Laser welding head adjusting device for T-shaped joint wire filling laser welding

A technology of laser welding head and adjusting device, which is applied to laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inconvenient adjustment of laser welding focus position and wire feeding position, and achieve the effect of effective laser incidence angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

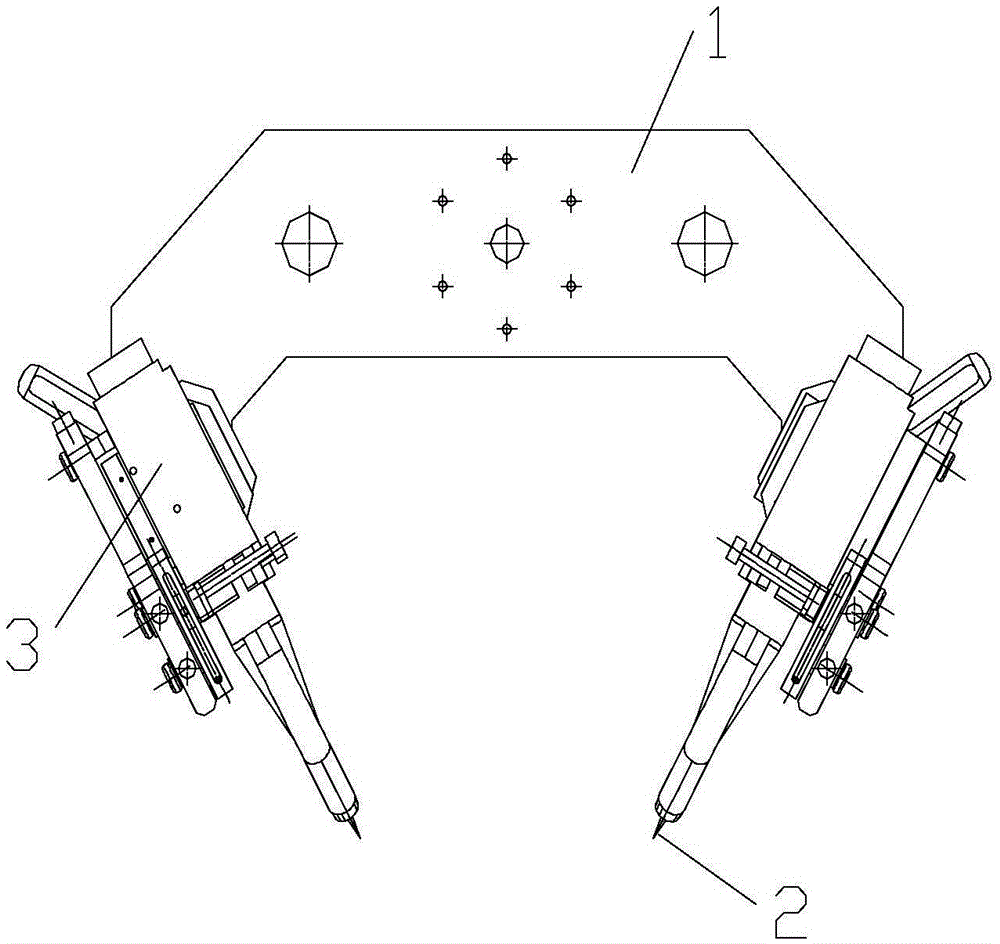

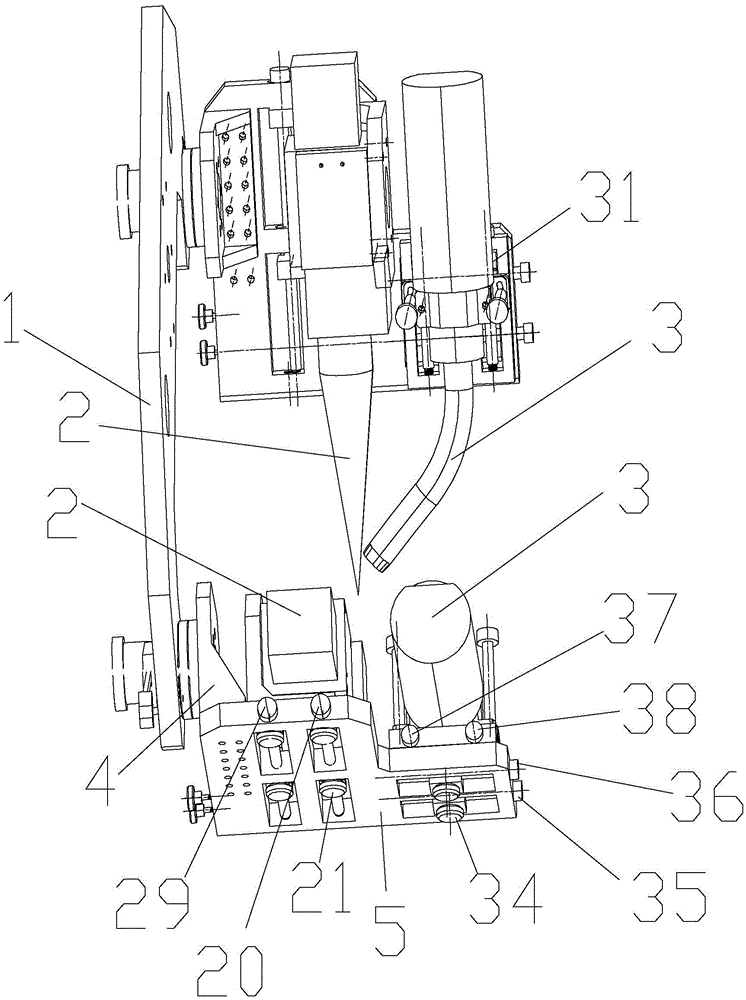

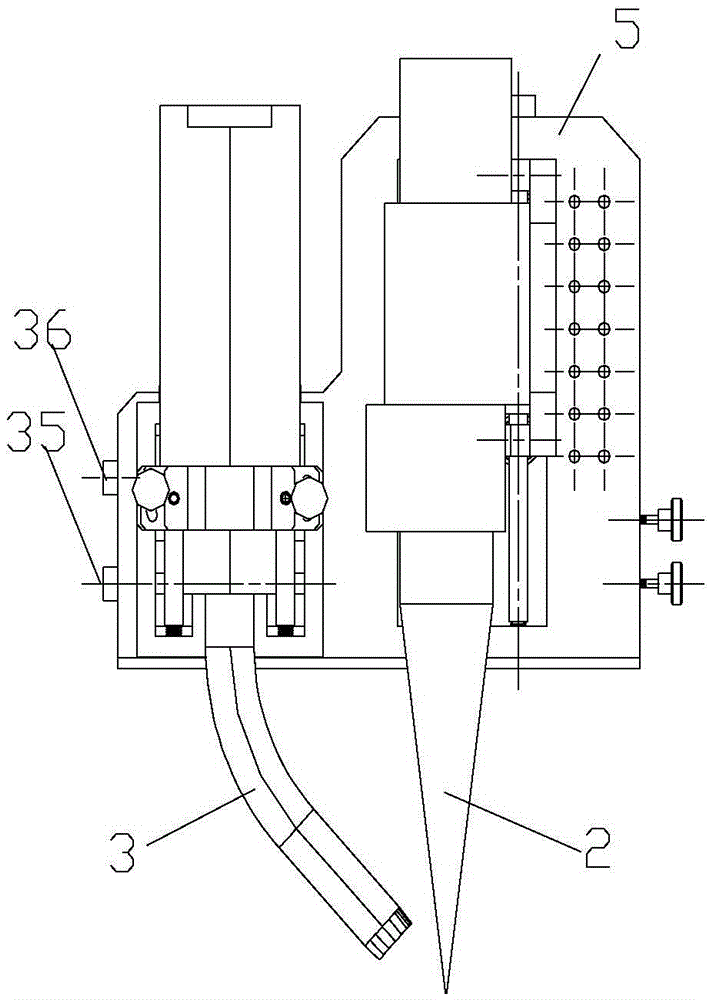

[0046] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the laser welding head adjustment device for T-joint laser wire filler welding according to the embodiment of the present invention includes:

[0047] The connection plate 1 of the T-joint;

[0048] The mounting bracket 5 is hinged on the connecting plate 1, for example, hinged on the connecting plate 1 through the adapter plate 4;

[0049] The laser welding head 2 is installed on the mounting bracket 5;

[0050] Wire feed head 3; installed on the mounting bracket 5;

[0051] The laser welding head slide bar mechanism is connected between the laser welding head 2 and the mounting bracket 5, or in other words, the laser welding head 2 is slidably arranged on the mounting bracket 5;

[0052] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com