A hydraulic blasting demolition device and its demolition method

A technology of hydraulic blasting and detonating tube, which is applied in blasting, building maintenance, construction, etc., can solve the problems of high safety risk, heavy floor load, heavy drilling workload, etc., to facilitate installation and disassembly, reduce additional Good load and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

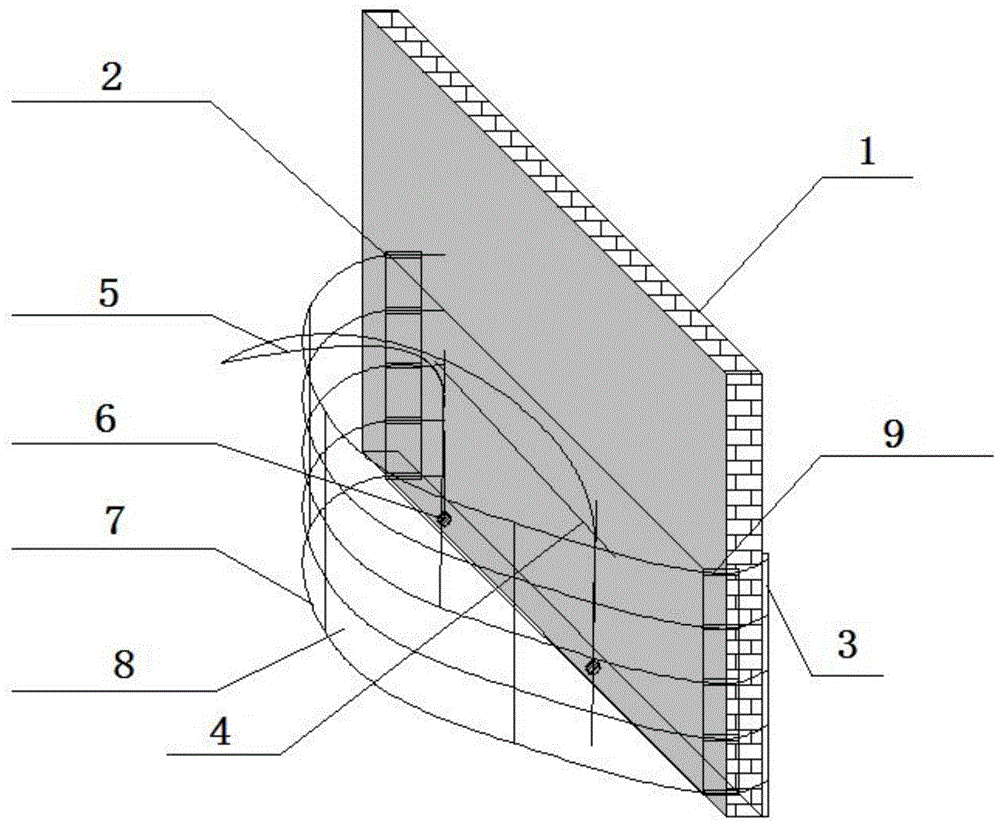

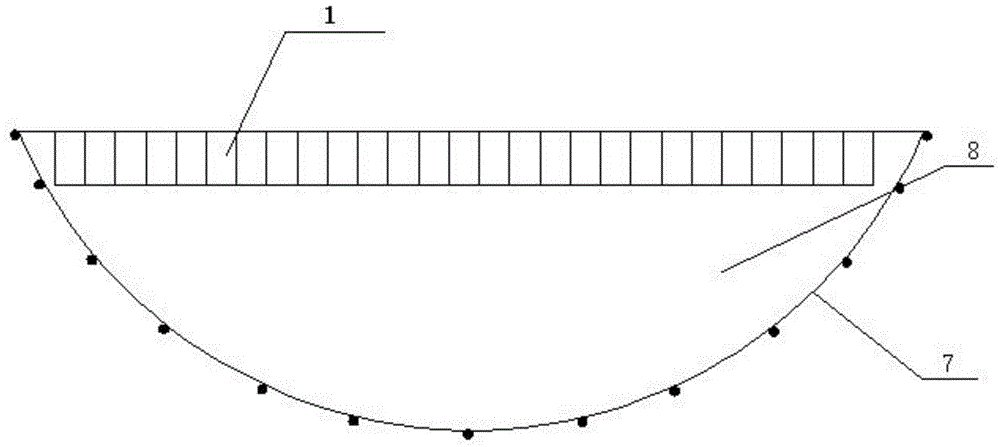

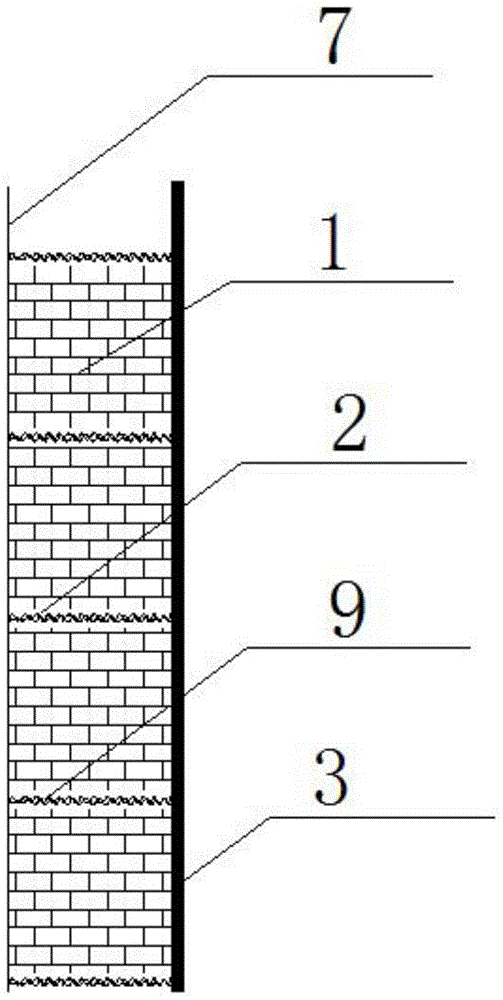

[0033] refer to Figure 1 to Figure 3 , a hydraulic blasting demolition device, comprising a wall body 1 to be demolished. A water storage container 8 and a water storage container skeleton 7 are also included. The water storage container 8 is fixed in the water storage container skeleton 7 , and the water storage container 8 is close to the water storage container skeleton 7 . The water storage container skeleton 7 is composed of longitudinal reinforcement and transverse reinforcement. In this embodiment, the number of transverse reinforcement bars is 5, and the number of longitudinal reinforcement bars is 10; the distance between the longitudinal reinforcement bars and the transverse reinforcement bars is 20cm; the diameter of the longitudinal reinforcement bars and the transverse reinforcement bars is 20mm. The water storage container skeleton 7 is arc-shaped, the chord length of the arc is 2m, and the distance from the midpoint of the chord to the top of the arc is 1.5m....

Embodiment 2

[0042] A hydraulic blasting demolition device includes a wall body 1 to be demolished. A water storage container 8 and a water storage container skeleton 7 are also included. The water storage container 8 is fixed in the water storage container skeleton 7 , and the water storage container 8 is close to the water storage container skeleton 7 . The water storage container skeleton 7 is composed of longitudinal reinforcement and transverse reinforcement. In this embodiment, the number of transverse reinforcement bars is 10, and the number of longitudinal reinforcement bars is 20; the distance between the longitudinal reinforcement bars and the transverse reinforcement bars is 30cm; the diameter of the longitudinal reinforcement bars and the transverse reinforcement bars is 25mm. The water storage container skeleton 7 is arc-shaped, the chord length of the arc is 3m, and the distance from the midpoint of the chord to the top of the arc is 1m. The material of water storage contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com