Fully automatic multifunctional glass bottle cartoning machine

A multi-functional and fully automatic technology, applied in packaging, packaging bottles, transportation and packaging, etc., can solve the problems of glass bottles not being arranged in an orderly manner, manual finishing and sealing, and manual finishing, so as to achieve convenient pick and place, reduce the number of laborers, work reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

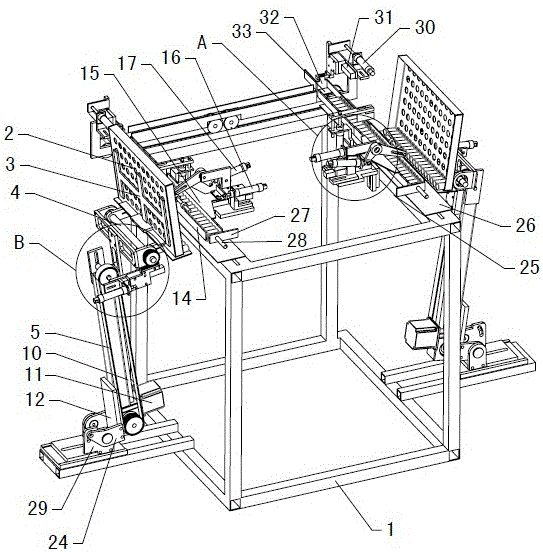

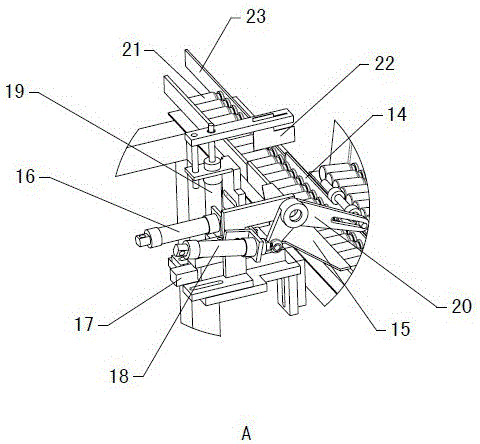

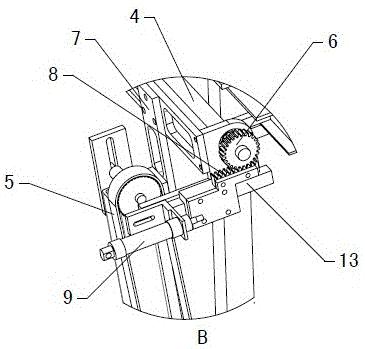

[0023] Figure 1~3 It is the best embodiment of this fully automatic multifunctional glass bottle cartoning machine, below in conjunction with the attached Figure 1~3 The present invention will be further described.

[0024] refer to figure 1 , the fully automatic multifunctional glass bottle cartoning machine comprises a frame 1, a base plate 26, a floating track plate 14, a bottle pushing plate 15 and a packing box 2, and the two sides of the frame 1 are symmetrically provided with a horizontal base plate 26, and on the base plate One side of 26 is provided with a packing box 2, and packing box 2 is vertically fixed on the packing box bracket 3, and the opening of packing box 2 faces the side that bottom plate 26 is arranged, and floating track plate 14 is vertical with pushing bottle into box plate 15. Set on the upper side of the bottom plate 26, the floating track plate 14 is located on the side close to the packing box 2, and the glass bottles 21 are sequentially tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com