One-way clutch and starter

A one-way clutch, one-sided technology, applied in one-way clutches, clutches, machines/engines, etc., can solve problems that affect the service life of one-way clutches and starters, insufficient friction between metal gaskets and outer races, and easy grease Seepage and other problems, to achieve the effect of convenient automatic feeding of the production line, saving parts, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

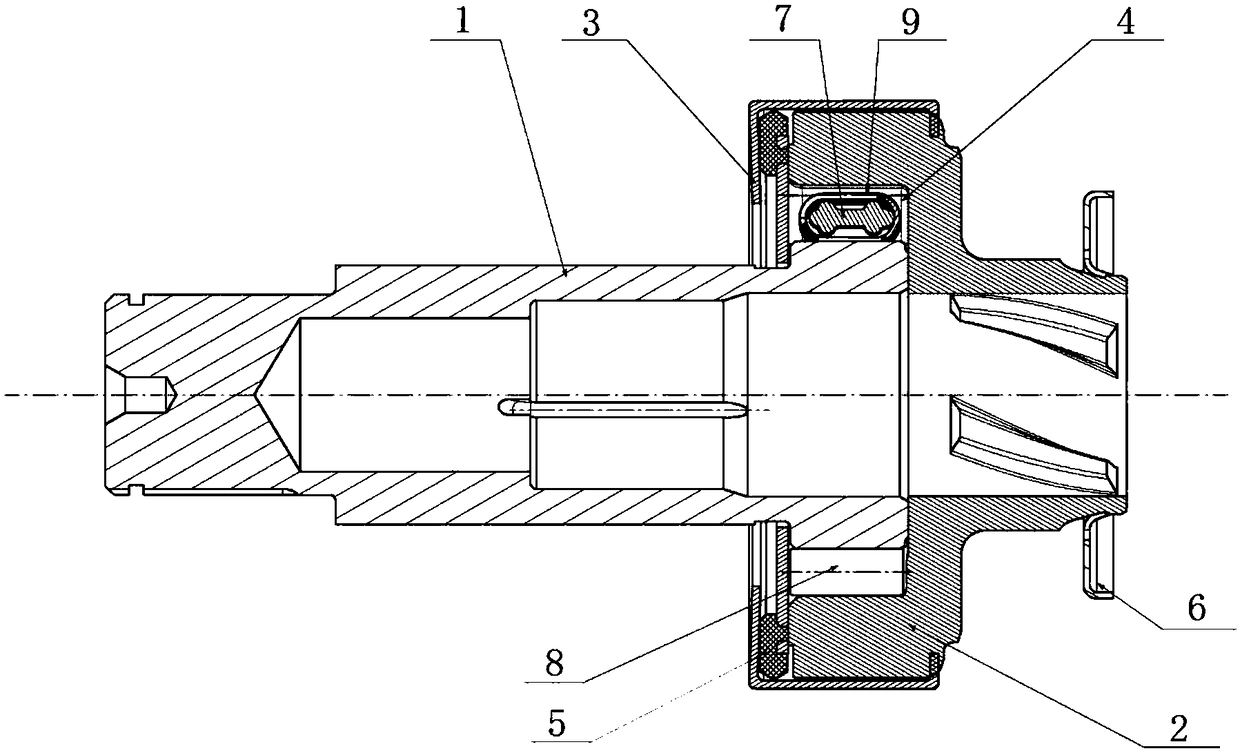

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only the parts related to the present invention are shown in the drawings but not all of them.

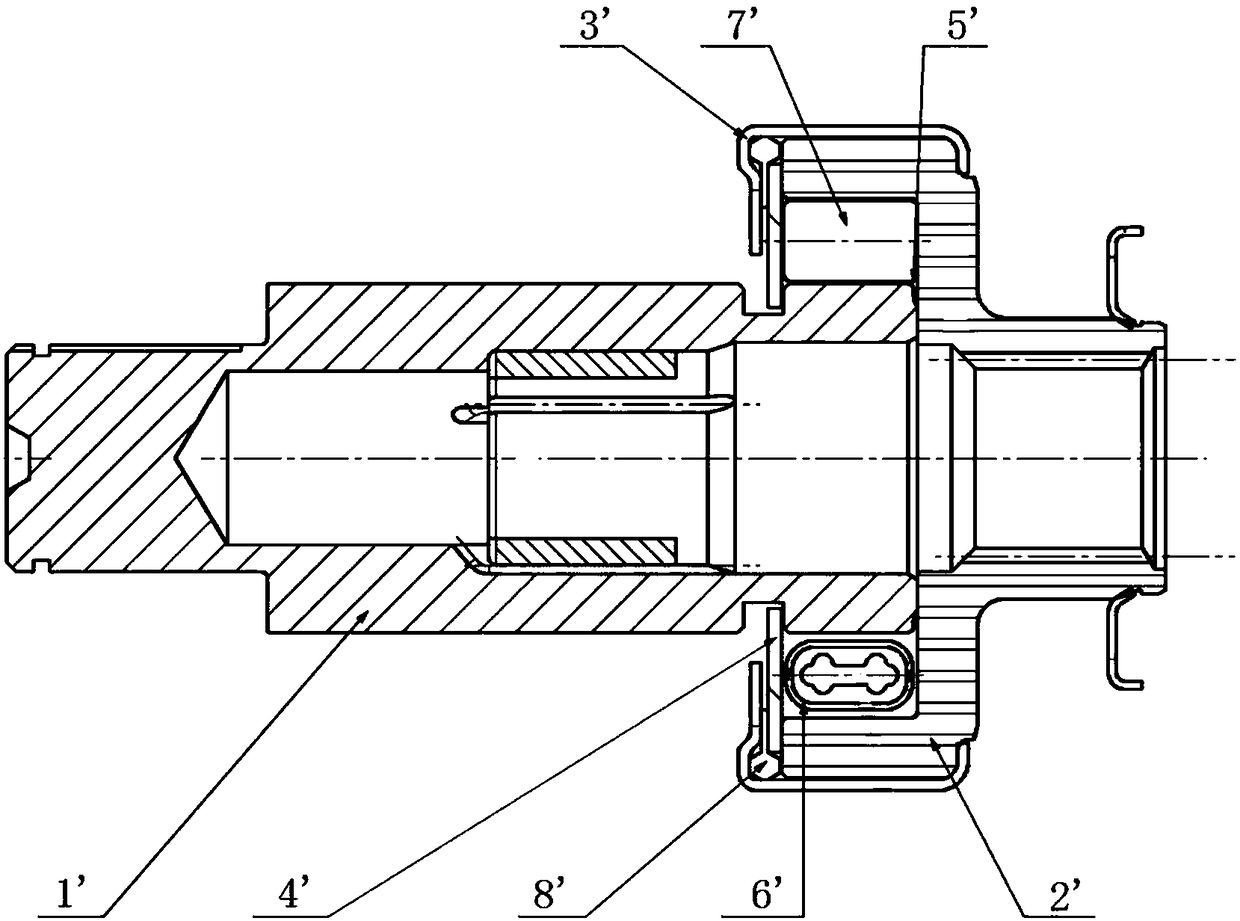

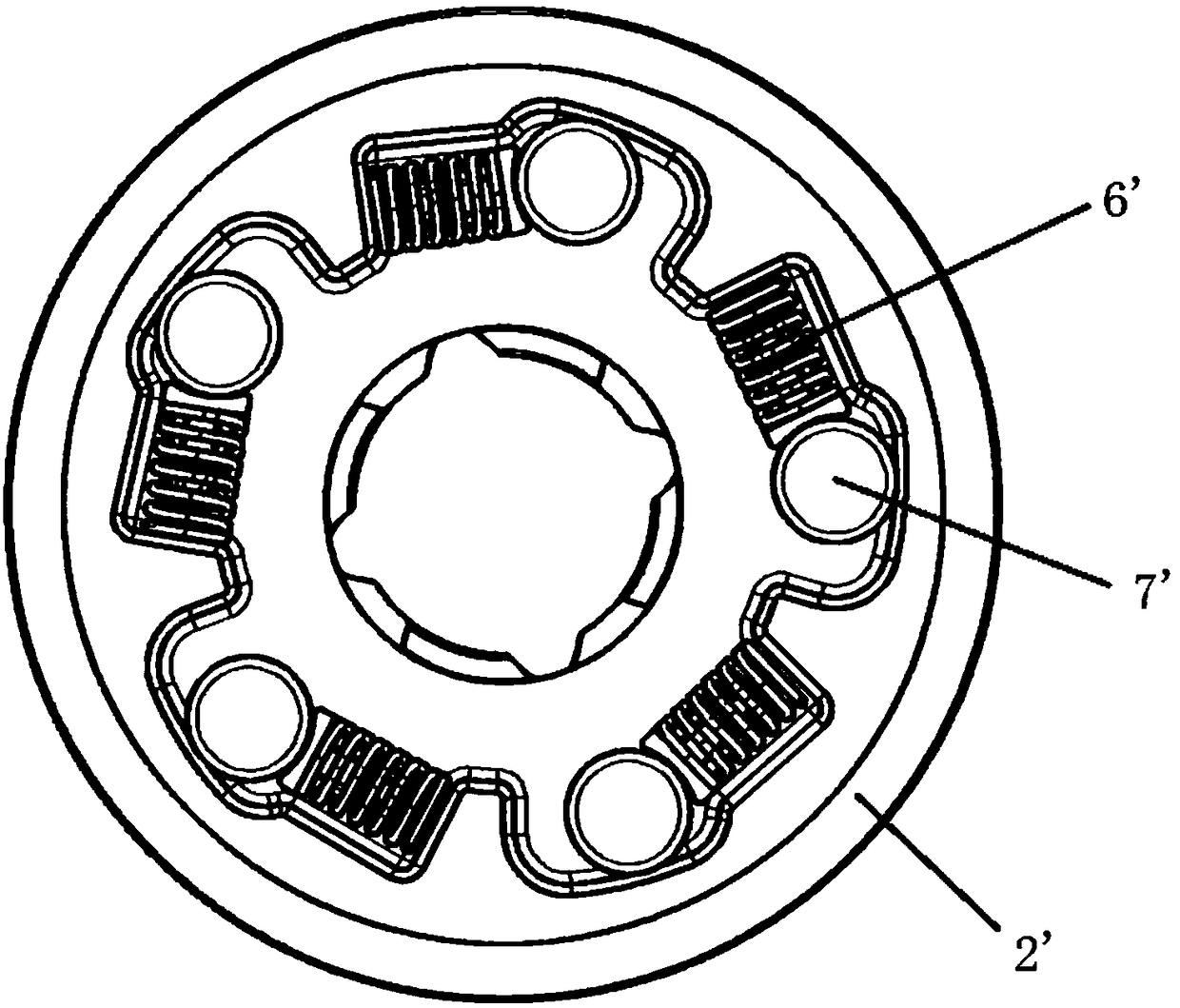

[0037] This embodiment proposes a one-way clutch, such as Figure 2-5 As shown, it includes a gear 1, an outer race 2, a casing 3 and an anti-rotation gasket 5. The gear 1 is provided with a shaft hole along its axis, and one end of the outer race 2 is sleeved on the tail end of the gear 1. The surface of the tail end of 1 fits the surface of the inner cavity of the outer race 2; the inner peripheral surface of the outer race 2 is provided with several wedge-shaped grooves at intervals, and the outer perip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com