Tooling for assembling a reinforced mesh cage

A steel mesh and assembly device technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low efficiency, uneven steel mesh, affecting production efficiency, etc., to reduce production costs and improve assembly efficiency. , The effect of improving assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

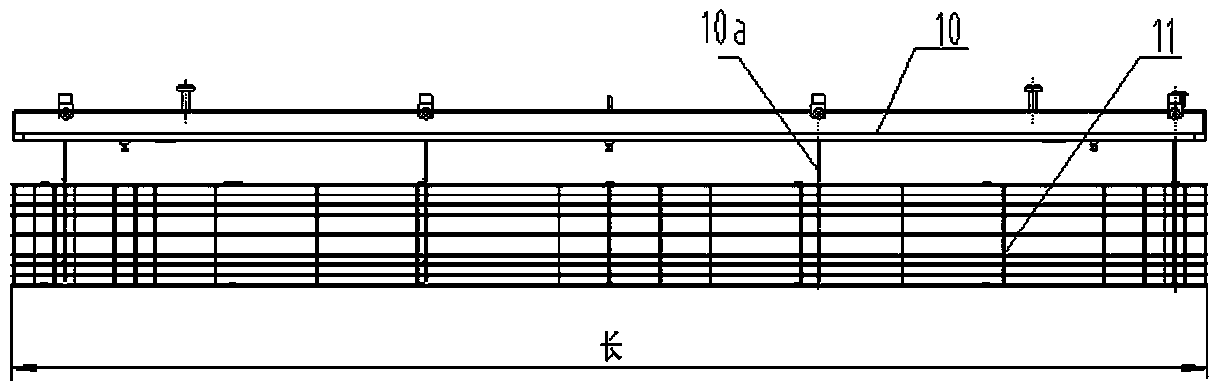

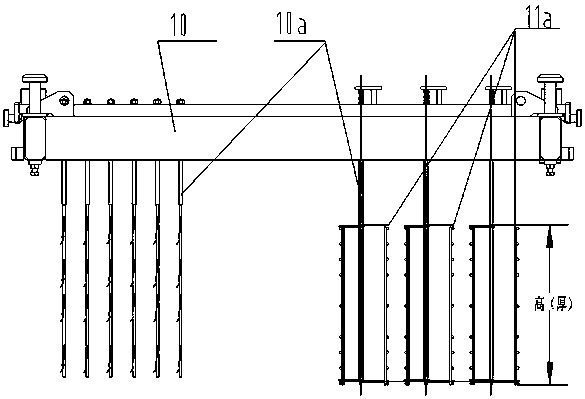

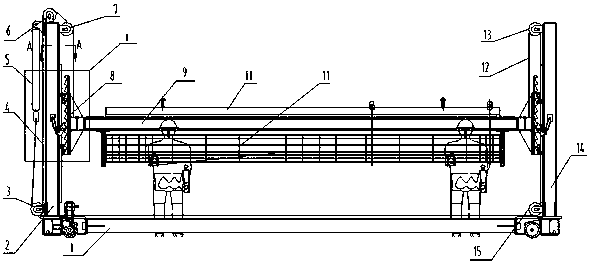

[0032] As shown in the figure, a tooling for assembling a reinforced mesh cage includes a support frame 1, a first column 2 and a second column 14 are arranged on the support frame 1, and a reinforced mesh cage assembly device 9 is provided between the two columns. , also be provided with on two uprights and be used for lifting the lifting mechanism that reinforced mesh cage assembling device 9 is carried out.

[0033] In this embodiment, the support frame 1 includes two bases 101, which are fixedly connected together by a connecting piece 102, and the first column 2 and the second column 14 are respectively fixed on the upper surfaces of the two bases.

[0034] In this embodiment, the lifting mechanism includes a lifting hydraulic cylinder 5 with one end hinged to the first column. The piston rod extension end of the lifting hydraulic cylinder 5 is connected with the first steel wire rope 4 and the second steel wire rope 12, and the first steel wire rope 4 is bypassed. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com