Methane production wet desulphurization elemental sulfur and filtering all-in-one equipment

A technology of wet desulfurization and elemental sulfur, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of elemental sulfur sinking, untimely, difficult cleaning of elemental sulfur, etc., and achieve the effect of reducing suspended sulfur and reducing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in further detail below in conjunction with the drawings and examples. The following examples are used to illustrate the present invention, but cannot be used to limit the scope of the present invention.

[0024] The "one embodiment" or "embodiment" referred to herein refers to a specific feature, structure, or characteristic that can be included in at least one implementation of the present invention. The appearances of "in one embodiment" in different places in this specification do not all refer to the same embodiment, nor are they separate or selectively mutually exclusive embodiments with other embodiments.

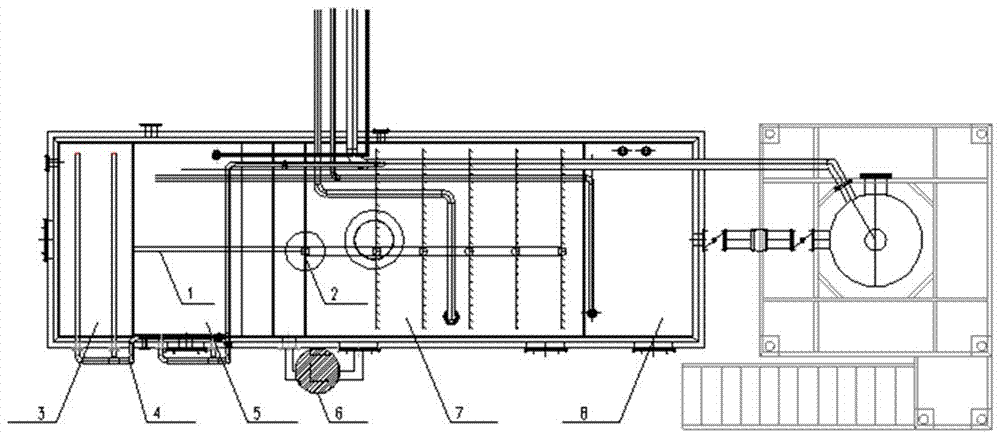

[0025] Such as figure 1 As shown, the integrated wet desulfurization element sulfur filtration equipment for biogas production of the present invention includes a sulfur foam overflow pipe 1, a sulfur foam scraper device 2, a sulfur foam tank 3, a foam increasing device 4, a mother liquor tank 5, and a sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com