Double-parallel-PID-based control method of engine rotation speed management system and system

A technology of engine speed and control method, which is applied in the direction of engine control, machine/engine, electrical control, etc., can solve the problems that the engine speed cannot be unified and effectively managed, and achieve uniform and effective management of engine speed, simple operation, and avoid The effect of frequent switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

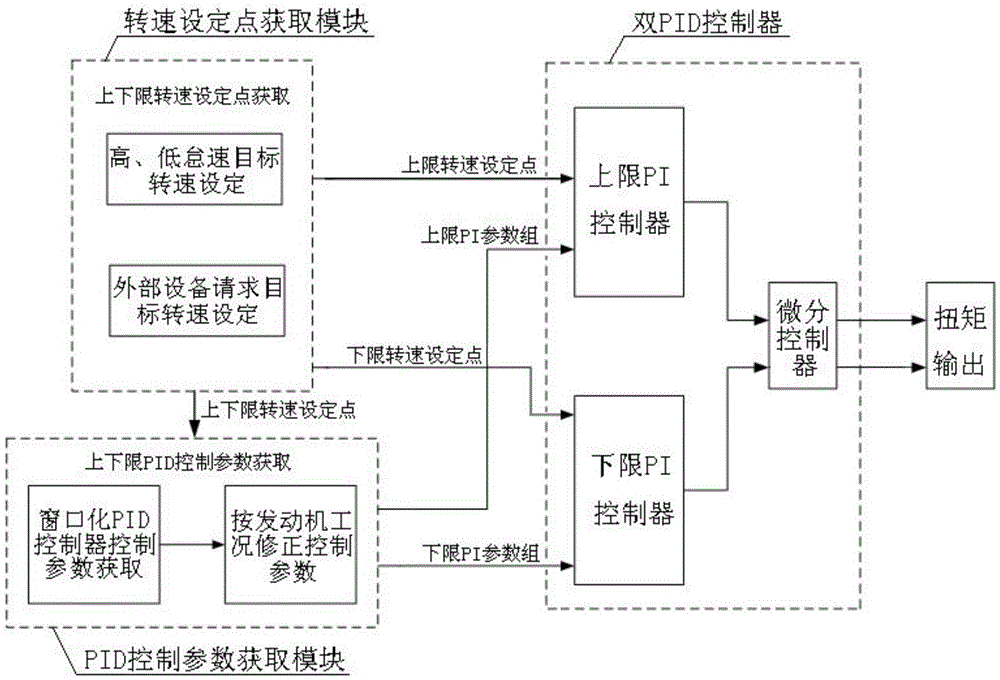

[0075] see Figure 1 to Figure 10 , a kind of control method of the engine management system based on parallel double PID, described control method comprises the following steps:

[0076] A. Acquisition of upper and lower limit speed set points:

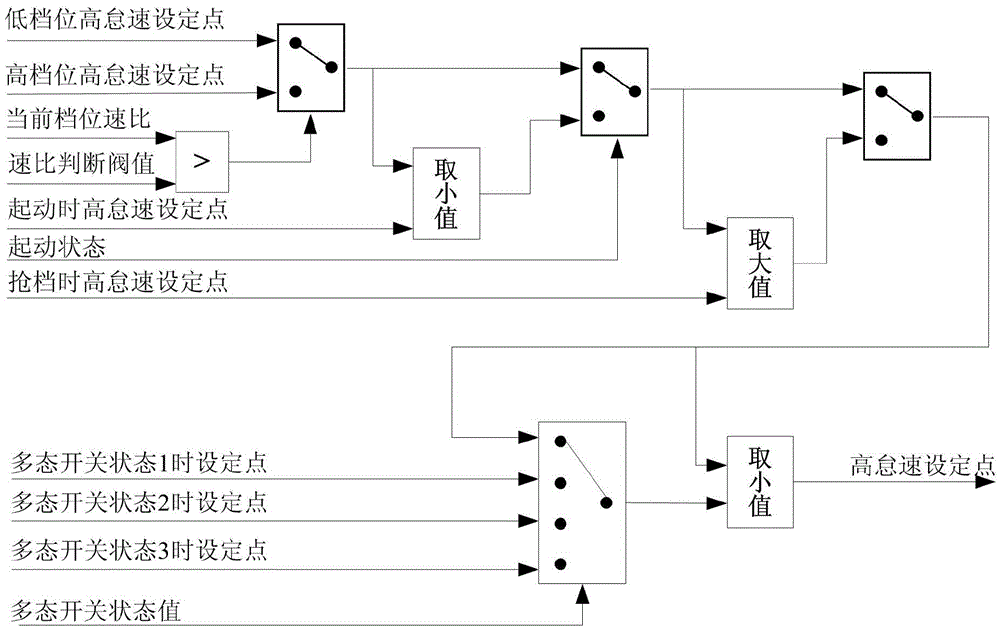

[0077] a. Acquisition of high idle speed set point: first take the current gear speed ratio and the speed ratio judgment threshold as input values, and then compare the current gear speed ratio with the speed ratio judgment threshold to judge whether the gear is in a high-end range or a low gear and then obtain the high idle speed set point of the gear according to the gear area where the gear is located. At this time, the high idle speed set point of the gear is the high idle speed set point; The minimum value between the high idle speed set point and the high idle speed set point at startup is taken as the high idle speed set point; when the gear is overtaken, the maximum value between the high idle speed set point of the gear pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com