Crane wheel bearing pressing-in device

A technology for wheel bearings and cranes, used in hand-held tools, manufacturing tools, etc., can solve the problems of difficult quality assurance, economic losses of enterprises, slow assembly speed, etc., and achieve the effect of improving production efficiency and quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

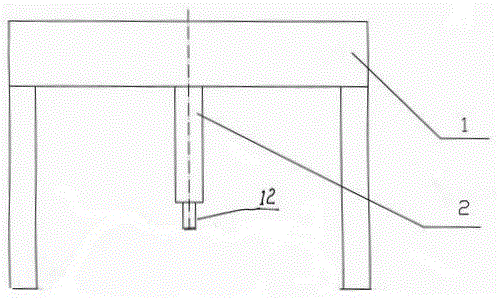

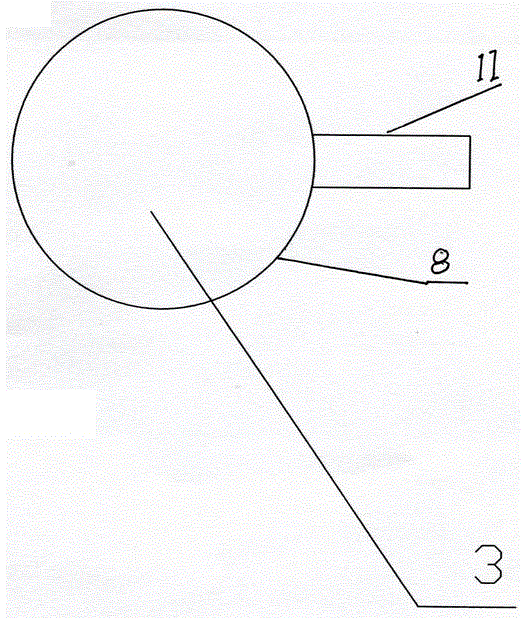

[0008] The embodiment is described in detail in conjunction with the above drawings. This technical solution is composed of a frame, a hydraulic device, a positioning device and a backing plate. The frame 1 is composed of an upper beam and a side beam. A disk capable of carrying a hydraulic device is fixed by bolts, and a positioning device 7 and a backing plate of a movable part are fixed on the base surface in the portal frame.

[0009] Described hydraulic device 2 is made of hydraulic cylinder, hydraulic rod 14 and cylindrical pressure head, further says: the hydraulic oil pipe that can control the work of hydraulic cylinder is connected on the hydraulic cylinder, and hydraulic oil pipe is connected with pressure station, and the rod wall of hydraulic rod A cylindrical pressure head is wrapped on the top, furthermore, the center of the cylindrical pressure head is drilled with a hole for assembling the hydraulic rod, and the two are interference fit.

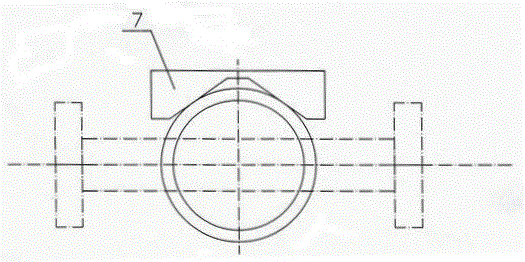

[0010] The positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com