Novel polyethylene (PE) rotationally formed electrolytic cell liner structure

A technology of rotomolding and electrolytic tank, which is applied in the direction of electrolytic process, electrolytic components, plating tank, etc., can solve problems such as waste of labor intensity, leakage of material, difficulty in cleaning and discharging sewage, etc., and achieve high efficiency, reasonable structural design, timely and effective Effects of cleaning and blowdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

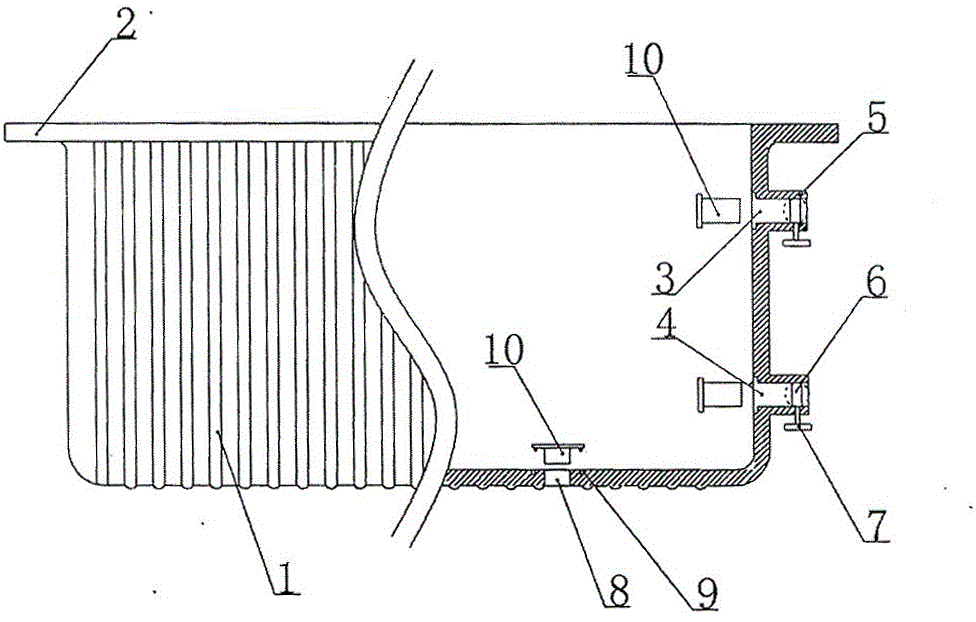

[0013] see figure 1 , the present invention is a new type of PE rotomolding-molded electrolytic cell liner structure, comprising an inner liner body 1 with an upper opening, the outer surface of the inner liner body 1 is in the shape of a corrugated strip, and the top of the inner liner body 1 is provided with flippers. Side 2, an overflow port 3 is provided on the upper part of one side of the inner tank body 1, a control mechanism is provided outside the overflow port 3, and a sewage outlet 4 is opened on the lower part of at least one side of the inner tank body 1 , the outside of the sewage outlet 4 is also provided with a control mechanism, and the control mechanism includes the connecting pipe 5 corresponding to the overflow port 3 or the sewage outlet 4, the inner diameter of the connecting pipe 5 and the inner diameter of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com