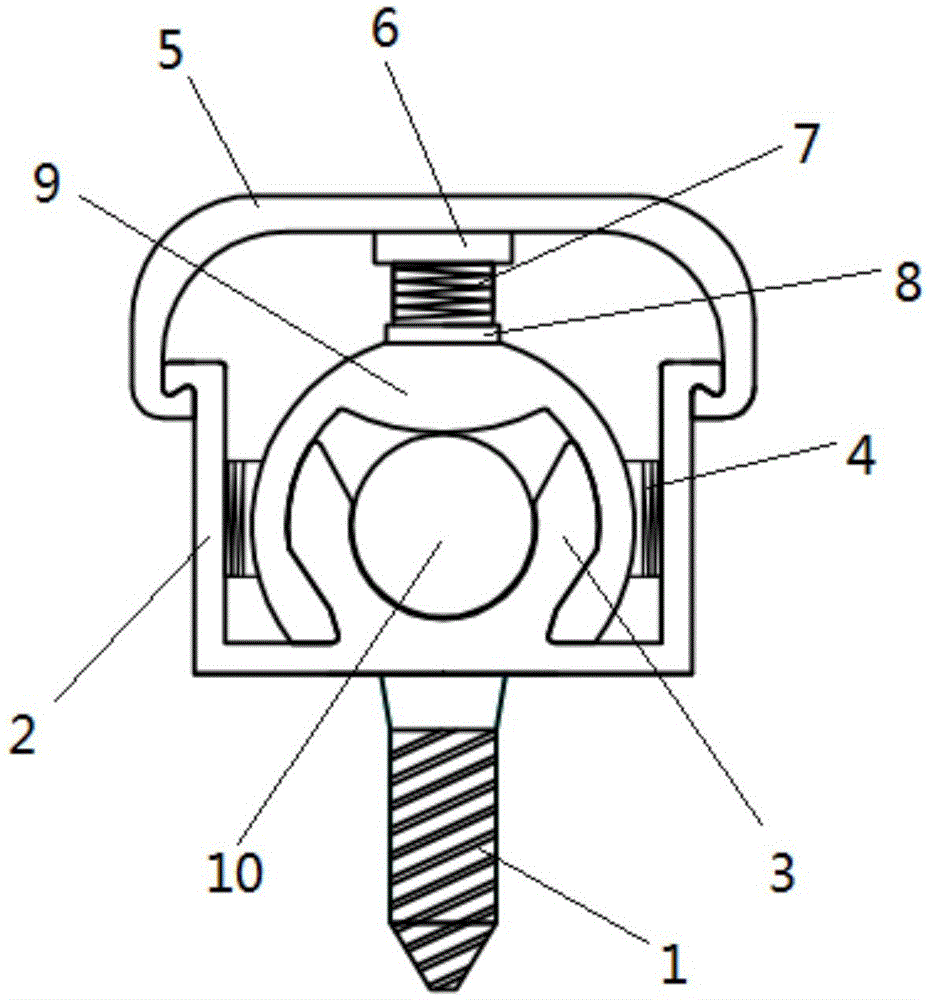

[0058] Such as Figure 1-3 As shown, a bidirectional prestressed clamping device for spinal implants includes a screw 1 , a U-shaped piece 2 , a support 3 , a cover plate 5 , a prestressed piece and a clamping piece 9 .

[0059] The prestressing elements include one vertical prestressing element 7 and two transverse prestressing elements 4 .

[0060] The U-shaped piece 2 includes a U-shaped piece bottom plate 21 and two U-shaped piece side walls 22 extending upward from the U-shaped piece bottom plate 21 . The bottoms of the two U-shaped side walls 22 are respectively connected to the corresponding ends of the U-shaped bottom plate 21; The inner surfaces of the side walls 22 of the U-shaped member are respectively provided with transverse prestressing members 4 protruding inward.

[0061]The bottom surface of the U-shaped piece bottom plate 21 is fixed with the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com