Flat ground bin packing mechanism of bulk cargo container

A technology for bulk materials and containers, applied in conveyors, conveyor objects, loading/unloading, etc., which can solve problems such as troublesome packing, inability to fill space, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

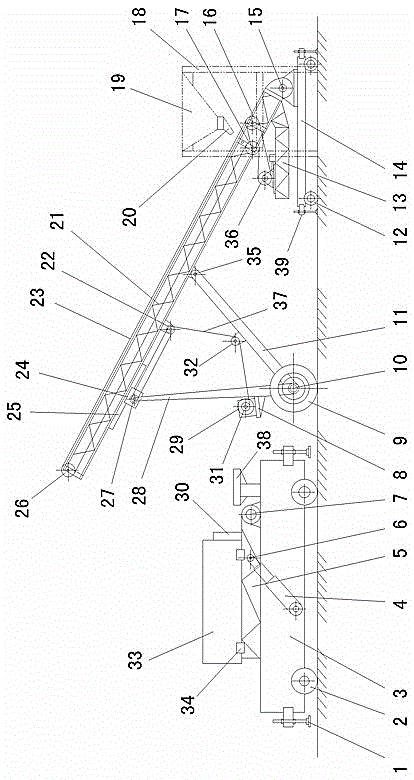

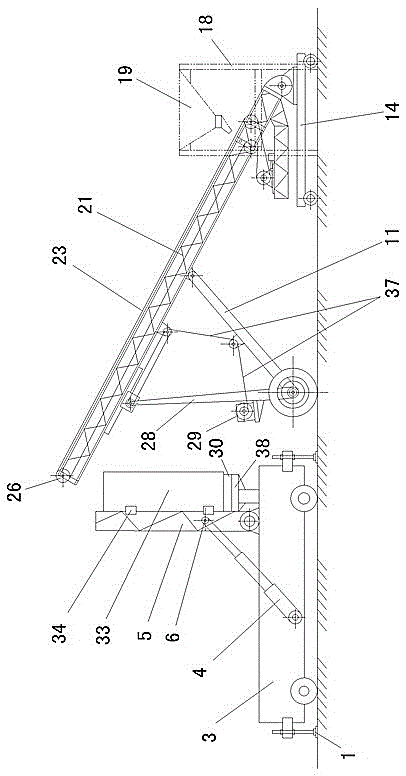

[0010] Such as figure 1 Shown: 21 is the conveying frame that is arranged obliquely, and the lower end of conveying frame 21 is connected with platform 14 through rotating shaft 15 of conveying frame. The transport frame 21 can be rotated relative to the platform 14 . Platform road wheels 12 are installed below the platform 14, so that the position can be changed by dragging. The side of platform 14 is equipped with adjustable support member 39, and adjustable support member 39 is identical with the support of existing hoisting crane, promptly can be hydraulic telescopic type or spiral telescopic type, to be conveniently and stably supported on the ground.

[0011] Below described delivery frame 21, be provided with inclined supporting device, inclined supporting device comprises supporting wheel 9, is connected with back supporting frame 11 and front supporting frame 28 by bearing rotation on the axle 10 of supporting wheel 9, and rear supporting frame 11 and front Both the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com