Dispensing table for rear axle assembly of electric vehicle

A technology for electric vehicles and rear axles, applied in assembly machines, vehicle parts, transportation and packaging, etc., can solve the problems of motor sub-assembly weight, long processing cycle, different positioning heights, etc., to ensure assembly quality and scope of application Broad, friction-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

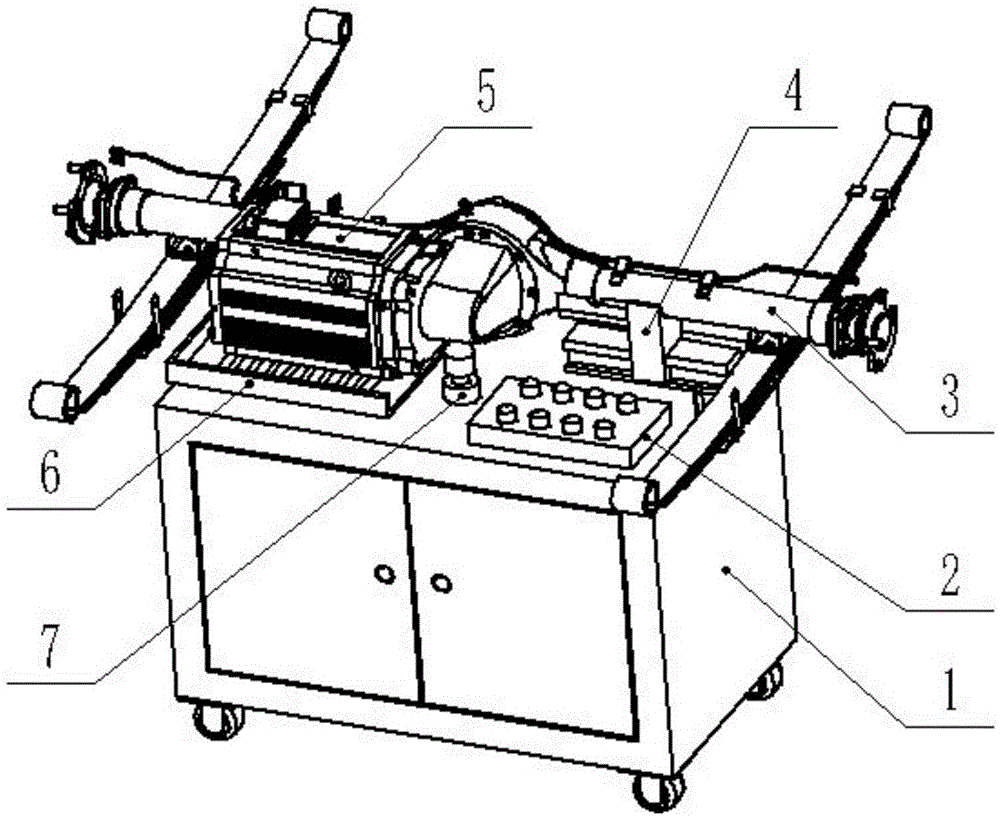

[0020] see figure 1 , the structure of the preferred embodiment of the present invention includes a main body platform 1, a mobile support frame 4 and a lifting support column 7; the mobile support frame includes a slide block and a slide rail, the slide rail is fixed on the main body platform, and the slide block can Move horizontally in the rail; the bottom of the lifting support column 7 is fixed on the main platform 1, and the height of the top of the lifting support column can be adjusted. The position and height of the rear axle sub-assembly 3 can be adjusted arbitrarily through the cooperative use of the movable support frame 4 and the lift-type support column 7, which facilitates its installation with the motor sub-assembly 5, and has a wide range of applications and strong versatility.

[0021] Preferably, the sub-packaging station further includes a motor support plate 6 fixed on the main body platform 1 , and a rolling device (rolling bearing, ball or roller, etc.) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com