Linear sliding rail with six columns of rolling balls

A linear slide, ball type technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve the problem of not being able to significantly improve the load capacity, poor load capacity, and poor ability to withstand side loads. , to achieve the effect of improving production efficiency and economic benefits, and simplifying processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

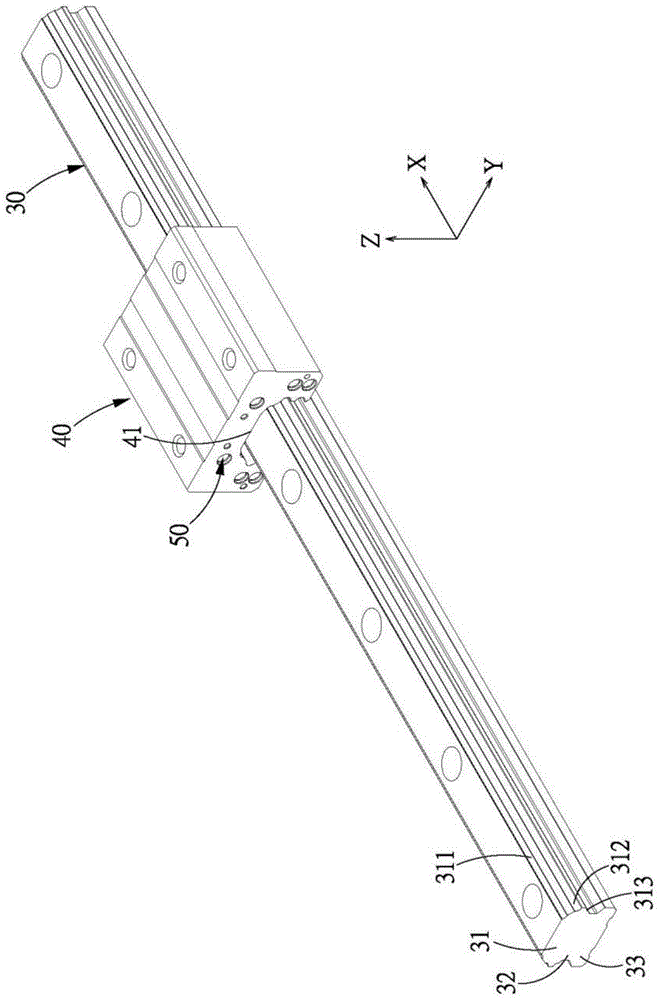

[0041] A preferred embodiment of the six-row ball linear slide rail of the present invention is as follows Figures 3 to 8 shown, including:

[0042] A slide rail 30 is a long strip block structure extending along an X direction, and a Y direction and a Z direction are defined perpendicular to the X direction, and the Y direction is perpendicular to the Z direction, and the slide rail 30 is composed of the Viewed from the end faces of both ends in the X direction, the slide rail 30 as a whole is a structure symmetrically arranged with respect to a symmetry axis L; and the slide rail 30 is sequentially divided into a head 31 and a neck in the Z direction. 32 and a bottom 33, the head 31 is upward in the Z direction compared to the bottom 33, and the bottom 33 is downward in the Z direction compared to the head 31, and the head 31 is in the The maximum width in the Y direction is a head width W1, the minimum width of the neck 32 in the Y direction is a neck width W2, and the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com