Side mold and hub low-temperature casting mold

A side mold and cooling circuit technology, applied in the field of casting molds, can solve problems such as long solidification time, low casting efficiency, and temperature gradients that cannot meet production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

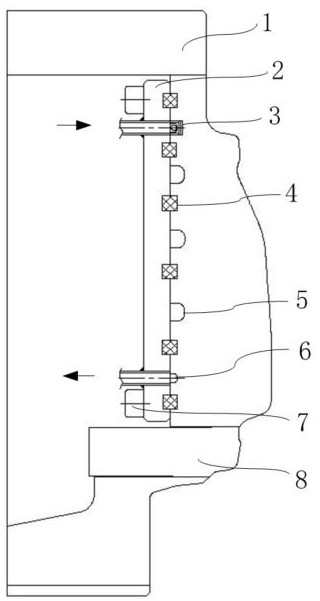

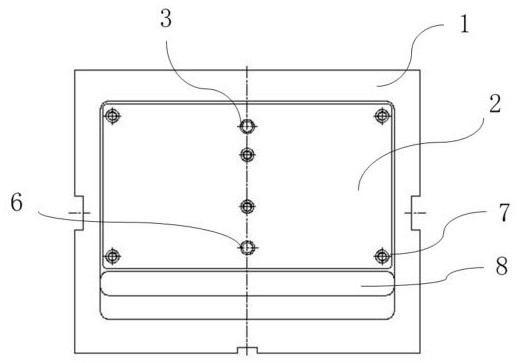

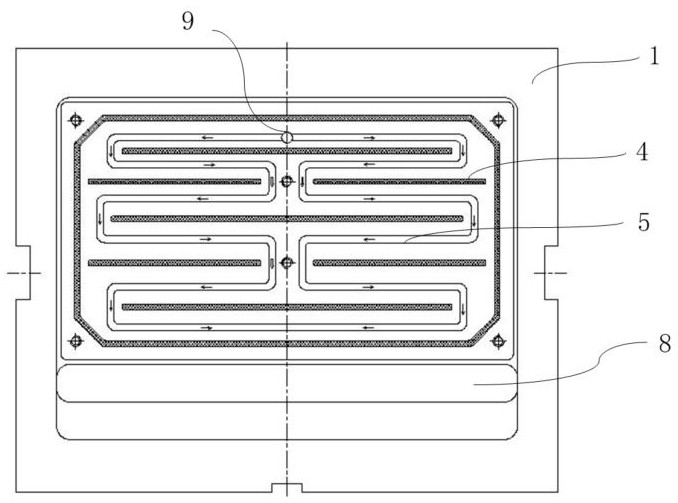

[0027] Combined with the manual Figure 1-5 , a side mold is provided in Embodiment 1, such as figure 1 As shown in the middle sectional view, it includes a side formwork frame 1, a cooling cover plate 2, an inlet pipe 3, an outlet pipe 6, a thermal insulation gasket 4, a channel 5, and a cooling insert 8. The side form frame 1 is made of cast mold steel, and a cooling circuit is processed in the back cavity of the side form frame 1, and the cooling circuit includes a plurality of parallel passages 5, and the adjacent passages along the solidification direction of the casting The spacing between 5 gradually increases. The channels 5 are arc-shaped grooves along the circumference of the side mold, and the distance between adjacent arc-shaped grooves increases gradually along the solidification direction of the casting (for example, the solidification direction of the rim, from top to bottom).

[0028] Such as image 3 As shown in , sealing grooves are arranged around the coo...

Embodiment 2

[0039] Embodiment 2 of the present application provides a wheel hub low-pressure casting mold, including a top mold, a bottom mold and four side molds 15 described in any of the above-mentioned embodiments, and the top mold, bottom mold and four Described side mold 15 encloses the mold cavity that forms low-pressure casting. The combined structure of described side mold 15 is as Figure 6 shown in . In other embodiments, according to the requirements of the cast product, the sideform structure can be integrated or a combination of more than one piece.

[0040] In this embodiment 2, the side mold in the above-mentioned embodiment is adopted, and cooling is performed on the original temperature gradient formed due to the thickness of the side mold, and the distance between the arc-shaped groove passages in the cooling circuit is gradually increased along the solidification direction. The ability to take away heat changes from strong to weak, and can be superimposed with the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com