Aluminum rod pulling-out device used for aluminum rod roll

A pull-out device, aluminum rod technology, applied in the direction of wire drawing dies, etc., can solve the problems of reducing the work intensity of production staff, destroying the bonding state of aluminum rods, etc., and achieve the effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

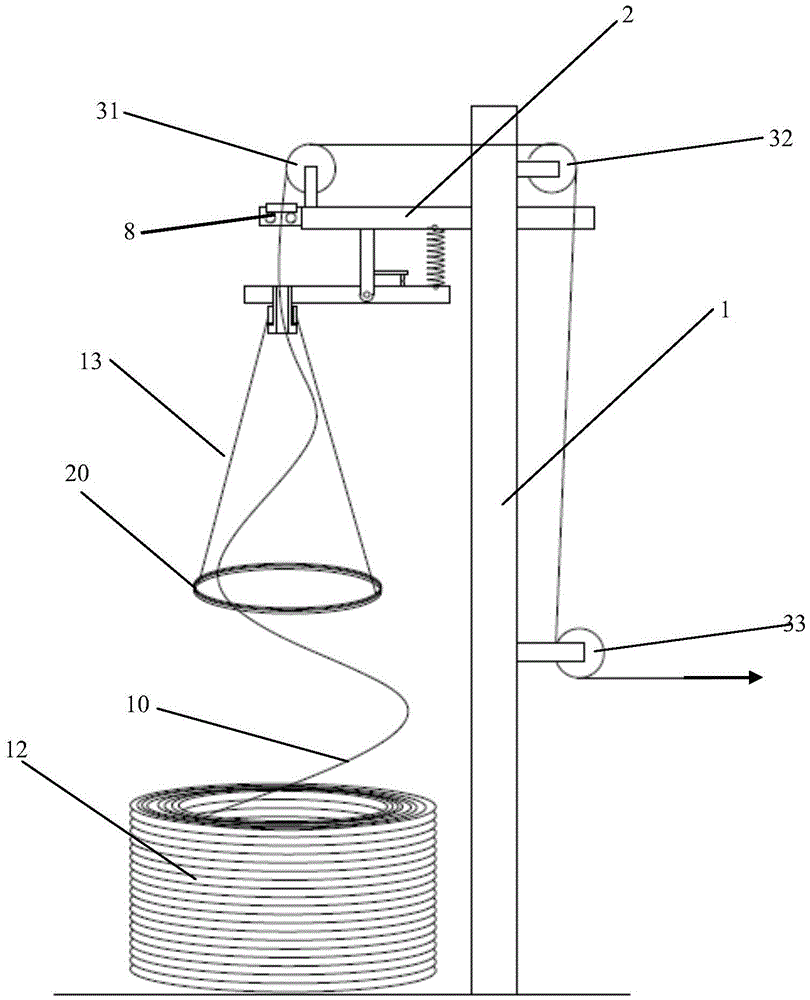

[0028] Embodiment 1: An aluminum rod pulling device for aluminum rod coils, including a column 1, a cross bar 2 and at least three guide wheel assemblies 3, the rear end of the cross bar 2 is fixed on the upper part of the column 1, the The first and second guide wheel assemblies 31 and 32 of the three guide wheel assemblies 3 are installed on both ends of the crossbar 2 respectively, and the third guide wheel assembly 33 of the three guide wheel assemblies 3 is installed in the middle of the column 1;

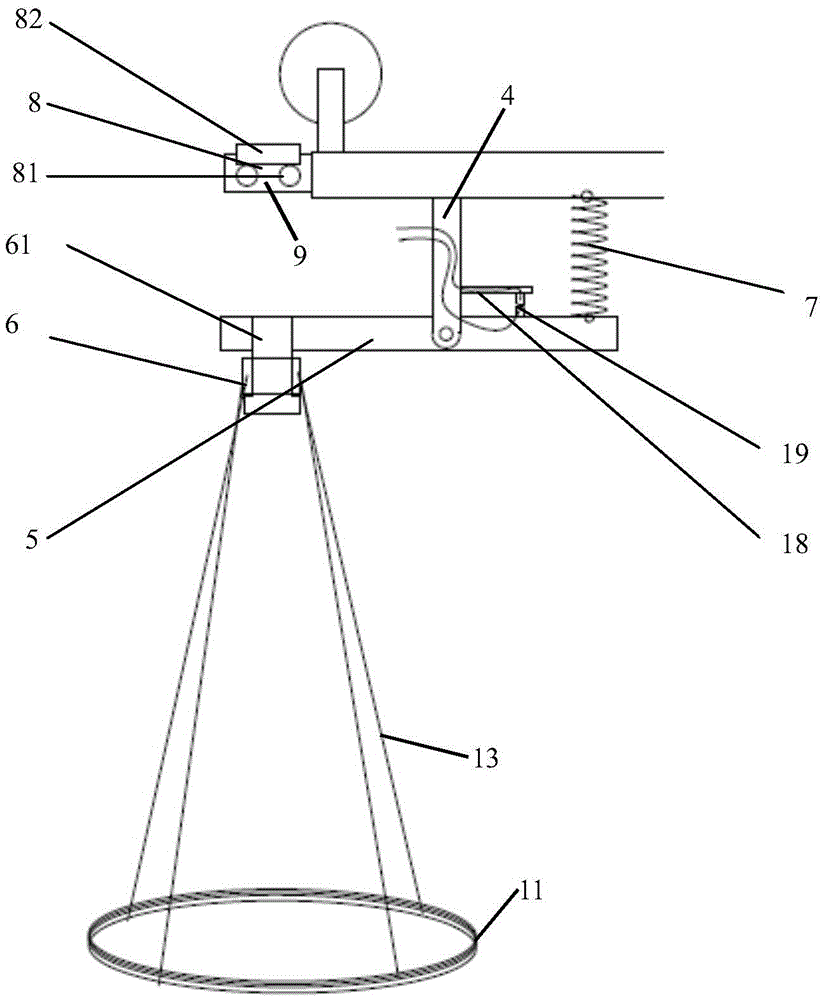

[0029] The crossbar 2 is fixed with a hanger 4 located below it, and the middle part of a plate body 5 is movably installed on the lower end of the crossbar 2, and the end of the plate body 5 away from the column 1 is equipped with a half mold 6. A spring 7 is arranged between the end of the plate body 5 close to the column 1 and the cross bar 2, a control switch for controlling the working state of the wire drawing machine is installed on the plate body, a detection contact is...

Embodiment 2

[0046] Embodiment 2: An aluminum rod pulling device for aluminum rod coils, including a column 1, a cross bar 2 and at least three guide wheel assemblies 3, the rear end of the cross bar 2 is fixed on the upper part of the column 1, the The first and second guide wheel assemblies 31 and 32 of the three guide wheel assemblies 3 are installed on both ends of the crossbar 2 respectively, and the third guide wheel assembly 33 of the three guide wheel assemblies 3 is installed in the middle of the column 1;

[0047] The crossbar 2 is fixed with a hanger 4 located below it, and the middle part of a plate body 5 is movably installed on the lower end of the crossbar 2, and the end of the plate body 5 away from the column 1 is equipped with a half mold 6. A spring 7 is arranged between the end of the plate body 5 close to the column 1 and the cross bar 2, a control switch 18 for controlling the working state of the wire drawing machine is installed on the plate body 5, and a detection c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com