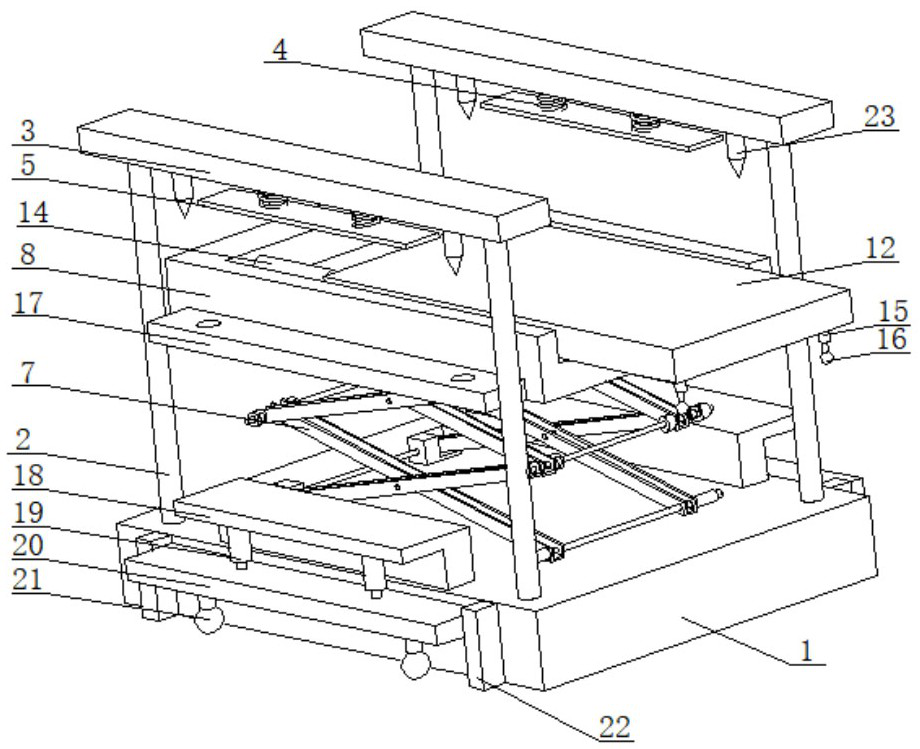

Vertical lifting device in construction

A vertical lifting and construction technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of increasing the physical labor of construction personnel, causing danger to construction personnel, and failing to achieve lifting accuracy, so as to facilitate material handling, improve safety, Reduce the effect of physical labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

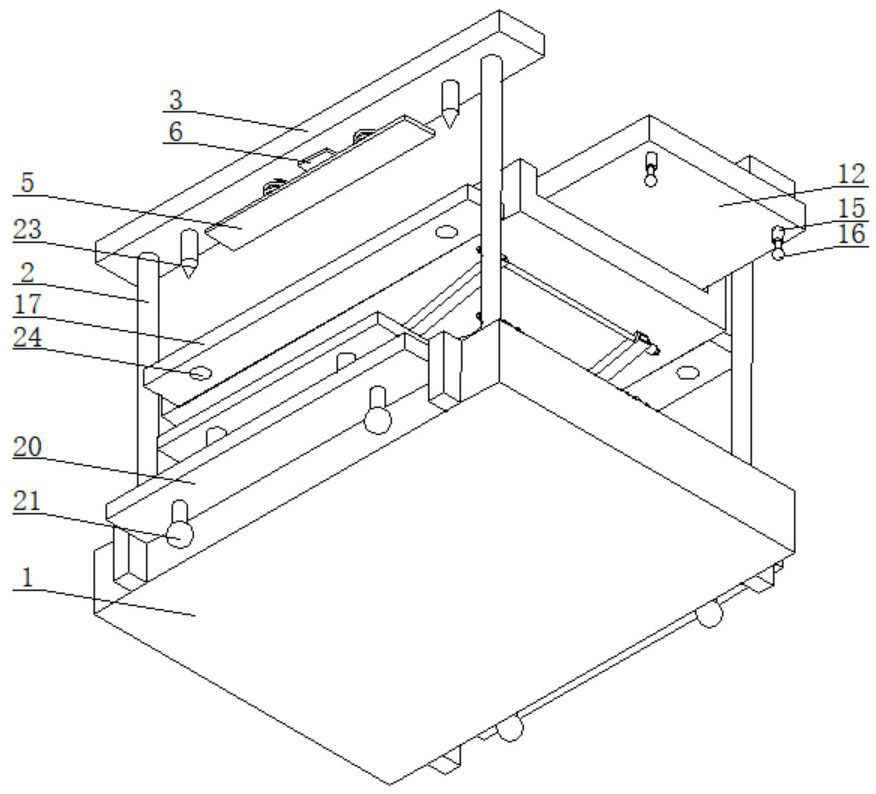

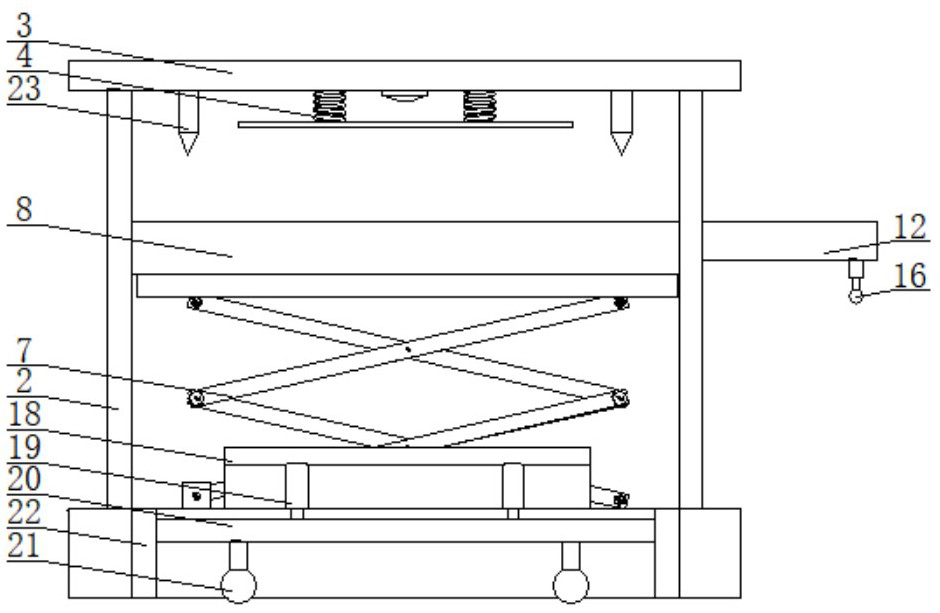

[0030] When using the device, first move the device to the use position, then place the material on the sliding plate 12, then the scissor lift mechanism 7 works, the scissor lift mechanism 7 drives the placing plate 8 to move upward, and the placing plate 8 moves to drive the connection The plate 17 moves upward with the material, the connecting plate 17 moves upward and contacts the pressure plate 5, the connecting plate 17 contacts the pressure plate 5 and drives the pressure plate 5 to move upward, the spring 4 is compressed, and the pressure plate 5 drives the elastic contact piece to contact the travel switch 6, and the shear The fork lift mechanism 7 stops working, then the first telescopic rod 14 works, the first telescopic rod 14 stretches and drives the connecting block 13 to move toward the direction of the construction worker, the connecting block 13 moves to drive the sliding plate 12 to move, and the sliding plate 12 moves to drive the roller 16 When moving, the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com