Power source switching mechanism

A power source switching and power technology, applied in the field of packaging equipment parts, can solve problems such as double-layer boxing, and achieve the effect of promoting mass production, saving equipment and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

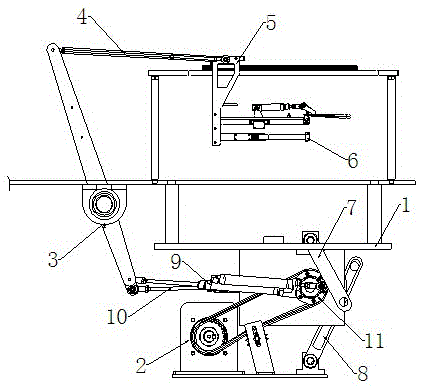

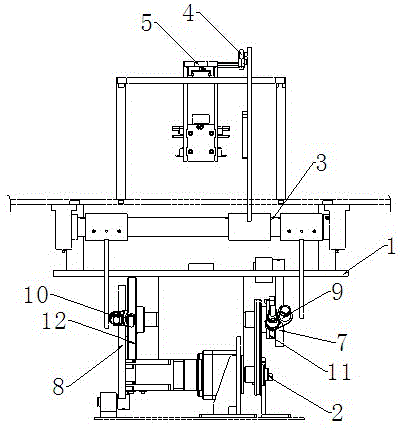

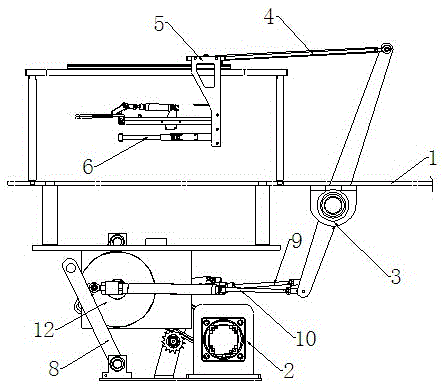

[0011] Depend on figure 1 It is known that a power source switching mechanism consists of a frame 1, a power assembly 2, a push handle swing rod 3, a connecting rod 4, a slider 5, an executive push handle 6, a power swing rod I7, a power swing rod II8, and a combined cylinder connecting rod I9 Composed of combined cylinder connecting rod II 10, the bottom of the frame 1 is equipped with a power assembly 2, which is connected to the driven mechanism on the frame 1, with a small wheel 11 at one end of the driven mechanism and a large wheel 12 at the other end; The upper end of the power swing rod I7 is flexibly connected to the frame 1, the lower end of the power swing rod I7 is flexibly connected to the combined cylinder connecting rod I9, and a chute is provided in the power swing rod I7 to be flexibly connected to the small wheel 11; the power swing rod II8 The lower end is movably connected to the bottom of the frame 1, the upper end of the power swing rod Ⅱ8 is movably conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com