Hydraulic ejection system for unmanned aerial vehicle

An unmanned aerial vehicle, hydraulic technology, applied in the direction of launch / tow transmission device, can solve the problems of poor maneuverability, harsh environmental requirements, low initial investment, etc., to achieve rapid buffer braking, compact pipeline layout, and stable overall performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention. Apparently, the described embodiments are only illustrative partial implementations of the present invention, and are not intended to limit the scope of the present invention. , any equivalent changes and modifications made by those skilled in the art without departing from the concepts and principles of the present invention shall fall within the protection scope of the present invention.

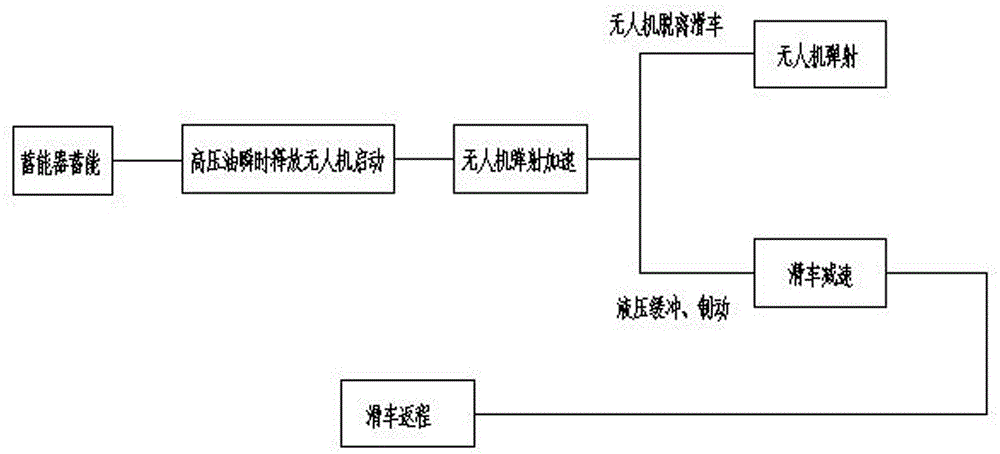

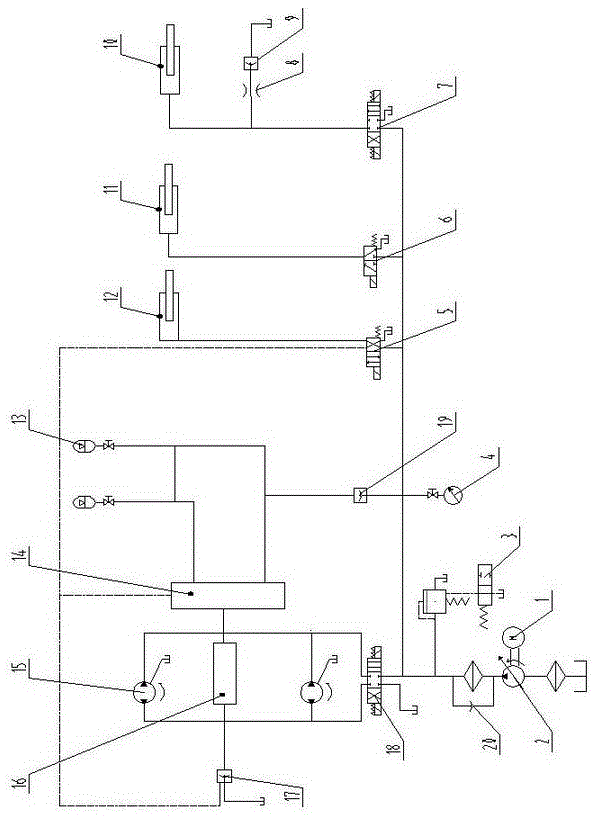

[0034] see figure 1 , in the figure, the UAV hydraulic ejection system of the present invention includes a hydraulic drive part, a hydraulic energy storage part, a hydraulic start part, a hydraulic buffer part, a hydraulic brake part, a hydraulic oil tank, and a hydraulic pipeline for connection between each part Wherein, the hydraulic drive part includes a motor 1, a variable pump 2 and a hydraulic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com