Inclined dumper door of freight carriage

A tilting, carriage technology, applied in the superstructure, vehicle parts, transportation and packaging of trucks, can solve the problems of labor-intensive, rollover, no self-unloading technology, etc., to improve safety and convenience sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

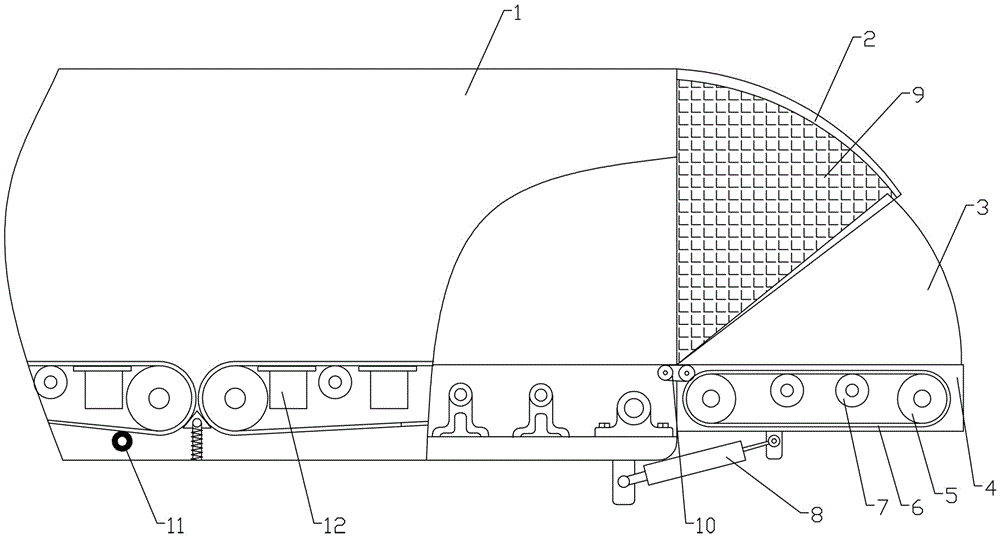

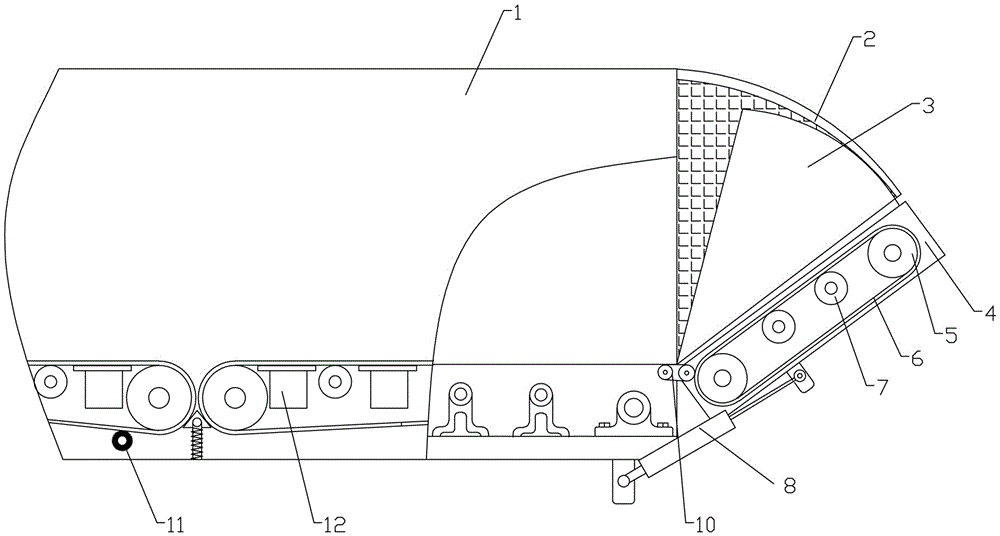

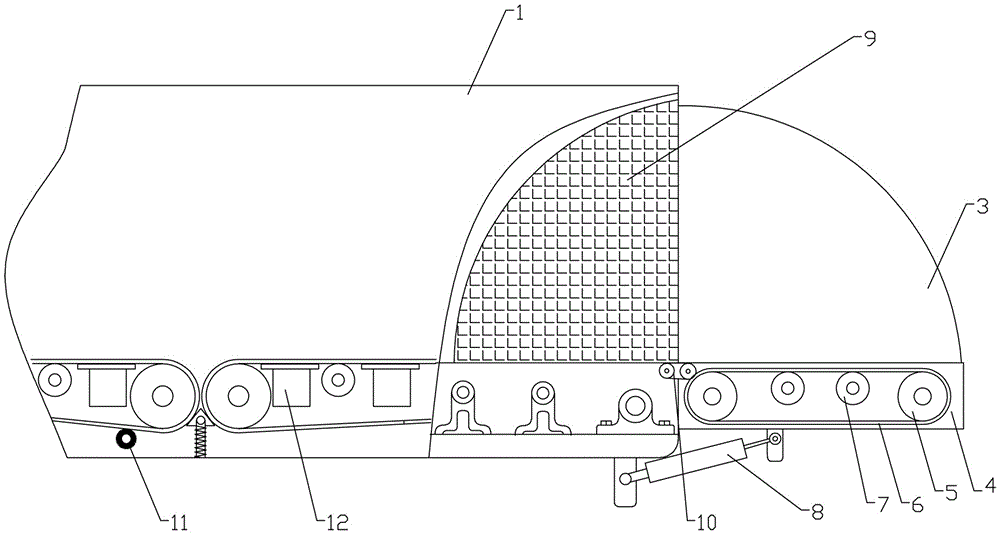

[0024] A protruding triangular side plate 2 is provided at the rear of the compartment 1, and the side plate 2 is provided with the above-mentioned protective plate inserting groove 9.

Embodiment 2

[0026] The inner side of the rear part of the compartment 1 is provided with the above-mentioned guard plate embedding groove 9 .

[0027] work process:

[0028] Start the telescopic rod, the guide rod of the telescopic rod shrinks, drives the bottom beam to rotate around the hinge, and realizes that the curved guard plate falls from the embedded part along with one end of the conveying bottom plate to the bottom of the box as a whole, and stops falling. At the same time, the conveyor belt starts to start unloading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com