Baffle valve device

A baffle valve and servo technology, applied in the direction of valve device, valve operation/release device, lift valve, etc., can solve the problems that it is difficult to realize fast opening and slow closing, complicated use of electromagnetic reversing valve, etc., and achieve rapid opening, Maintain the effect of long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

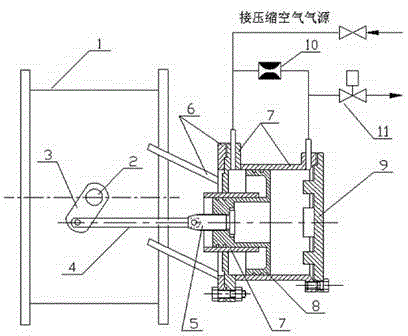

[0009] Referring to the accompanying drawings, a baffle valve device is mainly composed of a pneumatic servo and a connecting rod crank mechanism. In addition to the circular ring on the side force surface, add the circular area of the inner cylinder liner perpendicular to the axis of the cylinder liner. The area of the circular ring is equal to the circular cross-sectional area of the inner cylinder liner. The force-bearing area on the right side of the piston is the force on the left side. Twice the area; 2 or 4 stoppers are welded on the base plate of the round end cover of the servo cylinder; the intake air of the two chambers of the servo cylinder is the same air source, and the intake air of the right chamber enters through the throttling element; on the right side of the servo cylinder The side air inlet is connected with a discharge pipeline, and a normally closed solenoid valve is installed on the pipeline.

[0010] The driving mechanism for opening and closing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com