Method for denoising axial flow fan

A technology of axial flow fan and axial flow, which is applied in the direction of mechanical equipment, machine/engine, liquid fuel engine, etc., can solve the problems of device vibration, noise increase, equipment shaking, etc., and achieve reduction of collision, noise reduction, shock absorption noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

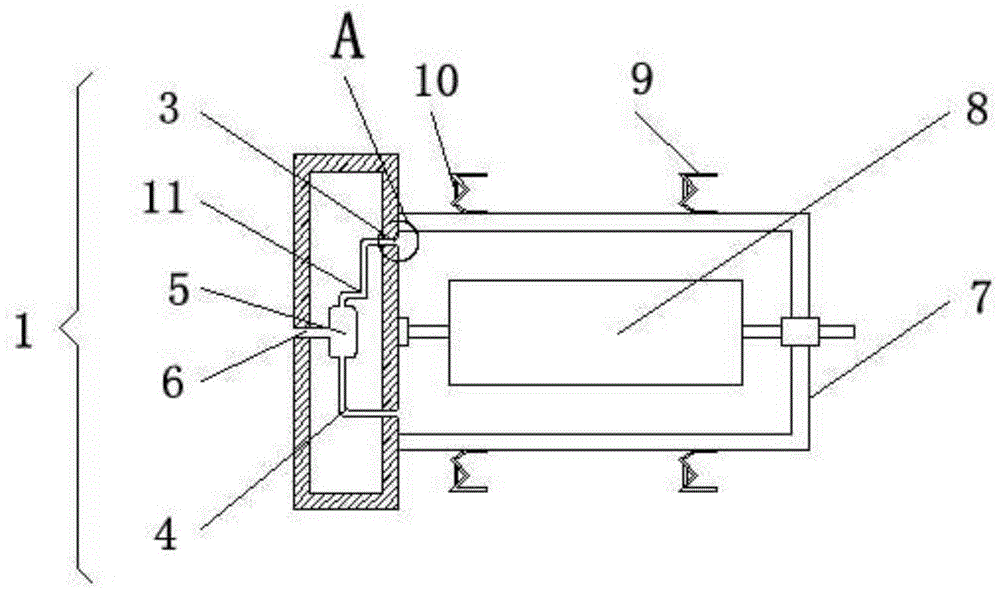

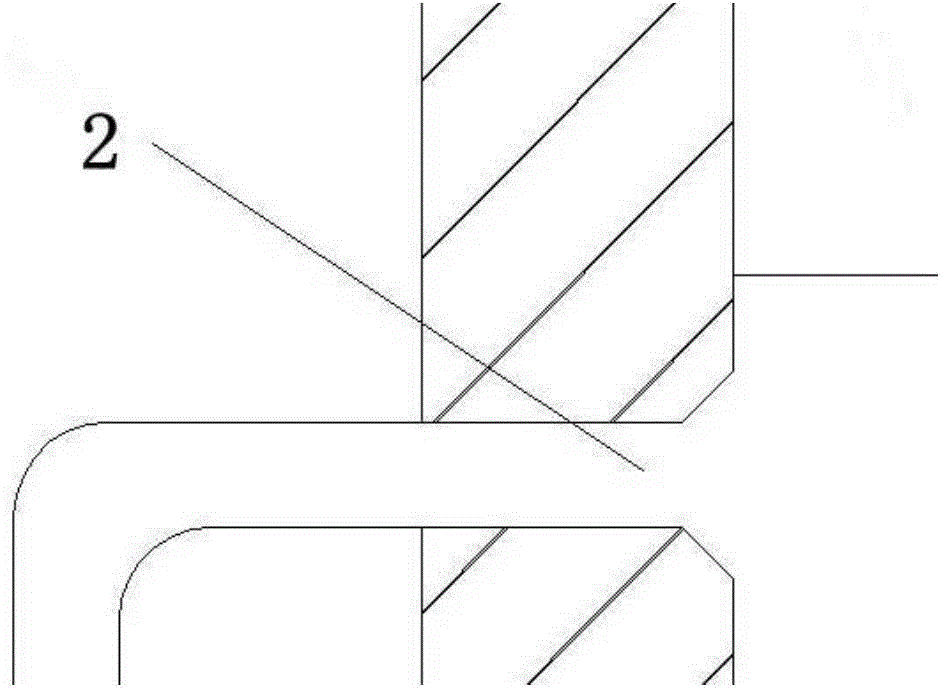

[0018] Such as Figure 1 to Figure 2 As shown, the present invention includes a sound-absorbing bottom cover 1, a stator 7, a rotor 8, and an "M" type bracket 9 including a rubber damping rod 10; 5 and the sound pipe 6, one end of the first 3 and second 4 of the silencing tube is connected to the upper and lower ends of the silencing chamber 5, and the other end is connected to the outer wall on the right side of the silencing bottom cover 1, this end A sound inlet 2 is arranged at the junction, and the sound inlet 2 is trumpet-shaped. The left side of the sound-absorbing bottom cover 1 is connected to the left outer wall of the sound-absorbing chamber 5 through the sound-out pipe 6 . The surroundings of the anechoic chamber 5 are rounded corners, and the corners of the anechoic pipe one 3 and the anechoic pipe two 4 are curved pipes 11; the anechoic bottom cover 1 is arranged on the left side of the stator 7 and integrally formed therewith; The rotor 8 is arranged inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com