Ventilation cover plate assembly for vehicle

A technology for ventilation cover and assembly, which is applied to the superstructure sub-assembly, vehicle components, upper structure and other directions, can solve the problems of increased maintenance cost, damage to the installation structure of the ventilation cover, waste of man-hours, etc., to improve assembly quality and Appearance quality, the effect of avoiding assembly clearance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

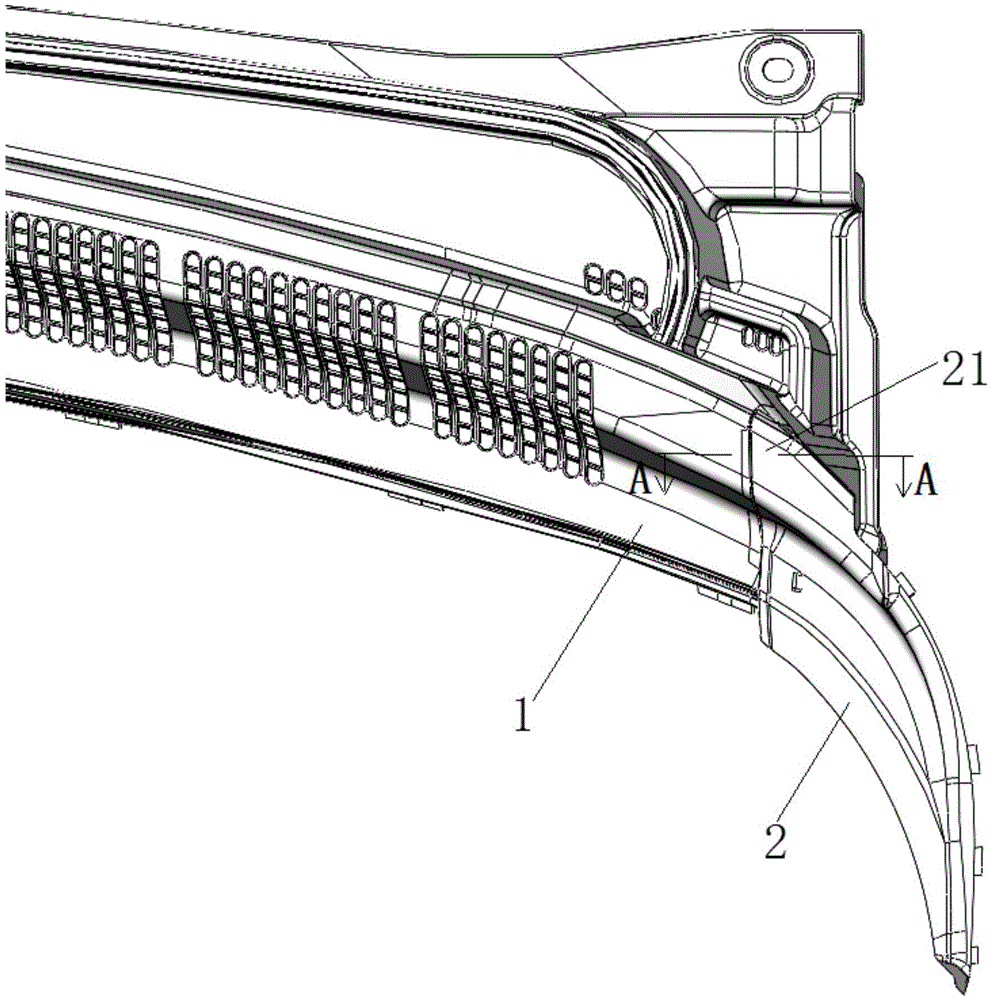

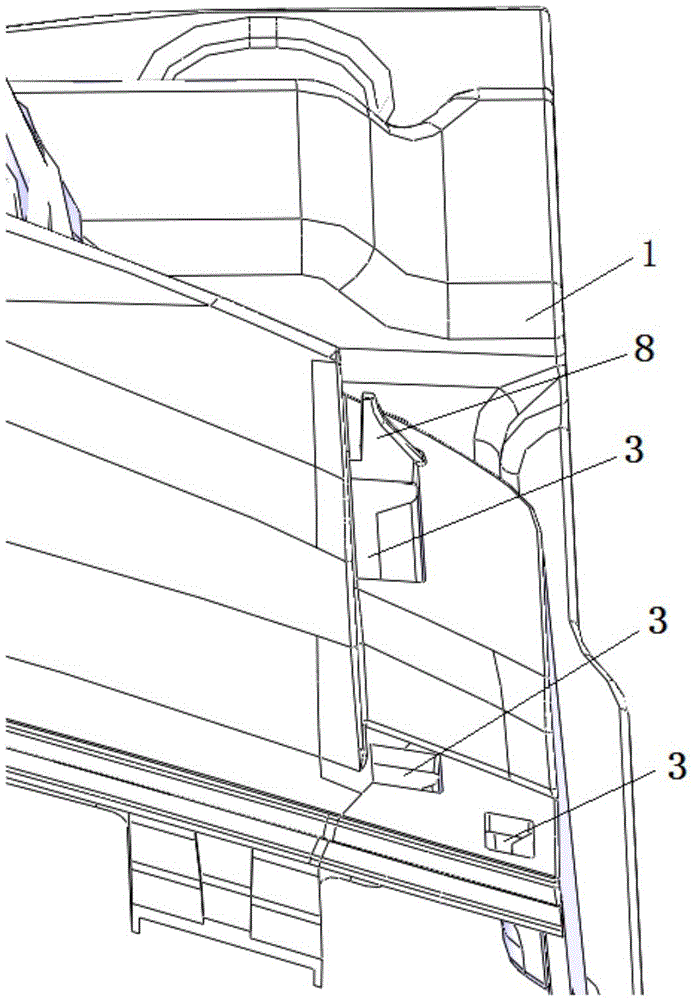

[0020] Such as Figures 1 to 7 , is an automobile ventilation panel assembly, comprising a ventilation panel body 1 and end caps 2 connected to both sides of the ventilation panel body 1, the ventilation panel body 1 and the end covers 2 are clamped and connected, and the ventilation The two sides of the cover body 1 are symmetrically provided with a plurality of slots 3 , and the end cover 2 is correspondingly provided with a plurality of buckles 4 , and the buckles 4 are fitted into the slots 3 respectively.

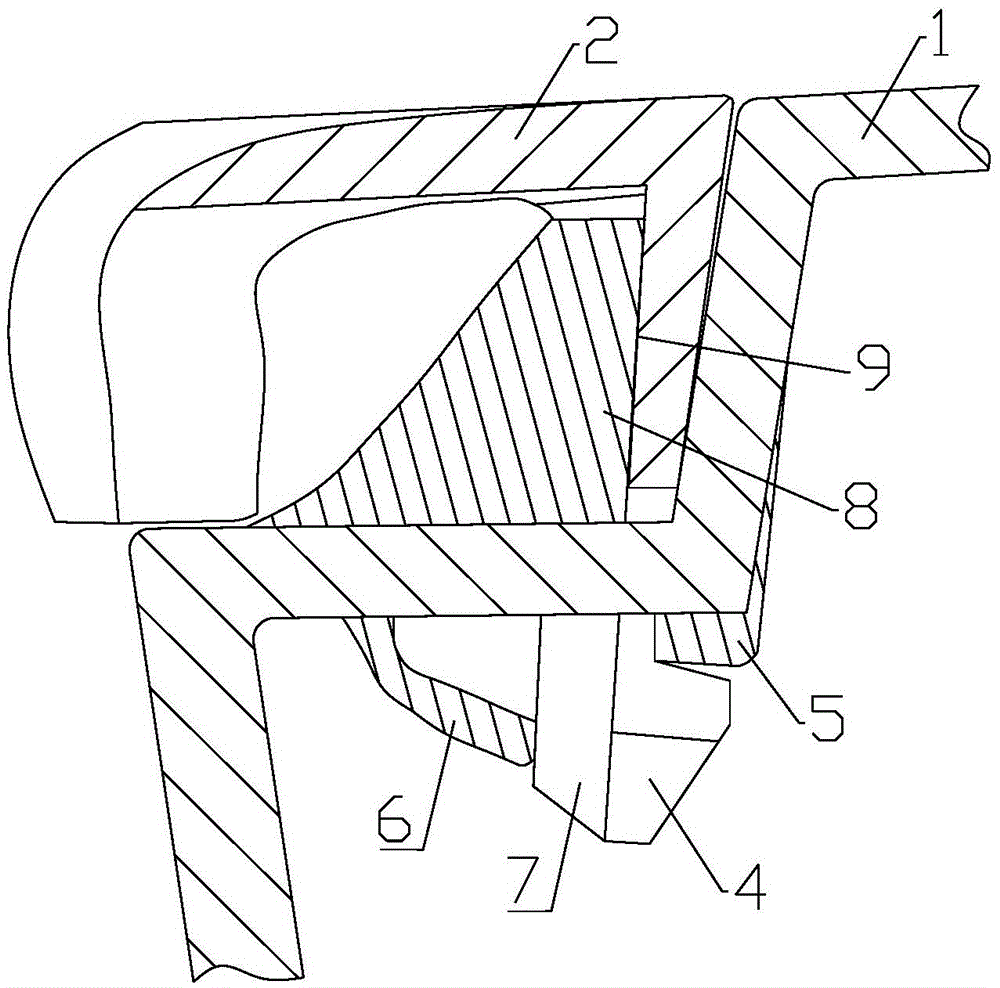

[0021] Specifically, such as Figure 5 As shown, a clamping plate 5 and a limiting plate 6 are arranged at the lower end of the clamping groove 3, the buckle 4 is clamped on the lower end surface of the clamping plate 5, and the limiting plate 6 is arranged obliquely relative to the direction of the clamping plate 5 for Fasten the clip 4 on the clip plate 5 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com