A current receiver lifting shoe mechanism

A current collector and lifting shoe technology, which is applied in the field of rail transit, can solve the problems of potential safety hazards, inability to use under the train, long length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

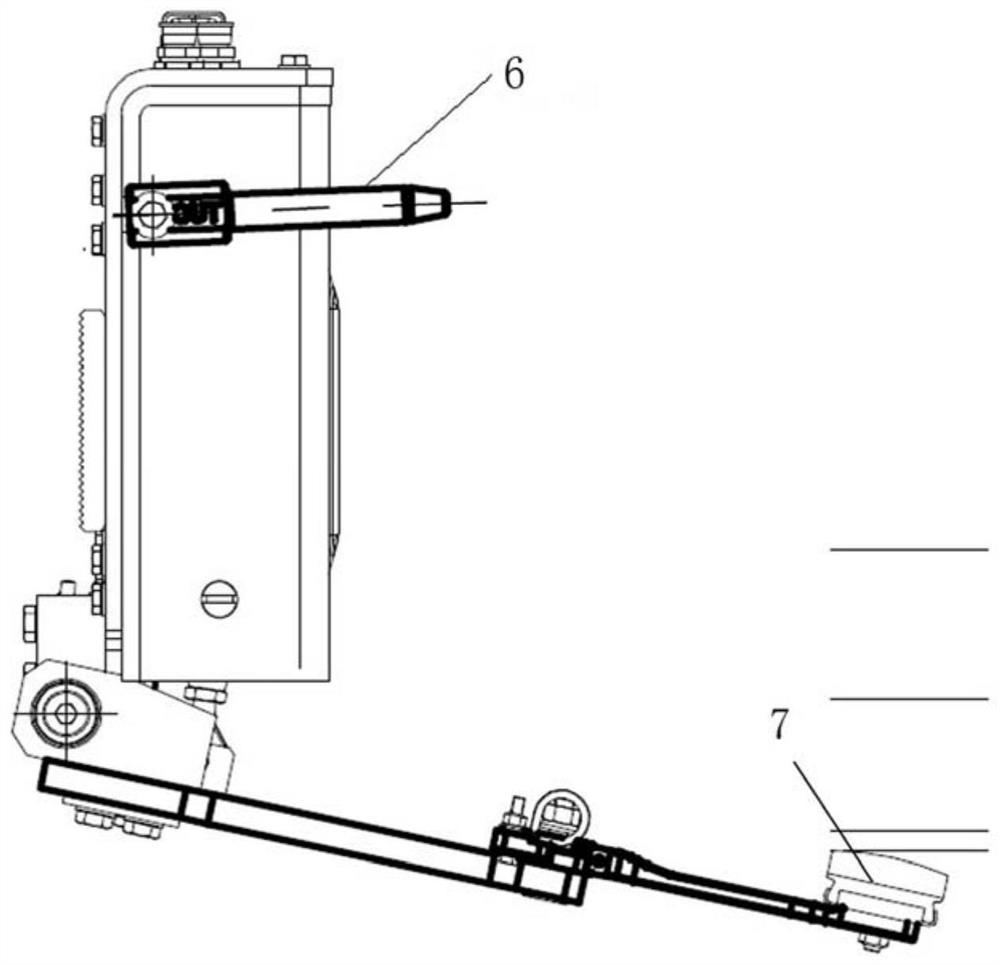

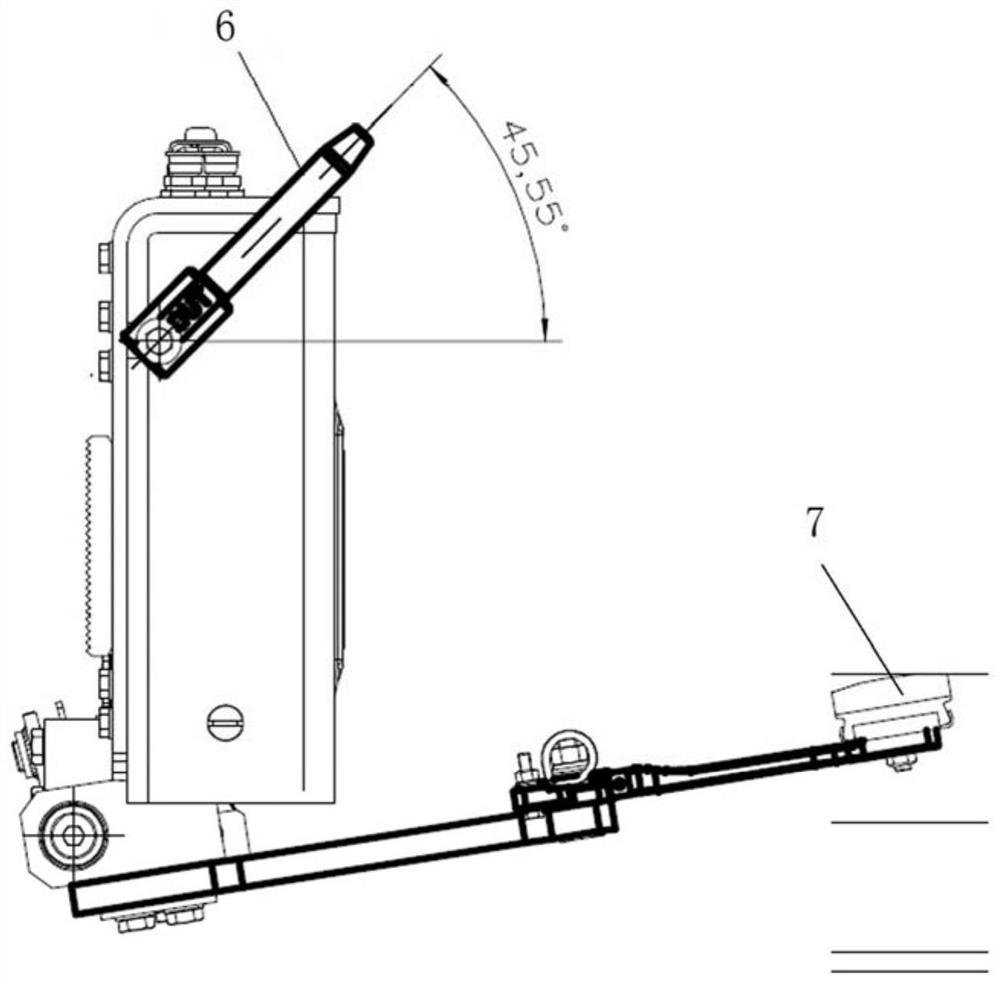

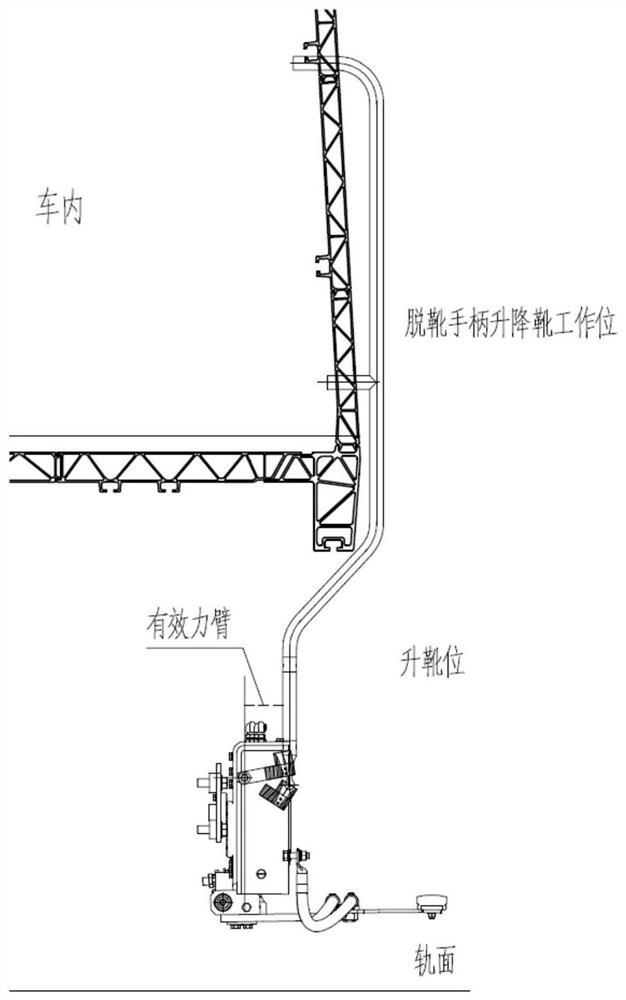

[0038] Such as Figure 4 and Figure 5 As shown, the current collector lifting shoe mechanism in this embodiment includes a long boot handle 1 and a short boot handle 2 hinged to the long boot handle 1, and the hinged end of the long boot handle 1 is fixed through the shaft hole interference fit. There is a limiter 3, and the hinged end of the short boot handle 2 is fitted with a hinge 4 through the threaded shaft hole. The limiter 3 is provided with a hinge groove 31 on the side facing the hinge 4, and the end of the hinge 4 extends into the In the hinged groove 31 and hinged with the stopper 3, the hinged groove 31 is provided with an avoidance space for the hinged part 4 to swing around the hinge point; thus making the long boots-off handle 1 and the short boots-off handle 2 both in the long boots-off handle Rotate around the hinge point in the plane formed by the centerline of 1 and the centerline of short boot handle 2.

[0039] Such as Figure 6 As shown, the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com