A vibration-damping structure applied to the acoustic self-guided array at the end of a rocket

A vibration-damping structure and sound-based array technology, which is applied in the direction of shock absorbers, spring/shock absorber design features, shock absorbers, etc., can solve the problems of inability to track and locate targets, reduced self-guidance accuracy, and interference with sound-based array receiving targets Echo signal and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

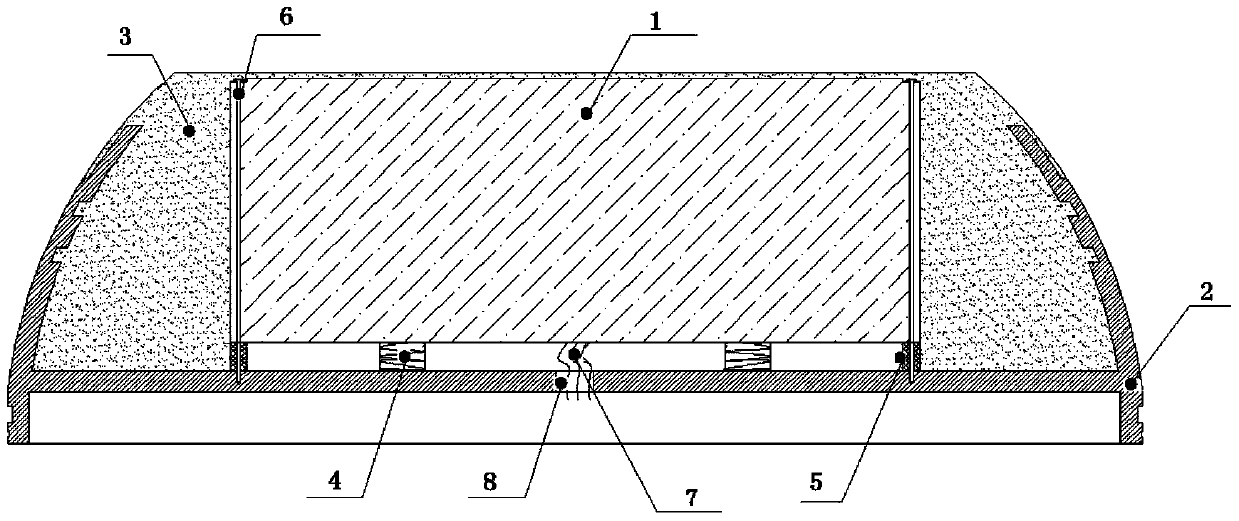

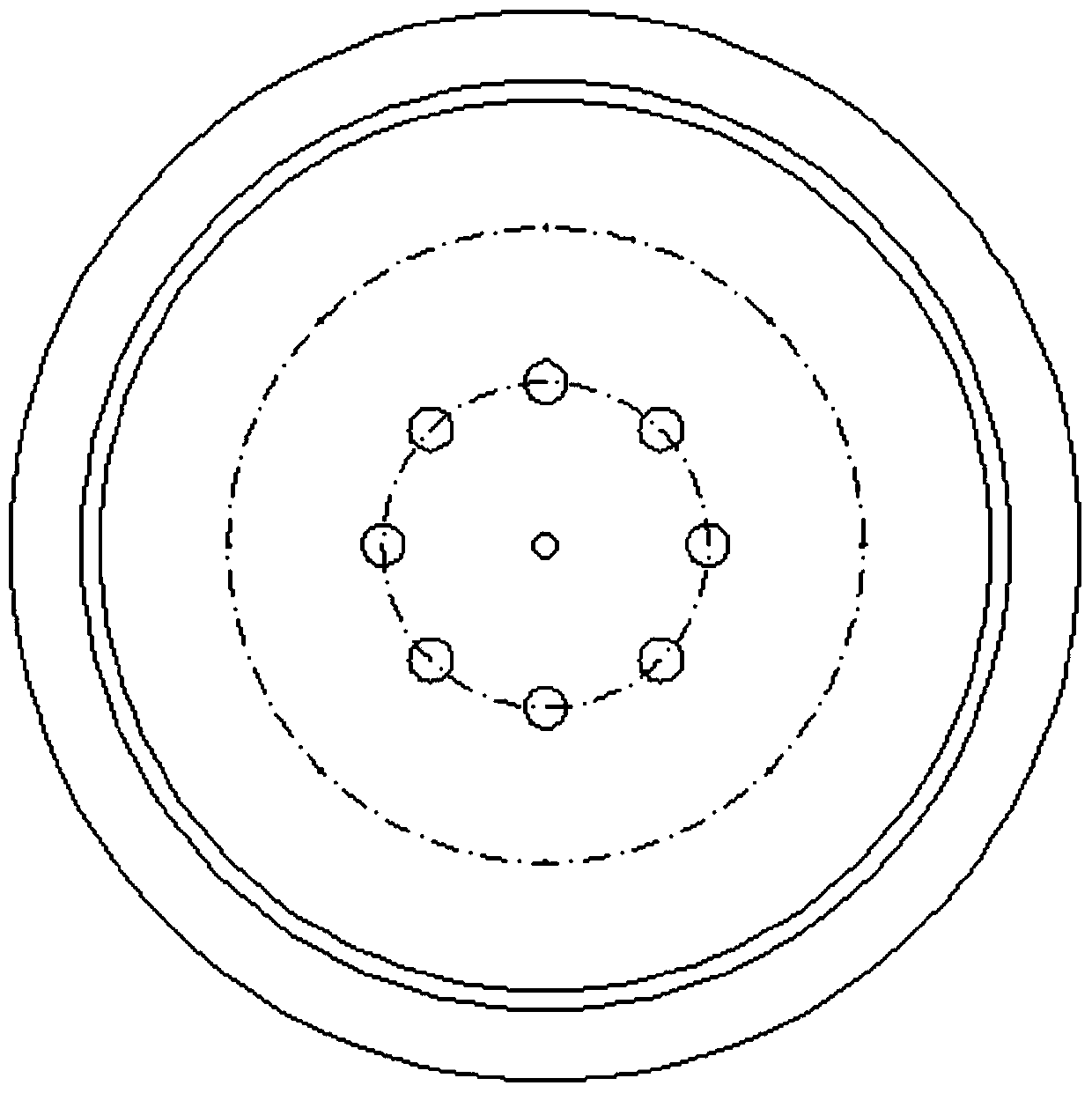

[0019] as attached figure 1 and 2 As shown, the present invention provides a damping structure applied to the acoustic self-guiding base array at the end of the rocket, the damping structure includes an acoustic base array unit 1, a base 2, a vibration isolation rubber 3, a compression spring 4, and a sealing gasket 5 and screw 6;

[0020] The bottom surface of the base 2 is processed with eight threaded holes that cooperate with the screw rod 6;

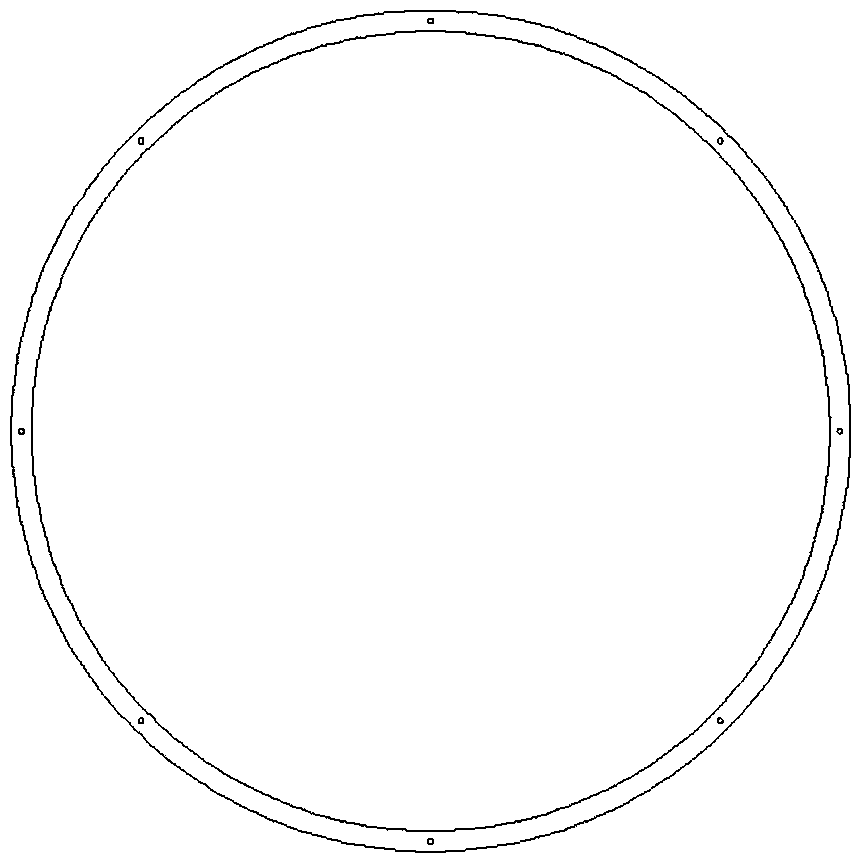

[0021] Both the sound-based array unit 1 and the sealing gasket 5 are processed with eight via holes, the positions of the via holes correspond to the positions of the threaded holes on the bottom surface of the base 2, and the shape and structure of the sealing gasket 5 are as shown in the attached image 3 shown;

[0022] The sound-based array unit is restricted on the inner surface of the base after the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com