Fertilizing and seeding device for precision seeder

A sowing device and seeder technology, which is applied to the parts of the planter, sowing, application, etc., can solve problems such as equipment damage, ditch opener or back soil pressure wheel vibration, and impact on seeding accuracy, so as to facilitate installation and avoid severe vibration , to ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

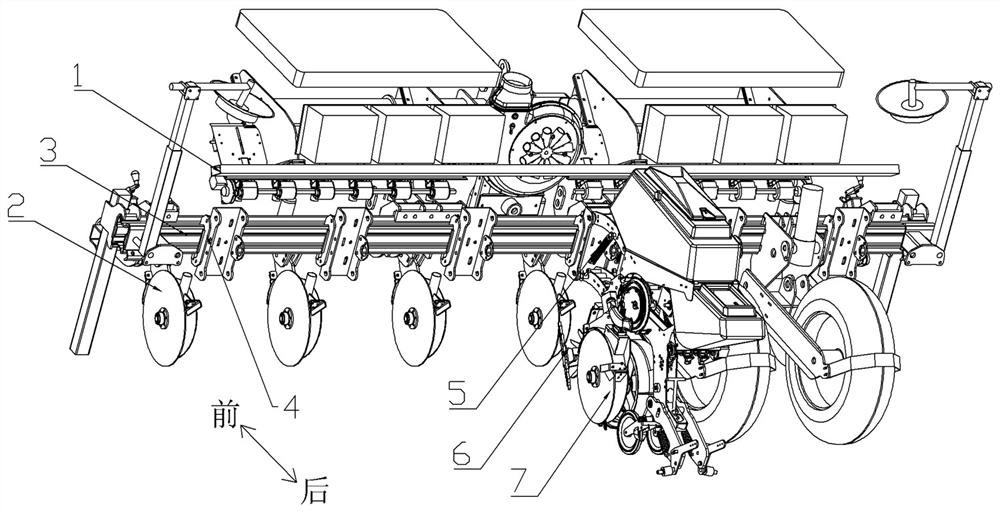

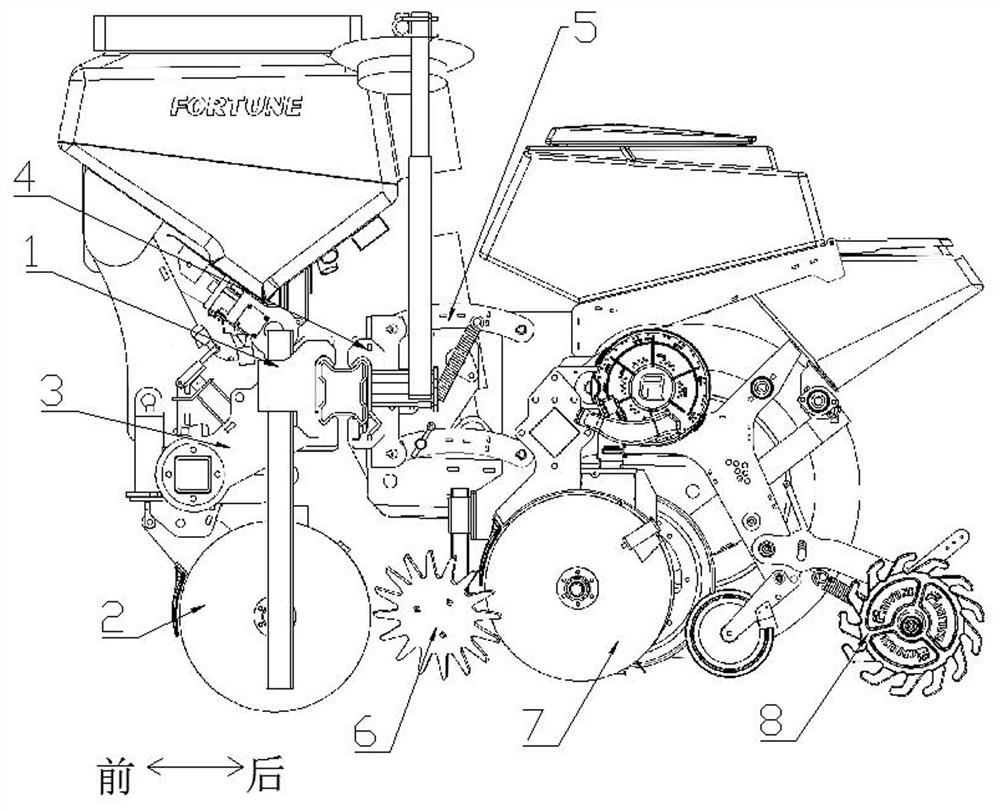

[0082] Embodiment A kind of fertilization and seeding device for precision seeder

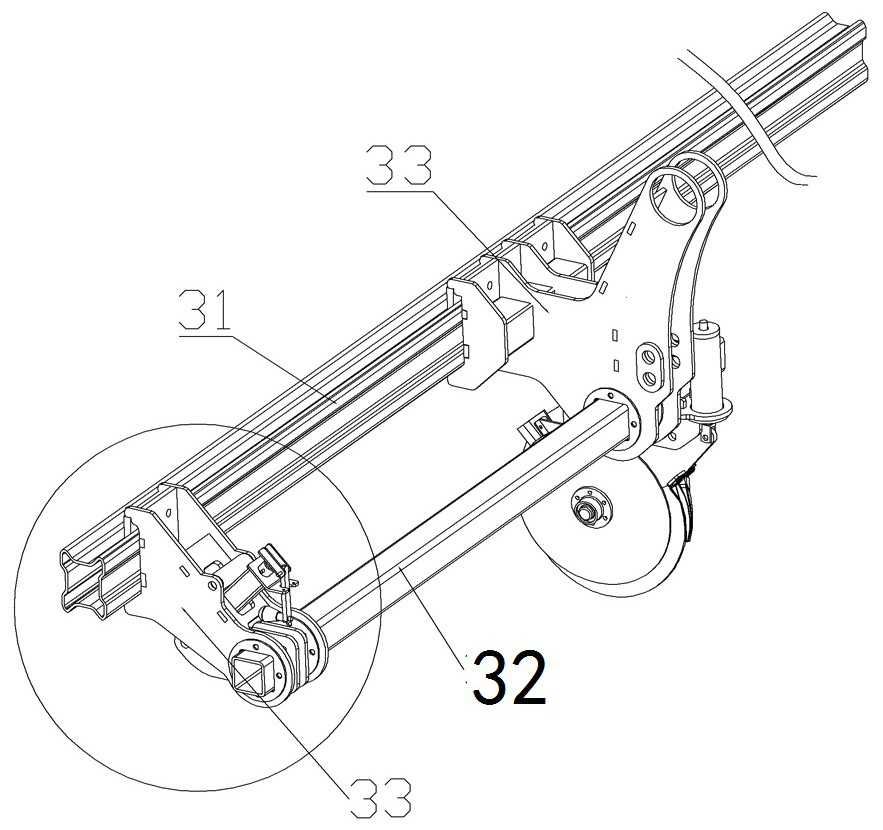

[0083] During sowing work, fertilization is carried out in the fertilization ditch by the fertilization mechanism 2 earlier, then the sowing back soil mechanism opens the sowing ditch at the side of the fertilization ditch, then sows in the sowing ditch, applies mouth fertilizer, returns soil to suppress. Therefore, if Figure 1 to Figure 2 Shown, the present embodiment comprises fertilizing mechanism 2, suspension connecting mechanism and sowing soil returning mechanism from front to back by the direction of travel. Wherein, each group of sowing and returning soil mechanism includes hook plate 4, parallel connecting rod 5, mowing wheel 6, sowing assembly 7 and soil returning suppression assembly arranged in sequence from front to back, and sowing assembly 7 includes ditch opener 71, seed row Device 73, seed introduction pipe 72, depth-limiting wheel 74 and mouth fertilizer assembly. Returnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com