System plugging and draining structure for tunnel leakage treatment

A technology for drainage structures and tunnels, applied in drainage, tunnels, tunnel linings, etc., can solve problems such as failure to effectively cut off seepage channels, failure to effectively cut off groundwater, and unsatisfactory effects, and achieve good drainage effects and easy pipelines. Conservation, technical effect with remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now, in conjunction with the drawings, we will further explain how the present invention is implemented:

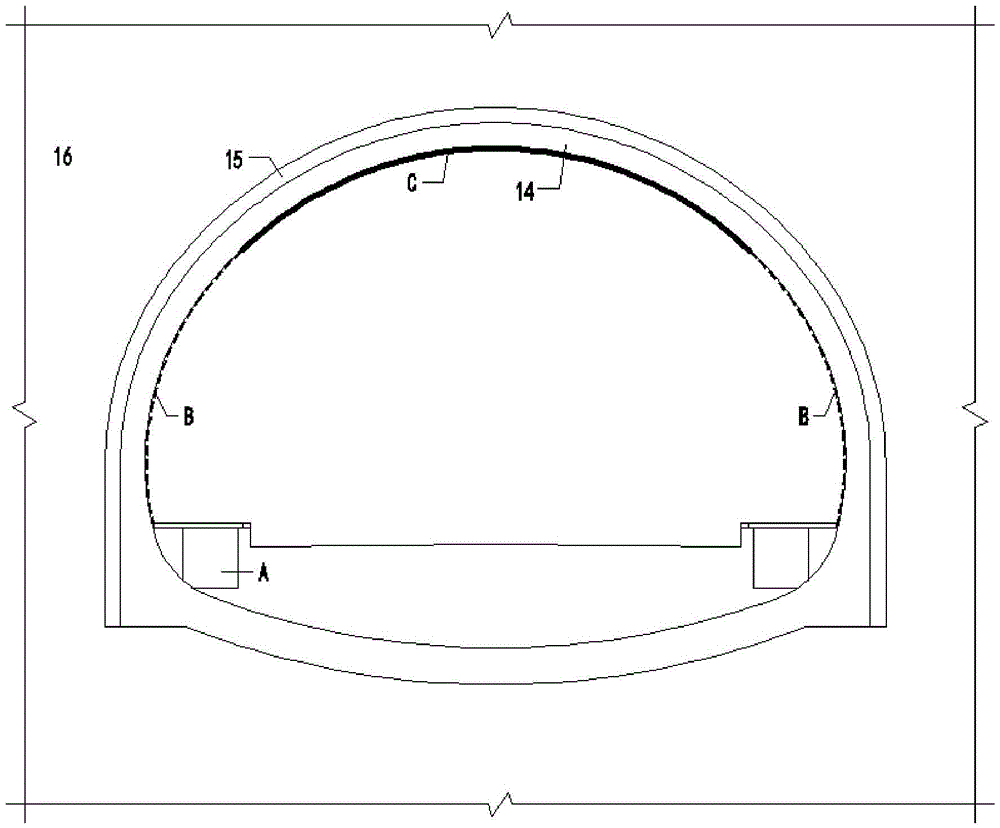

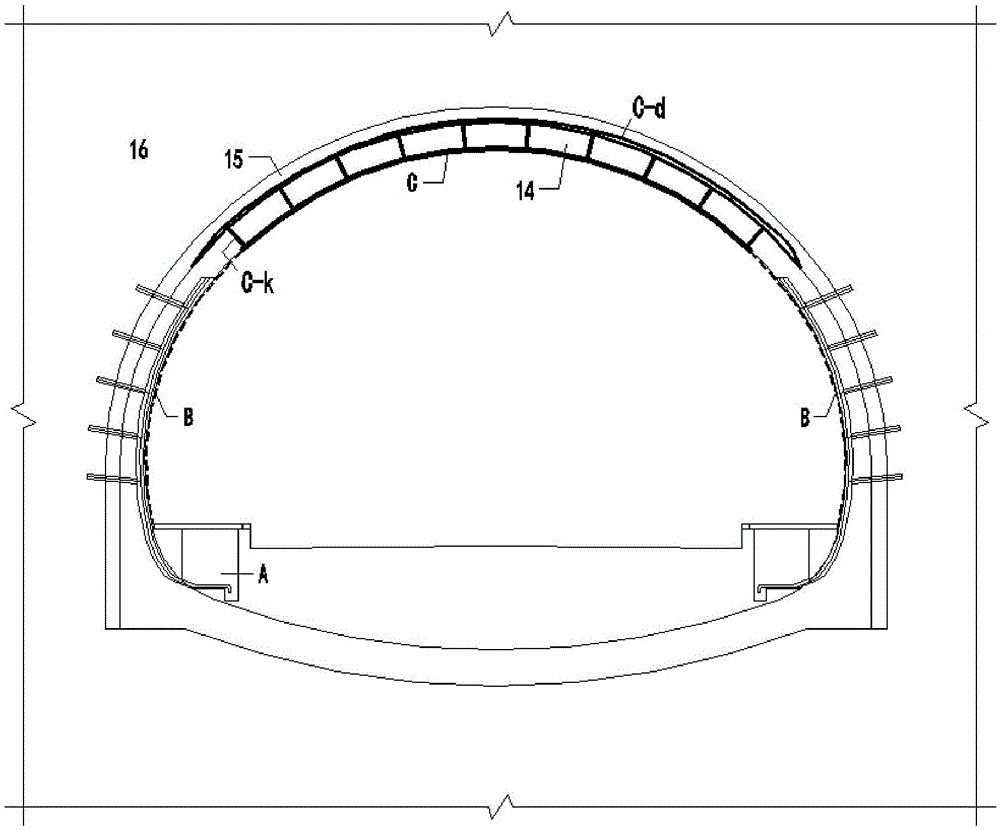

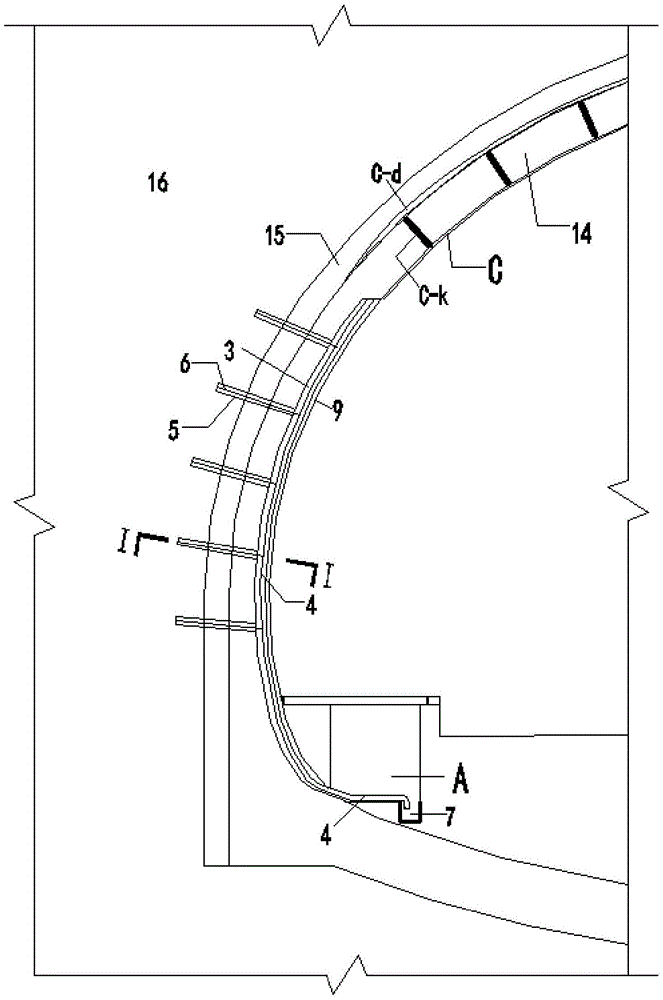

[0020] The existing tunnel structure can be summarized as follows: from bottom to top, there are pipe trench part A, circumferential side wall part B, and arch part C; from the inside to the outside, they are the secondary lining layer 14, the primary lining layer 15, and the surrounding Rock 16, such as figure 1 Shown.

[0021] The present invention is a system leakage stoppage and drainage structure for tunnel leakage treatment, which includes a leakage stoppage layer Cd at a tunnel arch part C and a built-in drainage pipeline Bp at a tunnel circumferential side wall part. The tunnel arch part C The plugging layer Cd is grouted inward through the grouting hole Ck opened in the arched part of the tunnel, and a stable grouting plugging layer is formed between the secondary lining layer 14 and the primary lining layer 15 of the arched part of the tunnel ,Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com