Shielding device for ore pulp outlet of mineral separation system

A technology of shielding device and ore pulp, which is applied in the direction of solid separation, can solve the problems of interrupting production continuity, large influence range, large loss, etc., and achieves the effect of convenient and fast on-off, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

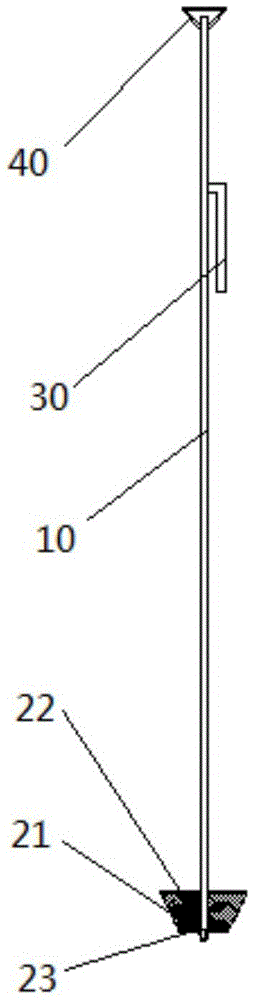

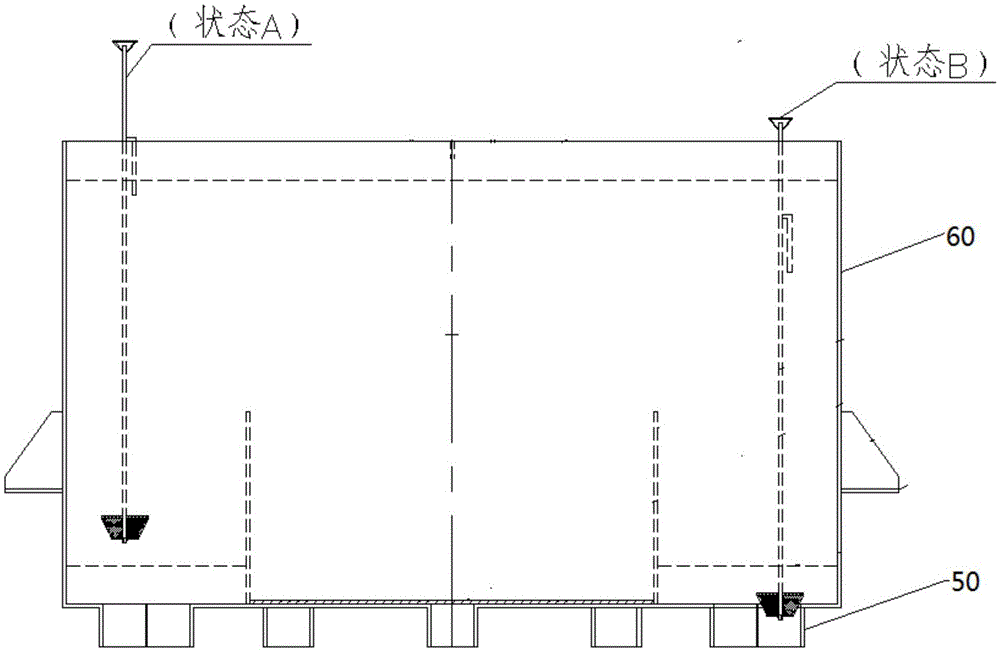

[0022] see figure 1 and 2 , The shielding device for the pulp outlet of the mineral processing system includes a joystick 10 with a large dead weight, and the joystick is a steel joystick.

[0023] The lower end of the joystick 10 is provided with a plugging piece for blocking the pulp outlet, and the plugging piece includes a conical rubber plug 21 with a large upper part and a smaller lower part. The conical rubber plug is clamped by upper and lower gaskets (22, 23). Gaskets (22, 23) are steel gaskets. Joystick runs through upper gasket 22, rubber plug 21, lower gasket 23, and the end of lower gasket 23 is tightened by a pair of locknuts (not marked in the figure), keeps certain pretightening force, prevents from coming off. A 10x10mm ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com