Chemical-resistant functional cable for new energy electric vehicle charging system

A chemical-resistant, electric vehicle technology, applied in the direction of power cables including electric control, power cables including electrical communication lines, power cables, etc., can solve the problems of insulation and sheath aging, low cable service life, and cable sheath turtles. cracks and other problems, to achieve the effect of excellent electrical insulation performance, recycling cost, compression resistance, softness and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

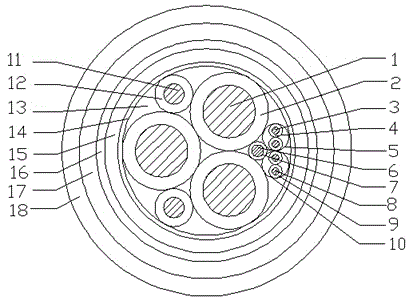

[0022] see figure 1 , an armored cable for a new energy electric vehicle conductive charging system, characterized in that the main structure includes 3 main power lines (1, 2), 2 auxiliary power lines (11, 12), and 1 pair of shielded charging communication lines (3, 4, 5), 1 pair of shielded charging connection confirmation wires (8, 9, 10) and 1 spare control signal wire (6, 7), outer filler (13) is provided in the twisted gap of the main structure, the main body The outside of the structure is sequentially wrapped with an outer cladding layer (14), an outer reinforced shielding layer (15), an outer inner sheath (16), an outer metal layer (17) and an outer sheath (18); the metal layer ( 17) It is made of longitudinal welding of aluminum st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com