Vent cap and its applied reducer

A vent cap, vent hole technology, applied in mechanical equipment, belt/chain/gear, transmission parts, etc., can solve the problems of oil leakage, oil waste, easy splashing of oil, etc., to avoid overflow, prevent The effect of improving oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The core of the present invention is to provide a breather cap, the oil leakage resistance of the breather cap is improved. Another core of the present invention is to provide a speed reducer including the above vent cap.

[0026] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

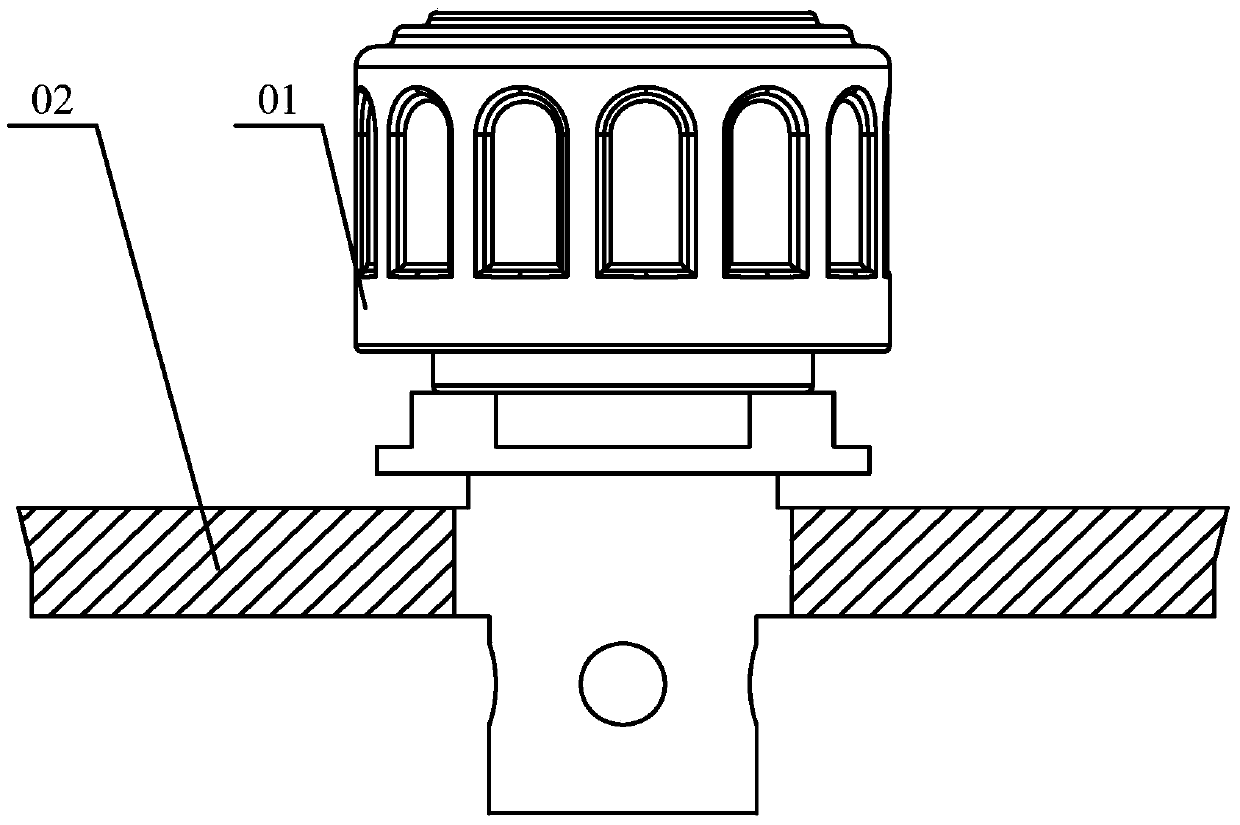

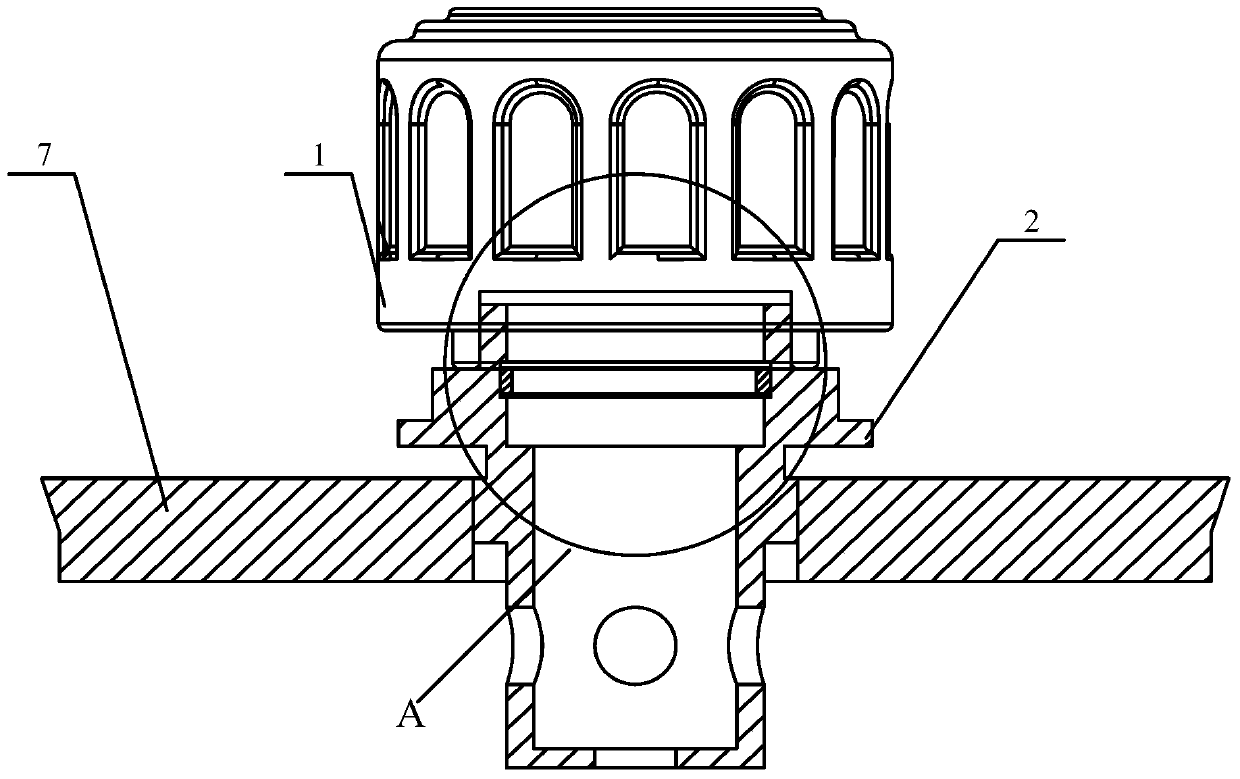

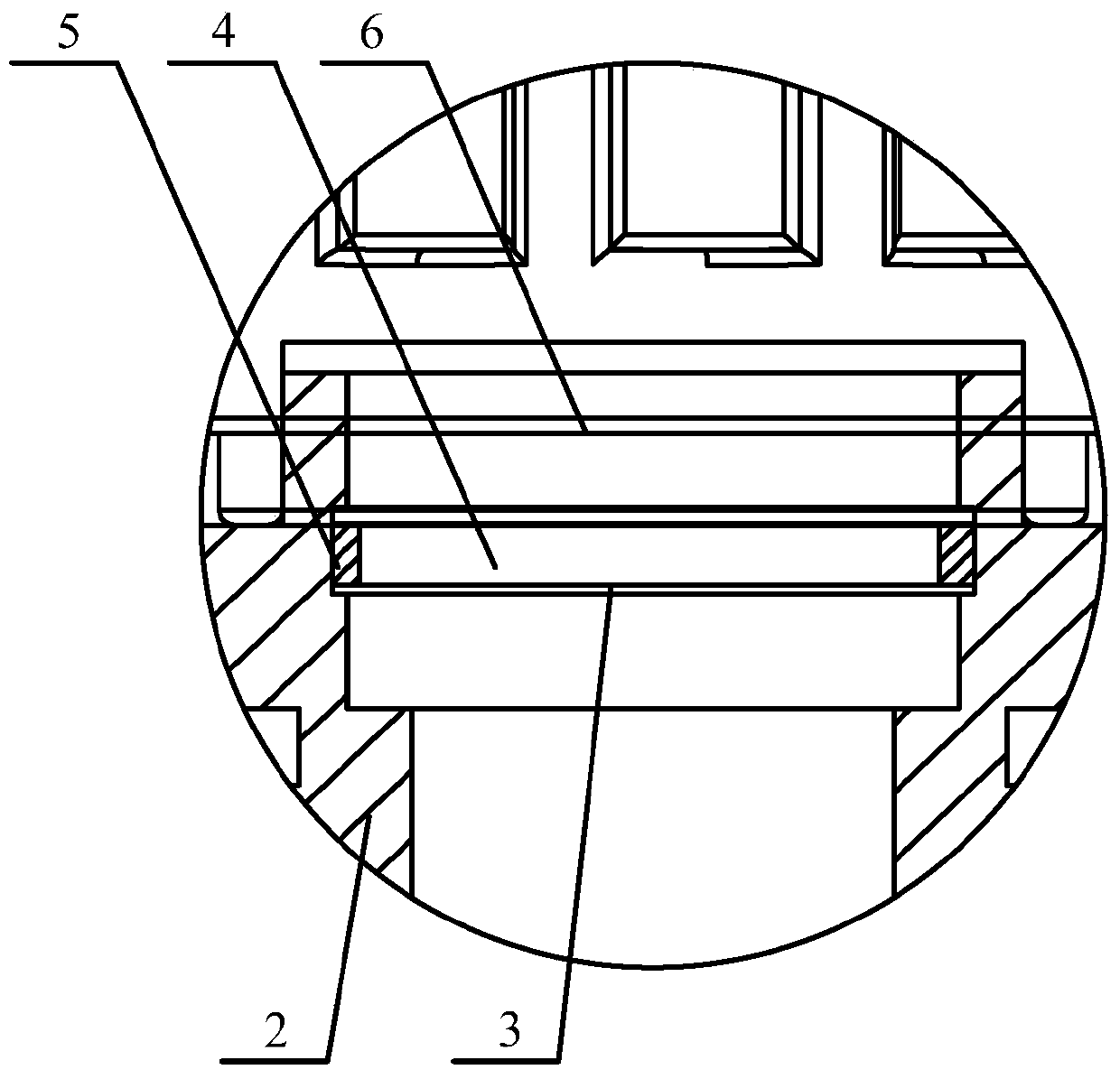

[0027] Please refer to Figure 2 to Figure 4 , in a specific embodiment, the vent cap provided by the present invention includes a vent cap body 1, a filter element 4, and a connector 2, and the vent cap body 1 is provided with a first vent hole connecting the internal cavity of the device with the outside atmosphere, connecting Part 2 is provided with a second vent hole, the second vent hole is a stepped hole, the two ends of the second vent hole are respectively connected with the first vent hole and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com