Pipe-threading robot for pipeline

A technology of robots and pipe penetration, which is applied in the field of robots and can solve problems such as danger, heavy work, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

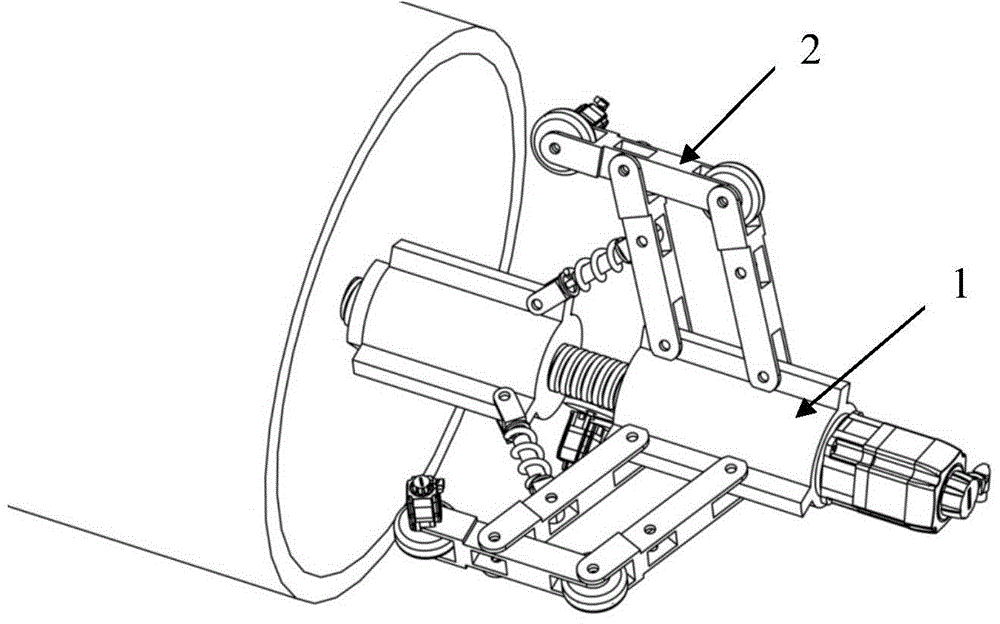

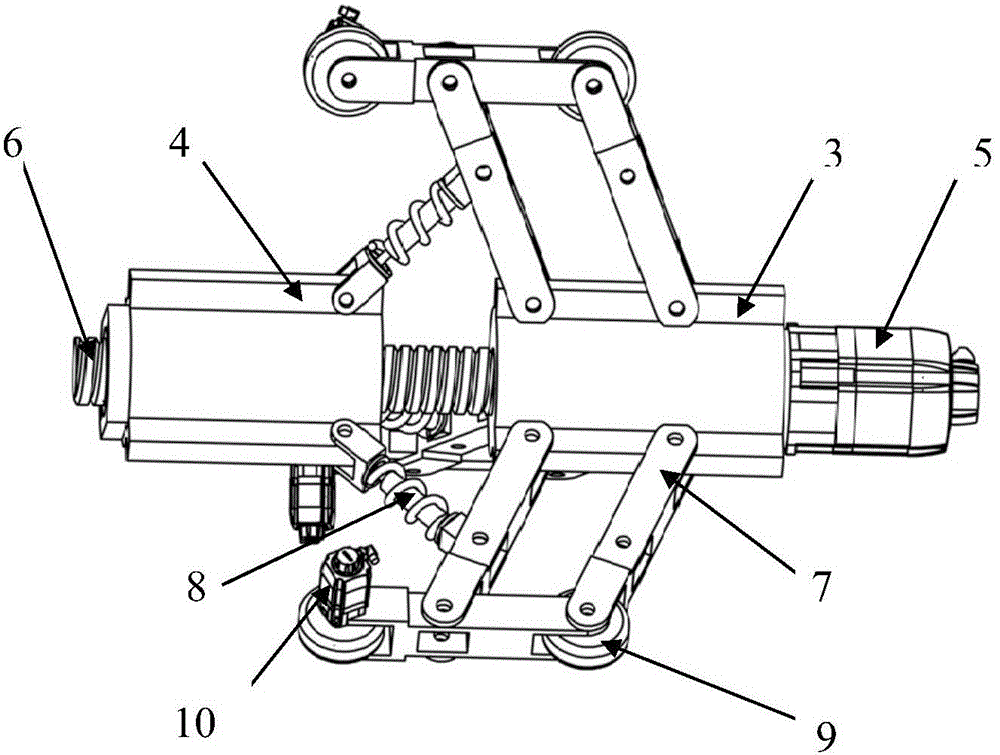

[0015] see Figure 1~Figure 2 , a pipeline threading robot, comprising a main body 1 and three feet 2 connected thereto with the same structure, the three feet are located in the circumferential direction of the main body cross-section, and any two of them form an angle of 120° with each other. The main body 1 is composed of a fixed block 3, a sliding block 4, a driving device 5, a lead screw 6 and the like. The fixed block 3 is fixedly connected to one side of the optical axis of the leading screw 6, the sliding block 4 is fixedly connected to the threaded side of the leading screw 6, and the driving device 5 is installed on one side of the fixed block 3 to drive the leading screw to rotate to realize the linear translation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com