Assembly table for parts of engine oil cooler

An oil cooler and component assembly technology, which is applied in assembly machines, workpiece clamping devices, workbenches, etc., can solve problems such as easy dropping of workpieces, and achieve the effect of improving assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

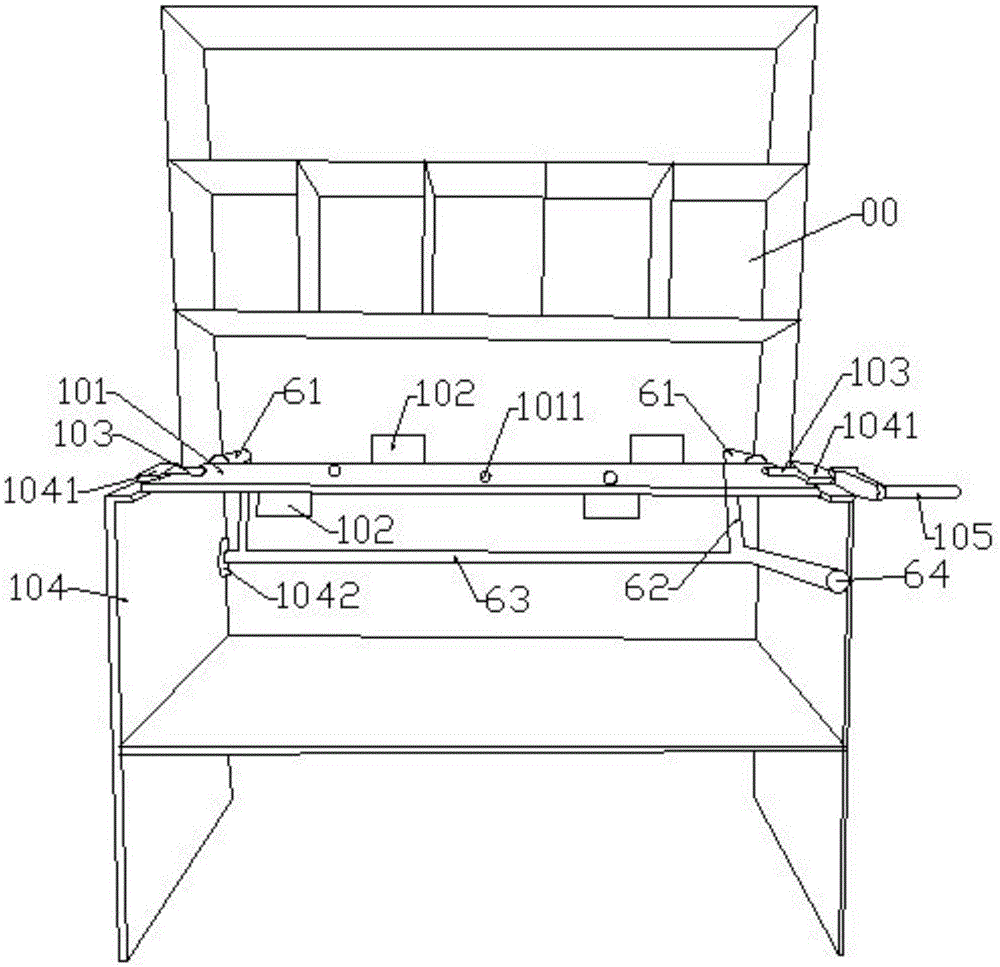

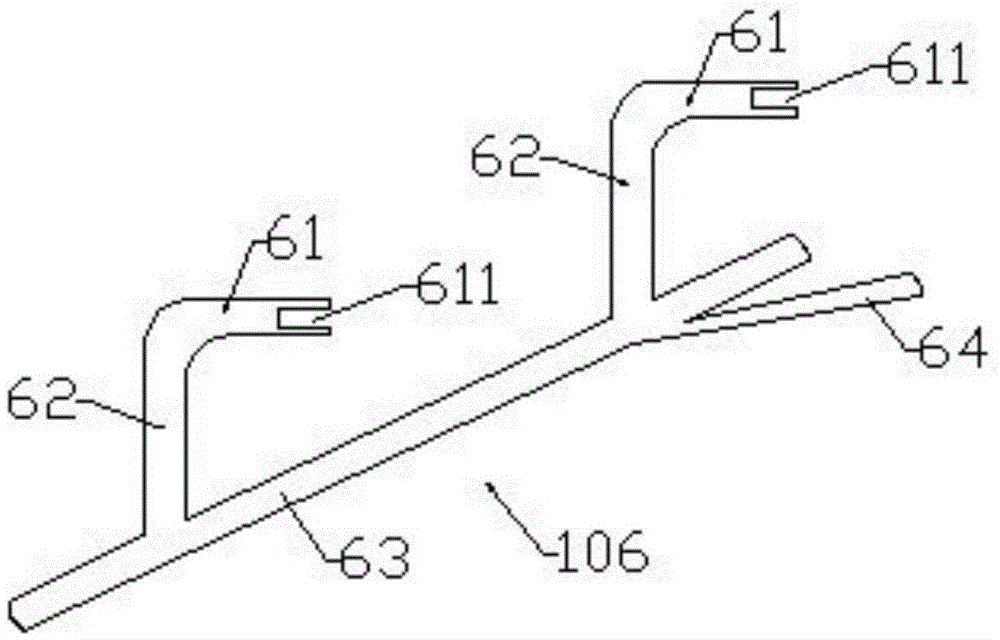

[0022] figure 1 It is a schematic structural diagram of the oil cooler component assembly platform provided by Embodiment 1 of the present invention; figure 2 It is a structural schematic diagram of the fixing mechanism in the oil cooler component assembly platform provided by Embodiment 1 of the present invention; as shown in the figure, the engine oil cooler component assembly platform provided by Embodiment 1 of the present invention includes: an overturning platform for placing workpieces Plate 101, the top and bottom of the turning platen 101 are provided with a pressing mechanism 102 for pressing the workpiece, and the middle position of both ends of the turning platen 101 is integrally formed with a turning shaft 103, and the turning shaft 103 is placed on the assembly In the turning shaft 1041 hole of the frame 104, one end of the turning shaft 103 is integrally formed with a rocker 105, and the assembly frame 104 is also provided with a fixing mechanism 106 for fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com