Baffle plate type spandex defoaming apparatus

A spandex and defoaming technology, applied in the direction of spinning solution filtration, etc., can solve the problems of small defoaming area and incomplete defoaming, and achieve the effect of increasing the defoaming area and improving the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

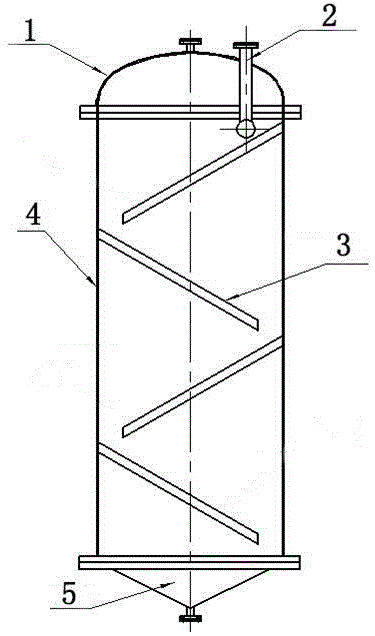

[0010] according to figure 1 As shown, the present invention is specifically a folding plate type spandex defoaming device, which includes an upper head 1, a cylinder body 4 and a lower head 5 from top to bottom, and the upper head is provided with a feed material extending to the inside of the cylinder body. Part 2, four baffles 3 are arranged in the cylinder and the baffles are located under the feeding part, one end of the baffle is connected to the inner wall of the cylinder, and the other end is an open end and is inclined to the lower part of the cylinder , the end of the uppermost baffle close to the feeding part is the connecting end, every two adjacent baffles are inclined in the opposite direction, there is only one gap at the open end between the baffle and the cylinder, and the other places are the same as The inner wall of the cylinder is connected.

[0011] The implementation of its function and effect is mainly that the equipment maintains a vacuum state of 8mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com