Slitter for cutting sponge or standing cotton

A technology of upright cotton and slitting machine, applied in metal processing and other directions, can solve the problems of reducing production efficiency, incision hardening and agglomeration, blade fragmentation, etc., to avoid potential safety hazards, improve service life, and reduce friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

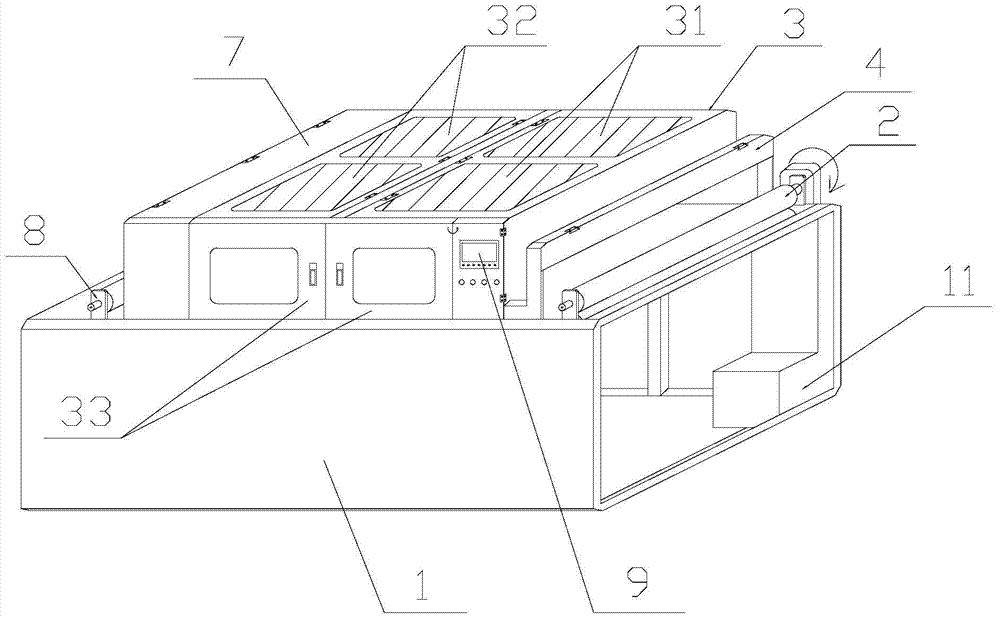

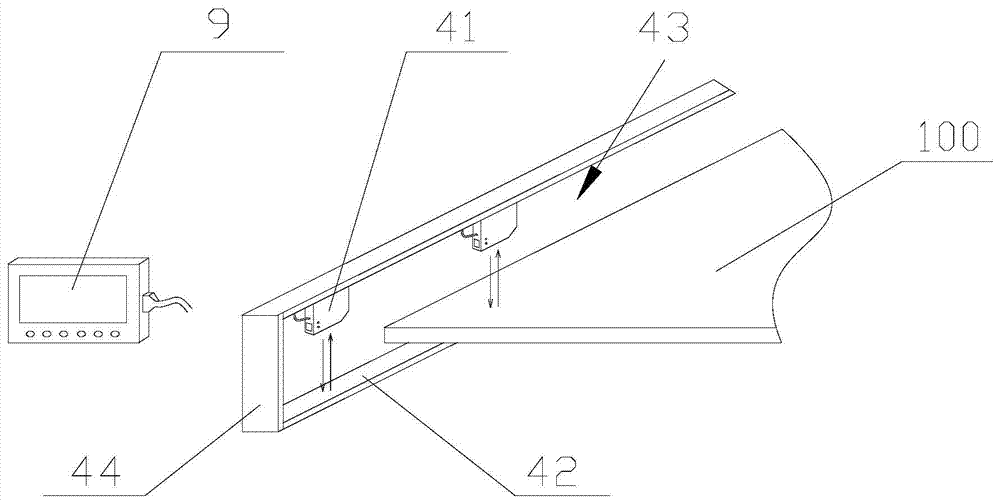

[0023] see Figures 1 to 6 , a cutting machine for cutting sponge or upright cotton, comprising a frame 1, on which a feed roller 2, a machine cover 3, a thickness testing device 4, a longitudinal cutting mechanism 5, a cross cutting mechanism 6, Elasticity testing device 7 and discharge roller 8. The machine cover 3 has a feed port and a discharge port, and the feed port and the discharge port are connected to form a channel for conveying sponge or upright cotton. The frame 1 is provided with a motor 11 for providing driving force. In the following embodiments, only the cutting sponge 100 is taken as an example to illustrate the present invention, and of course the present invention is also applicable to cutting upright cotton.

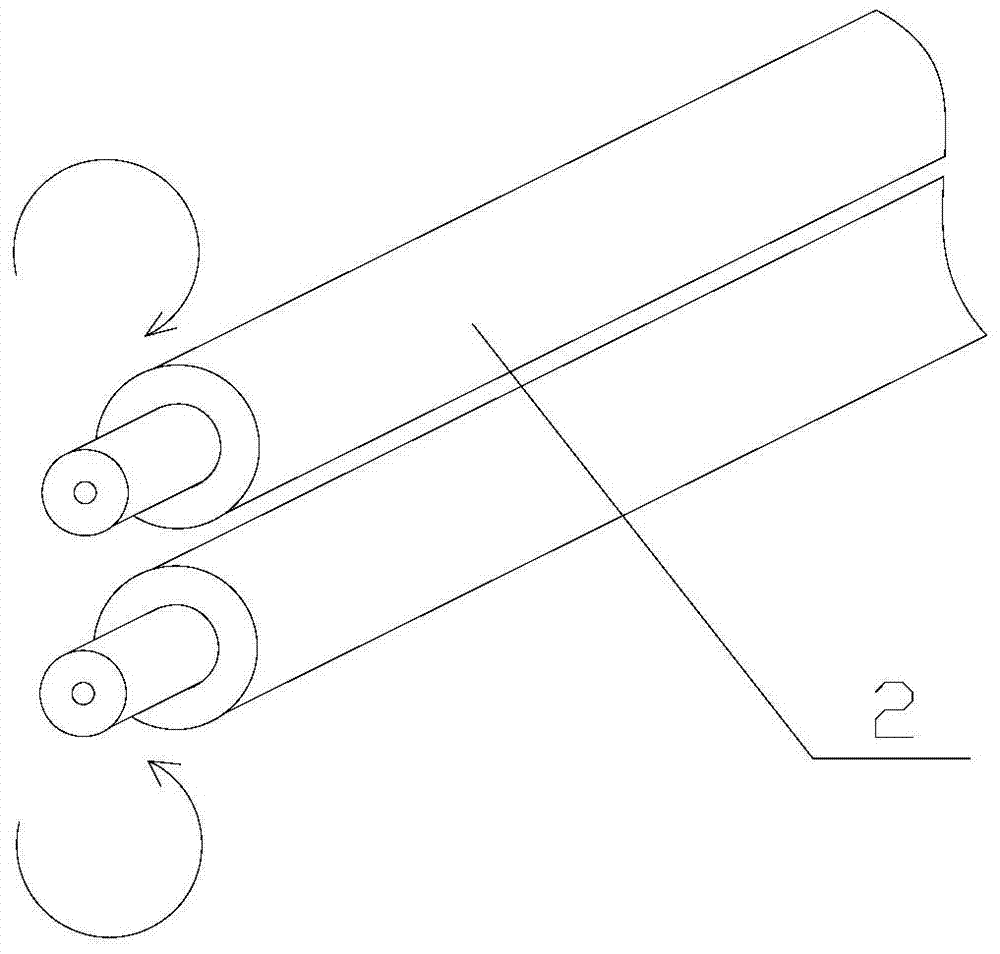

[0024] The feed roller 2 is set at the feed inlet, and the discharge roller 8 is arranged at the discharge out...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap